Maximize your media exposure with our single PR package

Karl Mayer launches Textile-circuit for making e-textiles

30 Jan 19 2 min read

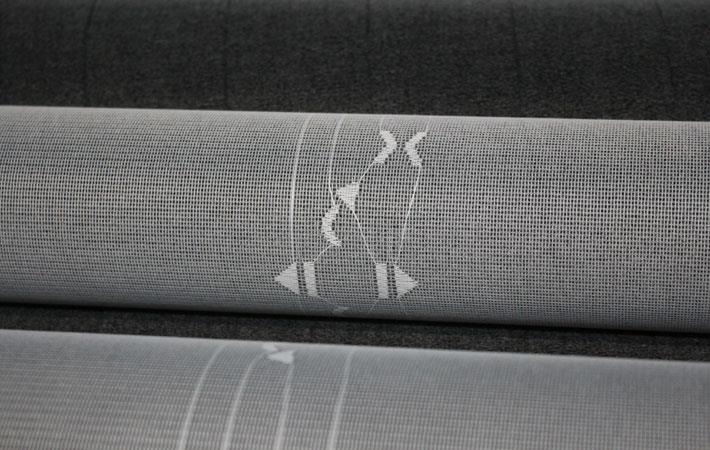

Courtesy: Karl Mayer

Germany’s Karl Mayer, has launched a new project named ‘Textile-circuit’ that works on established warp knitting technology to produce highly innovative e-textiles. Textiles can be used for heating, cooling, and lighting. They can measure the heart rate, and can be launched into space for use as space reflectors, as long as they are electrically conductive.

The electrical conductivity of warp-knitted textiles is the subject of extensive development work at Karl Mayer. In this project, multibar raschel machines are used with and without a jacquard facility to incorporate conductive yarns directly into the textile during manufacture. The first results are now available and show what can be achieved, including the use of textiles for remote control, according to Karl Mayer.

Electrically conductive structures with a virtually unlimited range of designs can be produced on multibar raschel machines. This is possible, thanks to multibar patterning using Karl Mayer’s innovative string bar system, with which the yarns can be positioned individually and as required onto a ground – following the principles of tailored fibre placement. The ground can be produced with a wide variety of different designs, and jacquard patterns can also be worked, depending on the type of machine.

Along with extensive design freedom, warp knitting also delivers maximum efficiency when producing electrically conductive textiles. Furthermore, the typical performance features of textiles, such as softness, flexibility, elasticity and breathability, are fully retained.

At the functional heart of these innovative e-warp-knitted textiles are filaments containing metal, such as Elitex. According to Sophia Krinner, a textile product developer at Karl Mayer, silver-plated polyamide can be processed very easily on multibar raschel machines. Her aim in the next few stages is to optimise the sequences on the machine to suit mass production. (GK) Disclaimer - All News/Articles items are subject to copyright and no article either in full or part may be reproduced in any form without permission from Fibre2Fashion Pvt. Ltd.

Disclaimer - All News/Articles items are subject to copyright and no article either in full or part may be reproduced in any form without permission from Fibre2Fashion Pvt. Ltd.

The electrical conductivity of warp-knitted textiles is the subject of extensive development work at Karl Mayer. In this project, multibar raschel machines are used with and without a jacquard facility to incorporate conductive yarns directly into the textile during manufacture. The first results are now available and show what can be achieved, including the use of textiles for remote control, according to Karl Mayer.

Electrically conductive structures with a virtually unlimited range of designs can be produced on multibar raschel machines. This is possible, thanks to multibar patterning using Karl Mayer’s innovative string bar system, with which the yarns can be positioned individually and as required onto a ground – following the principles of tailored fibre placement. The ground can be produced with a wide variety of different designs, and jacquard patterns can also be worked, depending on the type of machine.

Along with extensive design freedom, warp knitting also delivers maximum efficiency when producing electrically conductive textiles. Furthermore, the typical performance features of textiles, such as softness, flexibility, elasticity and breathability, are fully retained.

At the functional heart of these innovative e-warp-knitted textiles are filaments containing metal, such as Elitex. According to Sophia Krinner, a textile product developer at Karl Mayer, silver-plated polyamide can be processed very easily on multibar raschel machines. Her aim in the next few stages is to optimise the sequences on the machine to suit mass production. (GK)

Fibre2Fashion News Desk – India