Interviews

MIT develops system to let objects change colours

20 Sep '19

4 min read

Pic: Massachusetts Institute of Technology

Scientists from MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL) have developed a system that uses reprogrammable ink to let objects change colours when exposed to ultraviolet (UV) and visible light sources. Called “PhotoChromeleon,” the system uses a mix of photochromic dyes that can be sprayed or painted onto the surface of any object.

The process if fully reversible that can be repeated infinitely. PhotoChromeleon can be used to customise anything from a phone case to a car, or shoes that need an update. The colour remains, even when used in natural environments.

“This special type of dye could enable a whole myriad of customisation options that could improve manufacturing efficiency and reduce overall waste,” says CSAIL postdoc Yuhua Jin, the lead author on a new paper about the project. “Users could personalise their belongings and appearance on a daily basis, without the need to buy the same object multiple times in different colours and styles.”

PhotoChromeleon builds off of the team’s previous system, “ColorMod,” which uses a 3-D printer to fabricate items that can change their colour. Frustrated by some of the limitations of this project, such as small colour scheme and low-resolution results, the team decided to investigate potential updates.

With ColorMod, each pixel on an object needed to be printed, so the resolution of each tiny little square was somewhat grainy. As far as colours, each pixel of the object could only have two states: transparent and its own colour. So, a blue dye could only go from blue to transparent when activated, and a yellow dye could only show yellow.

But with PhotoChromeleon’s ink, one can create anything from a zebra pattern to a sweeping landscape to multicoloured fire flames, with a larger host of colours.

The team created the ink by mixing cyan, magenta, and yellow (CMY) photochromic dyes into a single sprayable solution, eliminating the need to painstakingly 3-D print individual pixels. By understanding how each dye interacts with different wavelengths, the team was able to control each colour channel through activating and deactivating with the corresponding light sources.

Specifically, they used three different lights with different wavelengths to eliminate each primary colour separately. For example, if one uses a blue light, it would mostly be absorbed by the yellow dye and be deactivated, and magenta and cyan would remain, resulting in blue. If one usse a green light, magenta would mostly absorb it and be deactivated, and then both yellow and cyan would remain, resulting in green.

After coating an object using the solution, the user simply places the object inside a box with a projector and UV light. The UV light saturates the colours from transparent to full saturation, and the projector desaturates the colours as needed. Once the light has activated the colours, the new pattern appears. But if one is not satisfied with the design, one can use the UV light to erase it, and start over.

They also developed a user interface to automatically process designs and patterns that go onto desired items. The user can load up their blueprint, and the programme generates the mapping onto the object before the light works its magic.

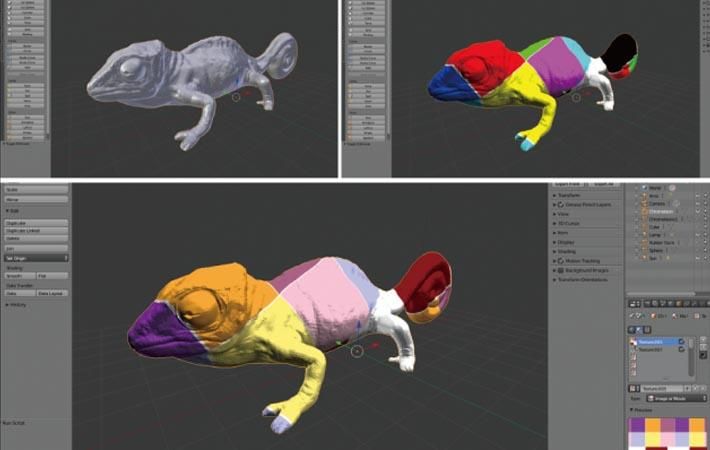

The team tested the system on a car model, a phone case, a shoe, and a little (toy) chameleon. Depending on the shape and orientation of the object, the process took anywhere from 15 to 40 minutes, and the patterns all had high resolutions and could be successfully erased when desired.

“By giving users the autonomy to individualise their items, countless resources could be preserved, and the opportunities to creatively change your favourite possessions are boundless,” says MIT Professor Stefanie Mueller.

While PhotoChromeleon opens up a much larger colour gamut, not all colours were represented in the photochromic dyes. For example, there was no great match for magenta or cyan, so the team had to estimate to the closest dye. They plan to expand on this by collaborating with material scientists to create improved dyes.

“We believe incorporation of novel, multi-photochromic inks into traditional materials can add value to Ford products by reducing the cost and time required for fabricating automotive parts,” says Alper Kiziltas, technical specialist of sustainable and emerging materials at Ford Motor (Ford has been working with MIT on the ColorMod 3-D technology through an alliance collaboration.) “This ink could reduce the number of steps required for producing a multicolour part, or improve the durability of the colour from weathering or UV degradation. One day, we might even be able to personalise our vehicles on a whim.” (SV)

The process if fully reversible that can be repeated infinitely. PhotoChromeleon can be used to customise anything from a phone case to a car, or shoes that need an update. The colour remains, even when used in natural environments.

“This special type of dye could enable a whole myriad of customisation options that could improve manufacturing efficiency and reduce overall waste,” says CSAIL postdoc Yuhua Jin, the lead author on a new paper about the project. “Users could personalise their belongings and appearance on a daily basis, without the need to buy the same object multiple times in different colours and styles.”

PhotoChromeleon builds off of the team’s previous system, “ColorMod,” which uses a 3-D printer to fabricate items that can change their colour. Frustrated by some of the limitations of this project, such as small colour scheme and low-resolution results, the team decided to investigate potential updates.

With ColorMod, each pixel on an object needed to be printed, so the resolution of each tiny little square was somewhat grainy. As far as colours, each pixel of the object could only have two states: transparent and its own colour. So, a blue dye could only go from blue to transparent when activated, and a yellow dye could only show yellow.

But with PhotoChromeleon’s ink, one can create anything from a zebra pattern to a sweeping landscape to multicoloured fire flames, with a larger host of colours.

The team created the ink by mixing cyan, magenta, and yellow (CMY) photochromic dyes into a single sprayable solution, eliminating the need to painstakingly 3-D print individual pixels. By understanding how each dye interacts with different wavelengths, the team was able to control each colour channel through activating and deactivating with the corresponding light sources.

Specifically, they used three different lights with different wavelengths to eliminate each primary colour separately. For example, if one uses a blue light, it would mostly be absorbed by the yellow dye and be deactivated, and magenta and cyan would remain, resulting in blue. If one usse a green light, magenta would mostly absorb it and be deactivated, and then both yellow and cyan would remain, resulting in green.

After coating an object using the solution, the user simply places the object inside a box with a projector and UV light. The UV light saturates the colours from transparent to full saturation, and the projector desaturates the colours as needed. Once the light has activated the colours, the new pattern appears. But if one is not satisfied with the design, one can use the UV light to erase it, and start over.

They also developed a user interface to automatically process designs and patterns that go onto desired items. The user can load up their blueprint, and the programme generates the mapping onto the object before the light works its magic.

The team tested the system on a car model, a phone case, a shoe, and a little (toy) chameleon. Depending on the shape and orientation of the object, the process took anywhere from 15 to 40 minutes, and the patterns all had high resolutions and could be successfully erased when desired.

“By giving users the autonomy to individualise their items, countless resources could be preserved, and the opportunities to creatively change your favourite possessions are boundless,” says MIT Professor Stefanie Mueller.

While PhotoChromeleon opens up a much larger colour gamut, not all colours were represented in the photochromic dyes. For example, there was no great match for magenta or cyan, so the team had to estimate to the closest dye. They plan to expand on this by collaborating with material scientists to create improved dyes.

“We believe incorporation of novel, multi-photochromic inks into traditional materials can add value to Ford products by reducing the cost and time required for fabricating automotive parts,” says Alper Kiziltas, technical specialist of sustainable and emerging materials at Ford Motor (Ford has been working with MIT on the ColorMod 3-D technology through an alliance collaboration.) “This ink could reduce the number of steps required for producing a multicolour part, or improve the durability of the colour from weathering or UV degradation. One day, we might even be able to personalise our vehicles on a whim.” (SV)

Fibre2Fashion News Desk – India

Popular News

Leave your Comments

Jason Kent

British Textile Machinery Association (BTMA)

-Ltd..jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)