Interviews

Mitsubishi working on para-xylene project

20 Jul '20

2 min read

Pic: Shutterstock

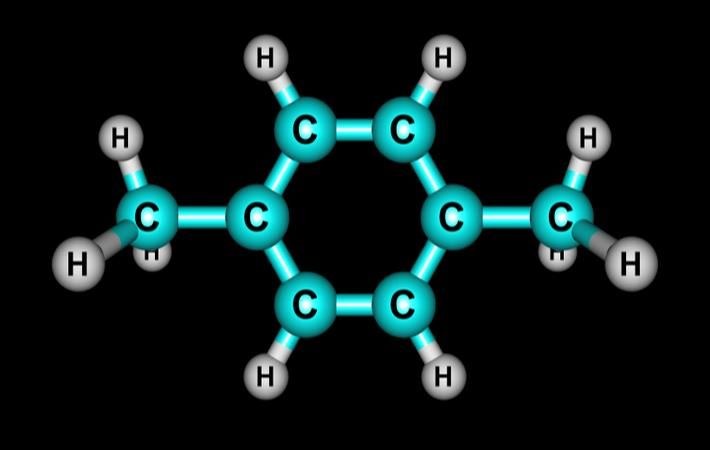

University of Toyama, Chiyoda Corporation, Nippon Steel Engineering Co, Nippon Steel Corporation, HighChem Company, and Mitsubishi Corporation have been selected as contractor for a project to develop technology for para-xylene production from carbon dioxide. Para-xylene is a raw material, currently obtained from petrochemicals, for synthetic textiles.

The group will improve the innovative catalyst for the production of para-xylene from carbon dioxide, develop a way to mass-produce the catalyst, and develop the process while studying its feasibility including its overall economic efficiency and carbon dioxide reduction effect in order to pave the way to the demonstration stage.

In order to cope with global climate change, it is necessary to address the issue of carbon dioxide emissions from factories, power plants, and various emission sources while pursuing all possible technological options including carbon recycling technologies.

The initiaive "Roadmap for Carbon Recycling Technologies" formulated by METI (Ministry of Economy, Trade and Industry) in June 2019 sets forth guidelines for utilisation of carbon recycling technologies for separating and collecting carbon dioxide as resources and reusing it in the form of diverse carbon compounds for chemical materials or fuels.

Against this backdrop, NEDO (the New Energy and Industrial Technology Development Organisation) has launched a development project for the world's most advanced technology for industrial para-xylene production from carbon dioxide to substitute existing fossil fuel-derived chemicals, and the group has been selected as contractors for this commissioned project.

Para-xylene is a particularly important basic compound in the production of PTA which is a feedstock material for polyesters such as polyester fibres and plastic bottles. Due to its composition, it can be produced with a relatively small amount of hydrogen while fixing a large amount of carbon dioxide, compared to other compounds from carbon recycling. This is a theme with great potential from both economic and environmental perspectives.

The global demand for para-xylene is approximately 49 million tons per year. Assuming that the feedstock for para-xylene of the current demand level is entirely converted from fossil fuels to carbon dioxide, theoretically 160 million tons of carbon dioxide could be fixed in the para-xylene per year.

The group will improve the innovative catalyst for the production of para-xylene from carbon dioxide, develop a way to mass-produce the catalyst, and develop the process while studying its feasibility including its overall economic efficiency and carbon dioxide reduction effect in order to pave the way to the demonstration stage.

In order to cope with global climate change, it is necessary to address the issue of carbon dioxide emissions from factories, power plants, and various emission sources while pursuing all possible technological options including carbon recycling technologies.

The initiaive "Roadmap for Carbon Recycling Technologies" formulated by METI (Ministry of Economy, Trade and Industry) in June 2019 sets forth guidelines for utilisation of carbon recycling technologies for separating and collecting carbon dioxide as resources and reusing it in the form of diverse carbon compounds for chemical materials or fuels.

Against this backdrop, NEDO (the New Energy and Industrial Technology Development Organisation) has launched a development project for the world's most advanced technology for industrial para-xylene production from carbon dioxide to substitute existing fossil fuel-derived chemicals, and the group has been selected as contractors for this commissioned project.

Para-xylene is a particularly important basic compound in the production of PTA which is a feedstock material for polyesters such as polyester fibres and plastic bottles. Due to its composition, it can be produced with a relatively small amount of hydrogen while fixing a large amount of carbon dioxide, compared to other compounds from carbon recycling. This is a theme with great potential from both economic and environmental perspectives.

The global demand for para-xylene is approximately 49 million tons per year. Assuming that the feedstock for para-xylene of the current demand level is entirely converted from fossil fuels to carbon dioxide, theoretically 160 million tons of carbon dioxide could be fixed in the para-xylene per year.

Fibre2Fashion News Desk (SV)

Popular News

Leave your Comments

Kimberly Morgan and Rik Veltman

K3 Business Technology Group PLC

Pratik Gadia

The Yarn Bazaar - Filosha Infotech Private Limited

-Ltd..jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)