This article states the severe impacts of textile industry on the environment and their possible solutions.

The textile industry is one of the primary contributors to environmental pollution from past few years. With time people have apparently become more aware about the environment issues arising out of the pollution created by the textile industry. Textile industry also needs to be amended in terms of raw materials used, production techniques, services and after life to mitigate the negative repercussions on the climate.

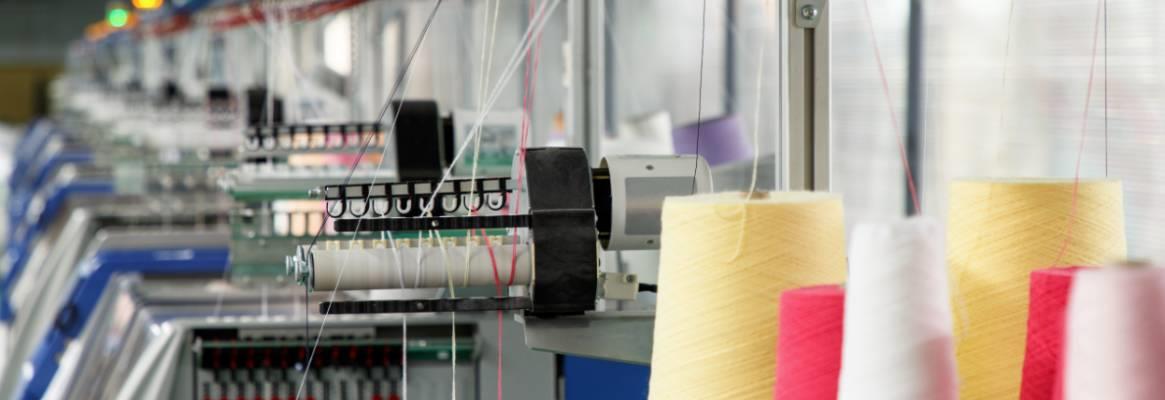

Various innovations have been done to alleviate the impact of textile manufacturing by use of sustainable raw materials, waterless dyeing, closed loop production and circular fashion. Garment production consists of myriad diverse steps from fibre to textile alteration i.e spinning, weaving, knitting, preparatory wet processes, dyeing and/or printing, finishing, assem-bling and packaging. In this whole cycle, apparel is treated with various chemicals that are highly toxic in nature. Each operation leads to an increasing consumption of energy and water.

There are various avenues to alleviate the environmental impacts caused by textile manufacturing industries as follows:

•Sustainable raw materials: Raw material is responsible for adversely impacting the environment to a large extent. Cotton production demands enormous amount of land, water, fertilisers whereas silk leads to the depletion of natural sources and global warming. On the other hand, man-made fibres such as polyester is non-biodegradable. Therefore, in order to diminish the impact of tex-tile and apparel production processes, some alternatives have been developed such as - hemp, stinging nettle fibre, coffee ground fibre, pineapple fibre, banana fibre, orange fibre and lotus fi-bre, etc. Beyond this, consumers need to be enlightened about sustainability, campaigns can be done in stores or through tags on clothes. It may be possible to educate consumers to buy only what they need and to pick more sustainable options.

•Waterless dyeing: Waterless dyeing is the procedure of dyeing textiles without the use of water and less energy than conventional techniques of dyeing yet achieving impressive colours in solids and prints. It needs less process, time, chemicals, and auxiliaries.

•Closed loop production: Closed loop production cycle includes designing, production, usage and handling of a product. Here the product circulates in the society for as long as possible. It also in-cludes reuse of material waste created during the production process of additional products as well as use of recycled products to create new items.

•Circular fashion: Circular fashion is the process of focusing on waste reduction rather than the linear concept of take-make-waste. When clothes are no longer in use, they can either be sold as seconds or recycled and for this the product should be made in such a way that it can offer mul-tiple life cycles.

•4 R’s (Reuse, Reduce, Repair and Resale): About 90 per cent of textiles that are discarded by the consumer can be recycled and technology has made this a lot easier.

Repairing a distorted garment will increase its life.

Re-selling or donating clothes after one has used it. These small steps will help us to achieve sustainable fashion. Greenhouse gas emissions would be lowered to a great extent on the condition that number of times that a garment worn is increased.

•Slow fashion: Slow fashion, is a concept of "slow movement” which supports the manufacturing with respect to people, environment and animals. It is more of based upon quality rather than time and encourages slower production, small batch collections, zero waste, unifies sustainability with ethics which results in attracting consumer to invest in well made and long-lasting clothes and make a capsule wardrobe.

•Automated manufacturing: Automation is the use of computers to control the process which reduces human interference and thereby increases the product quality. It also opens the possibil-ity of producing locally and reduces the transportation cycle that in result reduces pollution, and also diminishes the need of offshoring. Few examples are sewbots, 3D printing, fully automated manufacturing plants, etc.

Conclusion:

lants and animal lives. Therefore, it is absolutely necessary to use eco-friendly processes that beget less pollution, less waste, require less resources and are simpler to ad-minister.

About the author: Achala Jaglan is a student studying in the Technological Institute of Textiles & Sciences, Haryana and K N Chatterjee is a professor from Netaji Subhas University and Technolo-gy, New Delhi.

Comments