Computers and textiles have become an important part of everyday life, say B Deepti Reddy, Ayodya Kavitha and Dr J Hayayadana.

Once upon a time, and for centuries thereafter, computers did not have anything to do with textile production, especially handlooms. This was the era before computers developed and in the early decades of their existence. With increase in demand for textiles, use of computers in textile production has reduced time and effort taken to produce fabric and increased production. Technological developments have helped qualitative and quantitative changes in textiles.

Computers are used for their speed, power and versatility. They facilitate quick computations and precise solutions, saving time. A set of instructions and procedures address the task to be performed, speeding up production and avoiding slower manual work.

Computers are widely used in various departments of the textile industry.

User-friendly operating systems in spinning:

Most operations are controlled through user-friendly operating systems, such as push buttons, electronic screens and electronic stop motions. Electronic screens provide data such as number of bales plucked during a single passage, length of sliver in carding, controls of the machine to be conveyed to another worker and length and diameter of the yarn. Push buttons provide easy access to control the machine. Electronic stop motions stop the machine during any breakage, reducing losses.Touch screens are the most recent trend in operating these machines.

Fig 1: Electronic screen on a carding machine showing sliver properties

To analyse design and prepare peg plan

Using a programme, one can develop a peg plan or card cutting plan providing pattern and loom specifications. This saves time and effort. Software creates the card cutting plan by clicking pictures of an object or a person.

Fig 2: Computerised jacquard card punching machine

Computerised jacquard loom

Unlike older punch jacquard looms, electronic looms use computer generated files that lift threads to make a pattern entered into a computer. Each pixel represents one thread. The computer translates the design into instructions for the loom. A black dot lifts a warp thread or no hole is punched. White spaces represent warp threads to be left down or punch a hole. Electronic jacquard looms use computer-generated point papers to control the loom. This file is the source for modern card punching equipment.

Fig 3: Computerised jacquard

Computerised knitting machine

Modern knitting machines knit a whole garment without cutting or sewing. Some designs may require partial stitching. Software converts the design into a code which the computer understands. The code is fed through a chip and the mechanisms are shown on an electronic screen so that the machine can communicate with the operator. The whole process, from casting on to casting off, to shaping and making many different types of stitches, is automated. The gauge and needle butts follow the path according to the instructions from the software to create the design. This allows faster knitting and higher productivity.

Fig 4: Computerised knitting machine

Testing

Computers are principally used in testing to record and compute values. To record, values are transferred via analogue to digital form and displayed on the screen. Instruments like AFIS and HVI have this facility and error-free results are processed at a fast rate. These machines compute collected data and provide results of the test. They also store data and print it. The process is automated and can be repeated.

Fig 5: Report showing test results for yarn count

In wet processing

Some mistakes were inevitable during wet processing. They could not be recognised or tested by humans. So, computers were brought in.

-

Spectrophotometer: checks the shade of the dyed fabric

-

Datacolour: for formation of accurate dye types

-

Buffer Calculator: calculates amount of alkali/acid for the required buffer

-

Fastnesss properties: computers check the fastness properties

In printing, computers develop the designs and prepare screens which need accuracy like galvano and liquor screens. Digitised printing is the most happening segment in the vertical. Inkjet printing on fabric is also possible with an inkjet printer by using fabric sheets with removable paper backing.

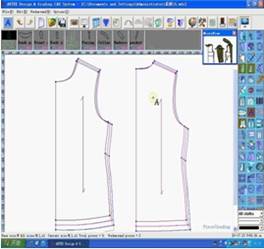

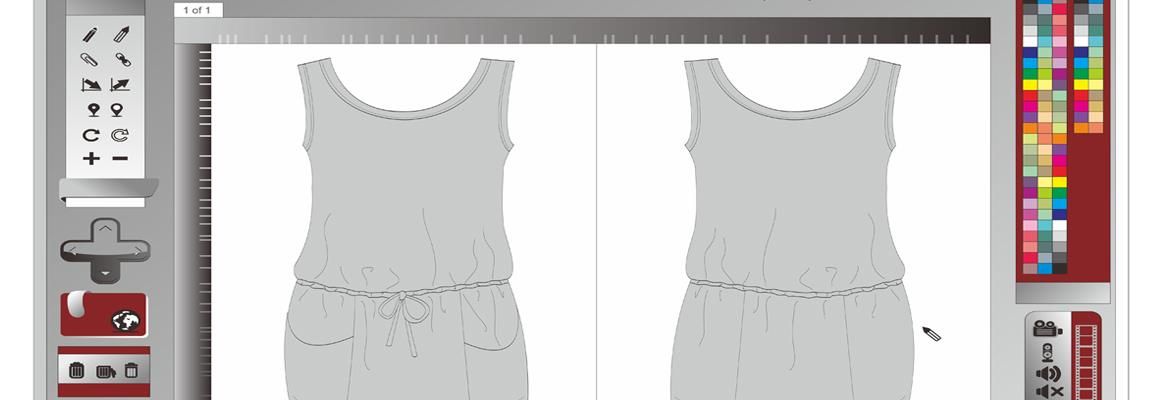

Creating patterns

CAD/CAM technology is finding wide acceptance because of its immense use in design and development of textile machinery. CAD/CAM technology allows the user to design a product or a part of the product or even alter the product. The product can be viewed in 2D or 3D format. Parts of the machine like cams, tappets and the making of blue prints of the machines or parts of the machine. The efficiency and result of the altered part could also be tested in the software itself. Computers are also used to create the patterns for apparel and alter them with software like Richpeace and Tukatech .

Fig 6: Pattern making software

Fig 7: Designing a machine part using CAM

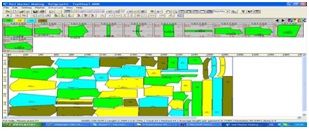

Making markers

A marker is a long, thin paper which contains of all necessary pattern pieces of different sizes of a particular garment. The pattern pieces should be arranged in such a way that there should be less fabric wastage. These patterns are arranged in various ways in the marker making software. The direction and position of pattern pieces could be rearranged a number of times, which is a tedious process if paper is used. The sizes can also be altered easily on a computer.

Fig 8: Marker planning software

Logo embroidery machine

Most embroidery machines in the garment sector are controlled by computers. They work according to the pre-processing programmes given by the user. The instructions can be given through a USB or the machine can be connected directly to the system. The computer controls different motors which move the needle bar up and down and side by side, tensioning discs, feed dog and other elements in the machine.

In single needle embroidery machines, the user changes thread colour. In multi-needle embroidery machines, the machine trims and changes thread colour according to programmed instructions. Popular software includes Bernina, Wilcom DecoStudio E3, and Embird Embroidery Studio Digitizing Software.

Fig 9: Six-headed logo embroidery machine

Software that repeats patterns on home textiles for apparel

In home textiles, we often see patterns repeated. These patterns are placed at the required position using the software and then printed on the fabric. The positioning is exact, using grid lines. The design could be flipped horizontally, vertically or diagonally or repeated, since software offers flexibility. Software like Illustrator, Photoshop, Firework and Genue (for ipod) create and repeat patterns.

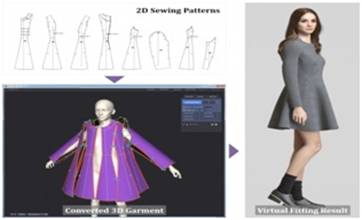

Designing children's clothes with a 3-dimensional parametric dress form

Infant garments cost more than adult garments because extra care is taken during their production as the patterns are small and seams should not be uncomfortable for the baby. So, it is necessary to give the manufacturer every minute detail such as stitch length, type of stitch, direction of stitch and patterning. For that, 3D patterns allow every part of the garment to be clearly visible and production is smooth.

Fig 10: Conversion of 2D pattern to 3D Apparel

Evolving IT trends for mass customisation in apparel industry

Through E-commerce, products are reaching customers easily. Textiles are the top selling category in the E-commerce sector. Not only garments, even textile machinery is sold online. Even handloom products are available at the doorstep, unlike the previous scenario where the customer had to purchase the product at the manufacturing area. Success of sites like Jabong, Myntra and Snapdeal has encouraged India's leading textile manufacturer Arvind Ltd to start its own e-commerce site, Arvind Internet Ltd.

Cloud computing in textiles

Cloud computing or Internet-based computing provides data sharing to computers and other devices on demand. This has replaced the need to carry stacks of papers and files which could then be misplaced. Large files are transferred within minutes. The order quantity information, the CAD/CAM files, machinery guides, production planning files, raw material management and supply chain management are easily shared. However, cloud computing runs the risk of hacking, data loss and lack of control.

Fig 11 Computers are used in process cycle management and Enterprise Resource Planning (ERP)

The industry needs to keep up with developing technology. In the last few decades, many developments like automation in spinning, weaving and garmenting have taken place in the textile sector. The Information Technology (IT) revolution made things easier and faster. Using computers, the textile sector reached new heights. Computers are, in fact, the pointer to a more promising future.

About the authors:

1. Ayodya Kavitha is an assistant professor in the department of Textile Technology from the University college of Technology-Osmania University. She has completed her MTech and PhD in textile technology. She has even done her MBA in Human Resource Management along with SET in management.

2. B.Deepthi Reddy is pursuing her in Textile Technology from the University College of Technology, Osmania University.

3. Dr.J.Hayavadana is a Professor and head of the department of Textile Technology in the University college of Technology-Osmania University.

Reference:

1) Computers and Automation in Weaving; Southeast University School of Science & Engineering, Department of Textile Engineering, Md. Fazley Elahi Assistant Professor Southeast University Dept. of Textile Engineering

Slideshare.net

2) Computerized Loom Expands Oppurtunities; Matt Campbell; Kansas City Star; 29 Feb 2012

3) Texlnfo.wordpress.com

4) Textilelearner.blogspot.in

5) Application of Computer in Wet Processing; Fardous Wahid Anik, Department of Textile Engineering, Ahsanullah University of Science & Technology (AUST), Bangladesh.

6) Application of CAD/CAM in the Textile Industry; PB Jhala; Machinery Design Division, ATIRA, Ahmedabad, India (1991)

7) Application of CAD/CAM in the Textile Industry. Dwivedi S.N., Verma A.K., Sneckenberger J.E. (eds) CAD/CAM Robotics and Factories of the Future '90. Springer, Berlin, Heidelberg

8) Wikipedia.org

9) Seasonedhomemaker.com

10) Edutechwiki.unige.ch

11) Fibre2fashion.com

12) Textile-firms try self-run e-commerce platforms to build on consumer loyalty; Vinay Umarii; Ahmedabad; 26 August 2014, Business Standard

13) Cloud Computing for Managing Apparel and Garment Supply Chains- an Empirical study of Implementation Frame Work; Prof. A.K. Damodaram, Department of Mechanical Engineering, Sree Vidyanikethan Engineering College and Prof. K. Ravindranath, Department of Mechanical Engineering, S.V. University College of Engineering

14) IJCSI International Journal of Computer Science Issues, Vol. 7, Issue 6, November, ijcsi.org

Images courtesy:

1. Sco1.alicdn.com

2. Ad-borgner.com

3. Texabc.com

4. I.ytimg.com

5. Meship.com

6. Vetigraph.com

7. Creative-textiles.com

8. S2015.siggraph.org

9. Media.licdn.com

10. Accentureacademy.com

Comments