Established in 1982, Reliance Polyester has grown by leaps and bounds to become the world's largest integrated manufacturer of polyester fibre and yarn; apart from continuing to be the bedrock, on which Reliance Industries Limited stands. Commissioning 10,000 tonnes back in 1982, Reliance Polyester today has reached a 2.5 million tonne mark. It is growing at a remarkable pace, thanks to Greenfield investment and acquisitions in the entire value chain.

Today RIL has more than 4% global market share in polyester fibre and yarn. With a presence in major international markets like the U.S., Turkey, Belgium, Denmark, Germany, France, China, Vietnam, Italy, United Kingdom and Indonesia, it spans across 100 plus global markets. A large factor that contributes to the success and rapid expansion at Reliance Polyester is its unique strength of complete integration in the polyester value chain, starting right from crude oil to final products. It guarantees reliable supply and consistent quality as the raw materials (PX, PTA and MEG) are manufactured in-house.

On the ground, Reliance has taken its consumer oriented marketing a step further by clubbing the entire portfolio of all polyester products under one common business, known as the Polyester sector. This constitutes of the staple fibre and filament yarn business, which comes under the brand name of Recron®, and PET, which comes under the name of Relpet®.

Recron® Green

The impact of climate change is being felt all over the world, and so is the need to change our attitude towards the environment. This has resulted in a growing demand for environment-friendly green products which will boost sustainability. Recycling is one of the vital processes in Green Technology concept. It reduces the consumption of fresh raw materials, energy usage, air pollution, and water pollution (from landfilling) and also reduces load on "conventional" waste disposal and lower greenhouse gas emissions.

Recron® Green is a result of processing post-consumer waste into new products to prevent wastage of potentially useful materials and resources. Reliance has developed its own technology to convert post-consumer PET bottles into a high quality polyester staple fibre and tow having the properties nearly identical to the fibre produced from virgin PET polymer. Recron® Green's primary purpose is to decrease dependence on natural resources and increase sustainability. At the same time, it also delivers the same quality that customers have grown to expect from any Reliance product. Not only does Recron® Green deliver the benefits of polyester fibre to as many people and as many uses as possible, it also does so without compromising on any of the parameters that polyester fibre is judged by.

The main advantages from the sustainability perspective are:

The major applications are:

Recron® 3S - New generation synthetic fibre for asbestos replacement

Reliance Industries Ltd. has always encouraged the use of environment-friendly products. Continuing with such endeavours, it has engineered a new generation synthetic fibre for asbestos replacement. This fibre substitutes asbestos used in the construction industry, mainly in roofing sheets and in other construction related applications.

Value Proposition

Asbestos is carcinogenic in nature and so is the reinforcement agent used in asbestos sheets - Chrysotile type of asbestos fibre, (composed mainly of magnesium and silica). Mining of asbestos is banned in India but its usage is not. Hence the industry depends on 100 per cent imports. However, with most shipping lines not accepting asbestos importing firms have to maintain around four months' inventory of asbestos to maintain production.

Asbestos is carcinogenic in nature and so is the reinforcement agent used in asbestos sheets - Chrysotile type of asbestos fibre, (composed mainly of magnesium and silica). Mining of asbestos is banned in India but its usage is not. Hence the industry depends on 100 per cent imports. However, with most shipping lines not accepting asbestos importing firms have to maintain around four months' inventory of asbestos to maintain production.

The new engineered fibre has been launched with the vision of making the world asbestos-free

The fibre is doubly advantageous, as it is both cost-effective and environment-friendly. While asbestos needs to be milled before use, the new-generation fibre has been customised for asbestos sheets manufacturers and hence can be straight away added in the mix tank. The fibre has excellent dispersion and affinity with cement - like materials. These properties result in an increase in flexural strength and durability of the end product.

Such an effective value proposition facilitates a hugely beneficial mutual relationship between RIL and asbestos users and sheet manufacturers in both domestic and world markets.

There is a dedicated team for this venture and efforts are on-going with leading asbestos cement sheet manufacturing companies to achieve 100 per cent replacement of asbestos across the world.

Recron® Feel Fresh

In a hot and humid country like India, most of us yearn for a sweat-free and odour-free feeling and need clothes which are as fresh as spring. So undoubtedly textiles that inhibit the effects of sweat - bacterial growth, related smell and infestation of microbes in the fabric leading to faded colour and performance are the need of the day.

"Recron® has found the solution to this - SILVER. Since days of yore, silver has been acknowledged as an anti-microbial element capable of preventing and even killing many types of bacteria and fungi. That is why our ancestors preferred to be served food on silver platters or even put silver coins in stored water. Hence Reliance's R&D team came up with Recron® Feel Fresh that has silver ions in it. This helps products made from Recron® Feel Fresh staple fibres have permanent antimicrobial and antifungal properties."

The process by which the product works is:

The main advantages of Recron® feel fresh are:

The major applications are:

Quality Certifications:

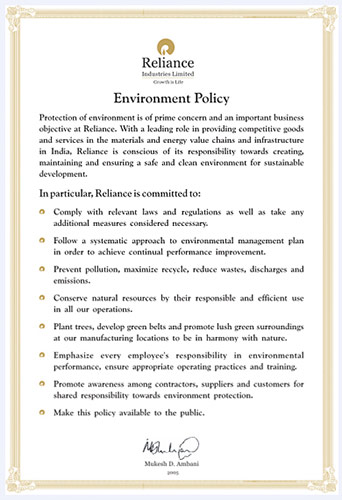

Reliance endeavours for excellence in environmental management and strives towards sustainable business development. Reliance continues to be committed to develop and implement Environmental Management System (EMS) throughout the Group to measure, control and reduce environmental impact. The international environmental accreditation based management system covers all its manufacturing divisions. In a majority of cases this has been integrated with ISO: 9001:2008 Quality Management System and ISO-18001:2007 OSHA management systems.

Reliance endeavours for excellence in environmental management and strives towards sustainable business development. Reliance continues to be committed to develop and implement Environmental Management System (EMS) throughout the Group to measure, control and reduce environmental impact. The international environmental accreditation based management system covers all its manufacturing divisions. In a majority of cases this has been integrated with ISO: 9001:2008 Quality Management System and ISO-18001:2007 OSHA management systems.

RIL is fully compliant with various environmental protection and health and safety laws and regulations. In its constant endeavour to be fully compliant with all regulatory standards, RIL has instituted a compliance management system, which ensures that the Company is in full compliance to all applicable legal requirements. Prior to the implementation of new projects the potential environmental impacts are assessed. The environment impact assessment and risk analysis are performed for all new and major expansion projects and necessary measures are incorporated to mitigate adverse environmental impacts at the planning stage of project.

In line with global best-practices, RIL reports its externally verified environmental performance based on Global Reporting Initiative guidelines. It achieved continuous reductions in emissions and discharges and an increase in effluent and waste recycling.

Reliance Industries Limited

Address: Reliance Corporate Park,

Bldg, No.8, 1st Floor, B Wing,

Thane - Balapur Road, Ghansoli,

Navi Mumbai - 400701,

India

Phone: +91- 22- 44770000

Website: www.ril.com