Interviews

Burdwan keeps Mughal era handloom tradition alive

15 Jul '10

6 min read

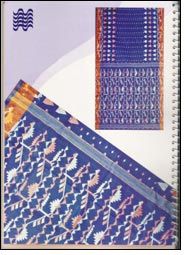

In those days (Mughals &Nawabs), the bleaching & dyeing techniques were carried out by indigenous method due to non availability of chemical dyes and ingredients the technique of weaving Jamdani figured designs may be call "PICK & PICK" i.e., one pick extra weft design and then one ground pick.

It originated from Tangail, a district presently in Bangladesh. Previously it was named as "Begum Bahar" where silk warp and cotton weft were used. Later on, both cotton warp and weft were in vogue.

The weaver mainly of 'BASAK' community who migrated from Tangail district before partition of India & settled in Katwa Dhatrigram, Tamaghata, Samudragarh, area in Burdwan district.

At present, silk Tangail sarees have been revived.

The technique of drawing and weaving of extra weft for figured Tangail sarees is more or less identical to Jamdani sarees. Unlike Jamdani, two plain picks instead of a single pick are inserted after each extra weft meant for figured design.

Now in Samudragarh and Dhatrigram region, design on Tangail sarees are woven boarder by using Jacquard. The recent development is its decorative design. The main characteristics of these sarees is in the loom finishing. While weaving Tangail saree , a sort of finishing by putting starch is done in addition to sizing on cotton yarn. Other feature of this saree i.e. paper finish appearance depends on its surface texture.

In recent time handloom weavers have diversified the Tangail saree in to the following varieties:

* Tangail Naksapar with jacquard design.

* Tangail (silk x silk ) sarees.

There are about 94,000 people at Burdwan cluster engaged on part-time or full-time basis in handloom activities. Besides this, there are a remarkable number of designers, dyers, card makers, traders and auxiliary support providers. Approximate 60% of weaver force is from the adjacent villages of the cluster while 40% weavers are from outside, mainly from North Bengal District.

Weaving community is largely concentrated at Ketugram, Ghoshhat, Panuhat, Musthali, Tamaghat, Kamalnagar, Mertala, Purulia, Serampore, Vidyanagar, Hatsimla, Nasratpur, Goalpara and Dhatrigram areas.

Before partition of Bengal i.e. in the year 1942, 12- 14 families of weaving community from 'Nowakhali' and Tangail (presently Bangladesh) district came along-with their looms and concentrated at Hatsimla, Dhatigtram, and Nasratpur area. They specialized in weaving of Tangail designed sarees with finer counts of yarn mainly imported varieties.

At that time, weavers used to get their yarn from Dhakkai Patti at Kolkata and also sell their finished products to that 'patti' only. Each of the weaving manifested areas i.e., Kalna & Katwa sub division has its own history.

The main products in these two different sub-divisions vary in their quality, variety and individuality. This has been caused due to different factors. For instance the raw materials by which the Katwa belt weavers turn out their products are coarser variety of material.

It originated from Tangail, a district presently in Bangladesh. Previously it was named as "Begum Bahar" where silk warp and cotton weft were used. Later on, both cotton warp and weft were in vogue.

The weaver mainly of 'BASAK' community who migrated from Tangail district before partition of India & settled in Katwa Dhatrigram, Tamaghata, Samudragarh, area in Burdwan district.

At present, silk Tangail sarees have been revived.

The technique of drawing and weaving of extra weft for figured Tangail sarees is more or less identical to Jamdani sarees. Unlike Jamdani, two plain picks instead of a single pick are inserted after each extra weft meant for figured design.

Now in Samudragarh and Dhatrigram region, design on Tangail sarees are woven boarder by using Jacquard. The recent development is its decorative design. The main characteristics of these sarees is in the loom finishing. While weaving Tangail saree , a sort of finishing by putting starch is done in addition to sizing on cotton yarn. Other feature of this saree i.e. paper finish appearance depends on its surface texture.

In recent time handloom weavers have diversified the Tangail saree in to the following varieties:

* Tangail Naksapar with jacquard design.

* Tangail (silk x silk ) sarees.

There are about 94,000 people at Burdwan cluster engaged on part-time or full-time basis in handloom activities. Besides this, there are a remarkable number of designers, dyers, card makers, traders and auxiliary support providers. Approximate 60% of weaver force is from the adjacent villages of the cluster while 40% weavers are from outside, mainly from North Bengal District.

Weaving community is largely concentrated at Ketugram, Ghoshhat, Panuhat, Musthali, Tamaghat, Kamalnagar, Mertala, Purulia, Serampore, Vidyanagar, Hatsimla, Nasratpur, Goalpara and Dhatrigram areas.

Before partition of Bengal i.e. in the year 1942, 12- 14 families of weaving community from 'Nowakhali' and Tangail (presently Bangladesh) district came along-with their looms and concentrated at Hatsimla, Dhatigtram, and Nasratpur area. They specialized in weaving of Tangail designed sarees with finer counts of yarn mainly imported varieties.

At that time, weavers used to get their yarn from Dhakkai Patti at Kolkata and also sell their finished products to that 'patti' only. Each of the weaving manifested areas i.e., Kalna & Katwa sub division has its own history.

The main products in these two different sub-divisions vary in their quality, variety and individuality. This has been caused due to different factors. For instance the raw materials by which the Katwa belt weavers turn out their products are coarser variety of material.

Popular News

Leave your Comments

Editor’s Pick

Pratik Gadia

The Yarn Bazaar - Filosha Infotech Private Limited

Therese Premler-Andersson

Textile Machinery Association of Sweden (TMAS)

-Ltd..jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)