Interviews

News Flash

Fit3D unveils BodyBlock AI

10 Aug '18

4 min read

Courtesy: Fit3D

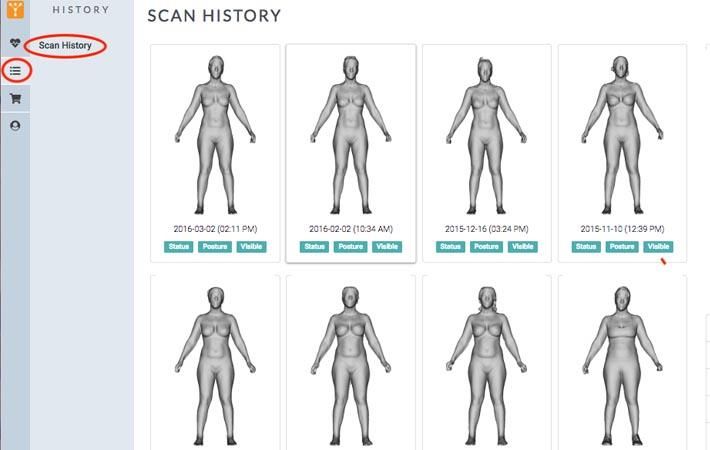

Fit3D, maker of the ProScanner 3D body surface scanner, has launched BodyBlock AI, its body scan data services for the apparel and garment industries. The company has processed 500,000 body scans using the Fit3D ProScanner. BodyBlock AI’s services are meant for those developing new clothing design and fit, eliminating the need of a traditional sizing study.

Retails companies lose billions every year due to improperly fitting clothes. This is a global issue with $64 billion in lost profits for apparel returned because of poor fit and $43 billion spent on revamping sizing charts for each of a brand’s product lines.

BodyBlock AI’s services are formulated for those integral in developing new clothing design and fit, eliminating the hassle and work of a traditional sizing study, working with the design team to understand the product lines and the data specifications needed to break down a size array. Design teams also have access to the actual 3D body scans via BodyBlock, so that they can be utilised during the design process, testing draping and fit.

“Fit3D can quickly capture accurate 3D human body avatars cost effectively.” said Marcus Ogawa, a managing partner of Quest Venture Partners. “They focus on using a one-of-a-kind proprietary dataset to help apparel and retail companies efficiently design and distribute clothing to fit their target audiences and they are the only real game in town with a billion dollar market potential in apparel alone.”

The global apparel industry, including online and brick-and-mortar sales, loses $100 billion each year due to poor fit. In addition to the monetary loss, there are hundreds of thousands of tons of material waste from returns, including fabric, wash, gas through shipping and logistics.

The problem impact more the online retailers who carry the added burden of both outbound and return shipping costs. Not only will the data improve fit for clothing during the design process, but apparel companies can also offer recommended fit for consumers. When packaged correctly using Fit3D’s data and machine learning (ML) capabilities, Fit3D can significantly reduce the monetary loss and waste - even a ten per cent reduction in returns could save retailers millions of dollars, improve margins, and shareholder value.

“We have produced a highly accurate 3D body scanner in order to generate the world’s largest and accurate 3D body scan database,” said Greg Moore, Fit3D co-founder and CEO. “Our vision from day one has been to leverage our body scanning services to build the largest, fastest growing, and most globally diverse 3D body avatar dataset in the world. Fit3D and clothing brands can utilise that data to help the world design and distribute more customised and better fitting clothing.”

“Using fit models is an expensive and lengthy process for garment makers and it usually doesn’t result in a good fit for most people,” said Tyler Carter, Fit3D co-founder and CTO. “The apparel industry needs a much larger data set in order to provide a better fit for their customers.”

The 500,000 body scans from Fit3D include scans from 45 countries and 47 US states. The fast-growing dataset is 65 per cent female and 35 per cent male with ages ranging from under 25 to 80. The Fit3D body avatar data will be available via four BodyBlock AI services - BodyBlock Sizing, BodyBlock Insights, BodyBlock Marketplace and

BodyBlock Predict.

“Prior to Fit3D, mass data for human bodies worldwide has never been available,” said Walden Lam, co-founder and chief hustler for denim unspun, a robotics and apparel company building custom jeans on-demand. “Garment companies have always struggled with finding sufficient data and it has proven to be a costly information gap. Most apparel companies spend months and hundreds of thousands of dollars to identify fit for a new item. Fit3D’s database with machine learning and predictive analytics is helping companies like us to create a scalable, mass customisation business.”

With the advancements in manufacturing and the Fit3D body data, mass and micro customisation is now possible and cost-effective for the garment industry. “When products and services are more accurately designed for and distributed to consumers, apparel and retail will operate more efficiently, while reducing waste and increasing profitability. Who doesn’t need that?” continued Moore.

More than 1200 Fit3D ProScanners are currently operating in 45 countries. Sales from direct selling and distributors have doubled from 2016 to 2017. The company is on-track to exceed 100 per cent sales growth in 2018. (SV)

Retails companies lose billions every year due to improperly fitting clothes. This is a global issue with $64 billion in lost profits for apparel returned because of poor fit and $43 billion spent on revamping sizing charts for each of a brand’s product lines.

BodyBlock AI’s services are formulated for those integral in developing new clothing design and fit, eliminating the hassle and work of a traditional sizing study, working with the design team to understand the product lines and the data specifications needed to break down a size array. Design teams also have access to the actual 3D body scans via BodyBlock, so that they can be utilised during the design process, testing draping and fit.

“Fit3D can quickly capture accurate 3D human body avatars cost effectively.” said Marcus Ogawa, a managing partner of Quest Venture Partners. “They focus on using a one-of-a-kind proprietary dataset to help apparel and retail companies efficiently design and distribute clothing to fit their target audiences and they are the only real game in town with a billion dollar market potential in apparel alone.”

The global apparel industry, including online and brick-and-mortar sales, loses $100 billion each year due to poor fit. In addition to the monetary loss, there are hundreds of thousands of tons of material waste from returns, including fabric, wash, gas through shipping and logistics.

The problem impact more the online retailers who carry the added burden of both outbound and return shipping costs. Not only will the data improve fit for clothing during the design process, but apparel companies can also offer recommended fit for consumers. When packaged correctly using Fit3D’s data and machine learning (ML) capabilities, Fit3D can significantly reduce the monetary loss and waste - even a ten per cent reduction in returns could save retailers millions of dollars, improve margins, and shareholder value.

“We have produced a highly accurate 3D body scanner in order to generate the world’s largest and accurate 3D body scan database,” said Greg Moore, Fit3D co-founder and CEO. “Our vision from day one has been to leverage our body scanning services to build the largest, fastest growing, and most globally diverse 3D body avatar dataset in the world. Fit3D and clothing brands can utilise that data to help the world design and distribute more customised and better fitting clothing.”

“Using fit models is an expensive and lengthy process for garment makers and it usually doesn’t result in a good fit for most people,” said Tyler Carter, Fit3D co-founder and CTO. “The apparel industry needs a much larger data set in order to provide a better fit for their customers.”

The 500,000 body scans from Fit3D include scans from 45 countries and 47 US states. The fast-growing dataset is 65 per cent female and 35 per cent male with ages ranging from under 25 to 80. The Fit3D body avatar data will be available via four BodyBlock AI services - BodyBlock Sizing, BodyBlock Insights, BodyBlock Marketplace and

BodyBlock Predict.

“Prior to Fit3D, mass data for human bodies worldwide has never been available,” said Walden Lam, co-founder and chief hustler for denim unspun, a robotics and apparel company building custom jeans on-demand. “Garment companies have always struggled with finding sufficient data and it has proven to be a costly information gap. Most apparel companies spend months and hundreds of thousands of dollars to identify fit for a new item. Fit3D’s database with machine learning and predictive analytics is helping companies like us to create a scalable, mass customisation business.”

With the advancements in manufacturing and the Fit3D body data, mass and micro customisation is now possible and cost-effective for the garment industry. “When products and services are more accurately designed for and distributed to consumers, apparel and retail will operate more efficiently, while reducing waste and increasing profitability. Who doesn’t need that?” continued Moore.

More than 1200 Fit3D ProScanners are currently operating in 45 countries. Sales from direct selling and distributors have doubled from 2016 to 2017. The company is on-track to exceed 100 per cent sales growth in 2018. (SV)

Fibre2Fashion News Desk – India

Popular News

Leave your Comments

Editor’s Pick

Therese Premler-Andersson

Textile Machinery Association of Sweden (TMAS)

Pratik Gadia

The Yarn Bazaar - Filosha Infotech Private Limited

-Ltd..jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)