Interviews

News Flash

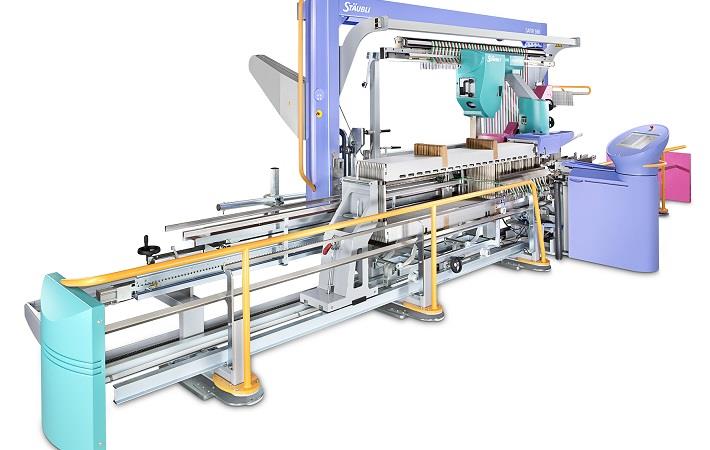

Staubli continues to drive Swiss machinery innovation

03 Dec '20

3 min read

Pic: Staubli

Staubli is determined to meet the current challenge posed by the pandemic by providing flexible and reliable solutions for long-term use and by driving innovation to provide modern and market-oriented solutions for Swiss textile industry. Staubli, a member of Swissmem since January 1897, was among the founders of textile machinery division of Swissmem.

Goals of the textile machinery division were to secure supplies of raw materials, develop international relations, to approach markets in a united and effective way, and to continue making high-quality products in Switzerland and selling them throughout Europe and the rest of the world, even during difficult times. The division has been globally promoting Swiss textile machinery in recent years with the slogan ‘Innovation: it’s in our DNA’.

At Staubli, innovation gene dates back to 1892 and is evident today in the 500-some R&D engineers working to invent, redesign or improve Staubli mecatronics solutions. Forward-looking and continuing to innovate during the present time in which people and businesses everywhere are struggling with a global crisis, are the intrinsic values of Staubli.

In their united quest for excellence, the various Staubli teams bundle their expertise, long-term business experience, and the input of sales and technical teams who collaborate closely with customers and thus learn the real needs of the weaving mills and the markets. This rich combination results in a diversified product portfolio that meets the requirements of any woven application and covers the needs of any weaving company.

Staubli sets worldwide standards in the weaving industry. Prime examples are active warp control (AWC) and initial condition settings (ICS), applied in the company’s Safir automatic drawing-in machines. AWC enables automatic supervision and management of yarn types and colours during automatic drawing in. ICS represents state-of-the-art technology for efficient style and warp changes, enabling easy start-up after style change with specific yarns, such as hairy or technical yarns. These and other leading-edge technologies help to optimise the process flow within the mill and greatly enhance operational performance.

In the Jacquard weaving sector, Staubli is the leading provider of weaving equipment for airbag and large-format weaving. The LX/LXL/LXXL Jacquard machines are available in many formats, with up to 25,600 hooks, and formats of up to 51,200 hooks can be achieved by combining two machines.

December 9, 2020 will mark the 80th anniversary date of the Swissmem textile machinery division. The Swissmem textile machinery division will celebrate its next future milestone in 2030, at which time we will certainly look back on 2020, a year that will mark history books due to the pandemic which has devastated individuals and businesses around the world. To face this crisis, mankind has been called upon to adapt and remain flexible, and businesses have been challenged to innovate.

Fibre2Fashion News Desk (JL)

Popular News

Leave your Comments

Editor’s Pick

Yohan Lawrence

Joint Apparel Association Forum (JAAFSL)

Folker Stachetzki

Brother Internationale Industriemaschinen GmbH

Susanne Guldager

Label - La Femme Rousse

-Ltd..jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)