Hong Kong's Top Form International selects Coats Digital's GSDCost

As estimates and historical data rely heavily on materials, styles, machinery and people, which change over time, the data being used by Top Form quickly became inaccurate and obsolete, and costs were derived from guesswork rather than fact-based data, which directly affected Top Form’s efficiency calculation, capacity calculation, line balancing, labour and garment costing, and ultimately business profitability.

“It was an easy decision for us to choose GSDCost given that it is the only globally acknowledged time-cost manufacturing standard for the garment industry,” said APD Prabath, group head of industrial engineering for Top Form Brassier Mfg. Co. Ltd. “GSDCost will help us to precisely and accurately establish manufacturing standards, which will be used as a foundation for the correct standard method and time, as well as supporting realistic and sustainable production targets for our operators.”

By implementing GSDCost, Top Form will be able to ensure garments are designed and developed at the right price point, thereby optimising margin, while ensuring fair labour costs are accurately reflected, thus benefiting both the business and its workers. GSDCost’s scientific manufacturing method analysis process, through the application of motion codes with Predetermined Time Standards (PTS), will help Top Form to accurately and consistently establish ‘Standard Time’ throughout its factories, Coats Digital said in its press release.

"GSDCost is an effective tool to engineer the garment cost as all the manufacturing data is based on stringent, fact-based data points,” added Prabath. “It will help us to avoid over/under costing our garments and enable us to make informed business decisions to drive a sustainable and more profitable business.”

GSDCost’s scientific and fact-based approach to calculating the standard time will help the Top Form team standardise every step of each operation to create an accurate method database which will further help in better planning, balanced production lines and improved quality. The Top Form team will also utilise GSDCost’s method standards and advanced methodologies to reduce the ‘Standard Time’ of each operation in the production line and boost productivity even further.

The introduction of a fact-based, scientific approach in this critical area of the business will eliminate guesswork and subjectivity in garment costing and optimise the costing process to avoid over or under costing, thereby improving business profitability.

“We are proud to be working with Top Form International and supporting the business in ensuring that it remains flexible, resilient and strong while being innovative and forward looking," concluded Stephen Dodgson, sales director of Coats Digital for South East Asia. "The adoption of best practice and digitisation of key processes will play a key part in this journey, and GSDCost will support the business in establishing and optimising sustainable manufacturing methods and times, supporting accurate garment costing and improving productivity.”

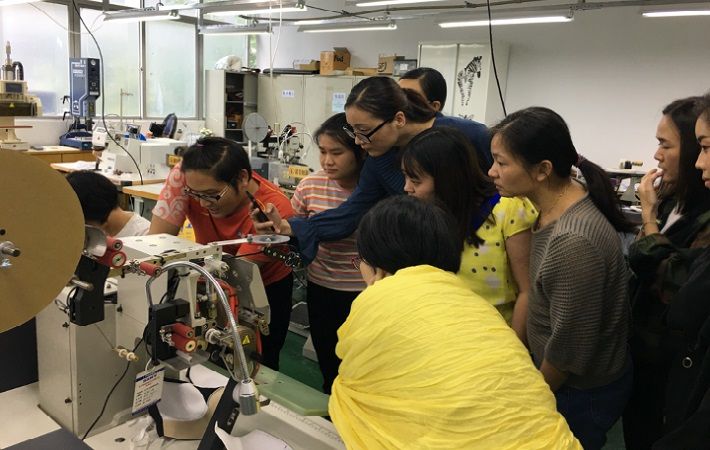

Phase-1 of the GSDCost training was conducted onsite at Top Form’s Product Development and R&D Centre where the team was guided through the various levels and applications of the GSDCost Predetermined Time Standard (PTS) system. The programme included a detailed analysis of the system and practical visualisation exercises, carefully structured to aid the team in the interpretation of the GSDCost codes, the release added.

This was followed by the GSDCost software training where the participants were guided through the software user interface and features, combining the GSD methodology with the speed and depth of the GSDCost solution.

The newly licensed GSD practitioners were then taken to the production floor where, under guidance, they applied their newly acquired skills in a working environment using a core style. They were quickly able to adopt the new software given the logical and user-friendly interface.

Fibre2Fashion News Desk (RR)

-Ltd..jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)