Interviews

News Flash

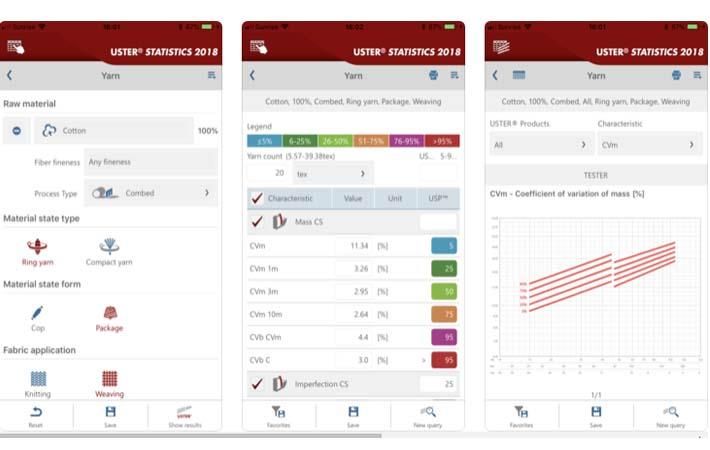

Uster Statistics mobile app gives new insights on spinning

14 Dec '18

2 min read

Courtesy: Uster

Uster, the high-technology instrument manufacturer of products for quality management for the textile industry, has released the new 2018 edition of Uster Statistics mobile application. The application delivers a new user experience, with simple, intuitive handling. It also comes with extended datasets and analyses, based on testing of thousands of samples.

“With the new mobile app, we are proud to present a virtually seamless blended yarn range. Users can enter their chosen blend ratio in 1per cent steps. After entering the ratio, the graph with relevant quality data is selected, based on an intelligent algorithm running in the background. This feature fulfils requests from many users for more coverage of blended yarn types in Uster Statistics,” Iris Biermann, Uster’s head of textile technologies said in a media statement.

The HL sensor of Uster Tester 6 offers new values which provide a clear business advantage, as there is a strong correlation between yarn hairiness and fabric behaviour. If spinners compare the new hairiness values provided by the Tester with Uster Statistics 2018, they will, for example, obtain more sensitive indicators about traveller change cycles. Trials have shown that a mill can optimise traveller change cycles based on the S1+2u values – saving money and extending traveller working lifetimes. At the same time, the yarn quality stays consistent at the required level and fabric appearance does not change either.

Speaking on the improvements that can be achieved by studying the Statistics data she said, “For Uster Statistics 2018, we used a new source for sliver and roving data. These are now based on Uster Tester generations 5 and 6. Personally, I recommend greater use of the Statistics to evaluate sliver and roving quality, with respect to evenness. A finisher sliver with poor evenness will be incapable of producing a yarn with good evenness. We know this from general experience. From a low quality finisher sliver, a low quality roving will be produced, ending up with a yarn of low quality, based on the evenness level.” (GK)

“With the new mobile app, we are proud to present a virtually seamless blended yarn range. Users can enter their chosen blend ratio in 1per cent steps. After entering the ratio, the graph with relevant quality data is selected, based on an intelligent algorithm running in the background. This feature fulfils requests from many users for more coverage of blended yarn types in Uster Statistics,” Iris Biermann, Uster’s head of textile technologies said in a media statement.

The HL sensor of Uster Tester 6 offers new values which provide a clear business advantage, as there is a strong correlation between yarn hairiness and fabric behaviour. If spinners compare the new hairiness values provided by the Tester with Uster Statistics 2018, they will, for example, obtain more sensitive indicators about traveller change cycles. Trials have shown that a mill can optimise traveller change cycles based on the S1+2u values – saving money and extending traveller working lifetimes. At the same time, the yarn quality stays consistent at the required level and fabric appearance does not change either.

Speaking on the improvements that can be achieved by studying the Statistics data she said, “For Uster Statistics 2018, we used a new source for sliver and roving data. These are now based on Uster Tester generations 5 and 6. Personally, I recommend greater use of the Statistics to evaluate sliver and roving quality, with respect to evenness. A finisher sliver with poor evenness will be incapable of producing a yarn with good evenness. We know this from general experience. From a low quality finisher sliver, a low quality roving will be produced, ending up with a yarn of low quality, based on the evenness level.” (GK)

Fibre2Fashion News Desk – India

Popular News

Leave your Comments

Editor’s Pick

-Ltd..jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)