Interviews

News Flash

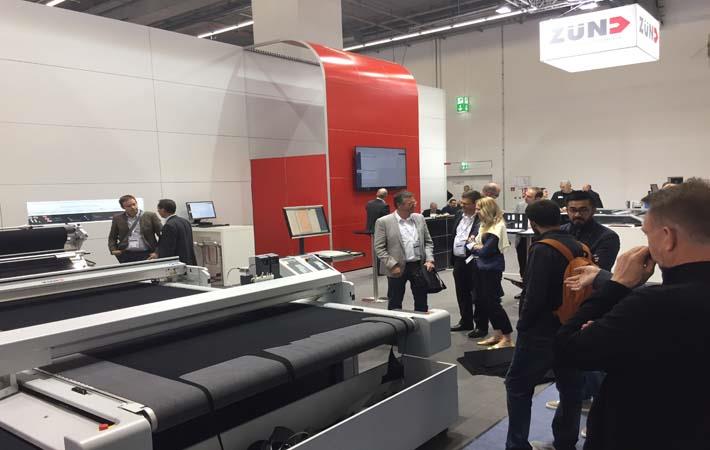

Zund shows latest textile solutions at Texprocess 2017

23 May '17

2 min read

Zund, the leading provider of digital cutting systems from Switzerland, presented its latest solutions for highly productive and flexible textile cutting, at the recently held Texprocess 2017 expo, leading international trade fair for the international garment-manufacturing and textile processing industry, held from May 9 to 12, 2017, in Frankfurt, Germany.

How to improve productivity through higher-performance equipment, better workflow integration, and more flexibility in processing cutting jobs, were the primary topics of conversation with many prospective and existing customers and partners. Thus, many visitors to the Zünd booth were equally interested in Zünd’s digital cutting systems and the latest solutions for automatic roll handling and advancing. This is why Zünd took the opportunity to introduce the new cradle feeder at this year’s Texprocess. The new material-handling system permits unwinding/advancing and rewinding high-stretch fabrics completely without tension. Equipped with integrated edge control, the cradle feeder ensures precise placement of the material on the cutting surface and is even capable of error-free advancing less than perfectly wound materials, including telescoping or coreless rolls.

With the D3 cutter, Zünd also showed off its most productive cutting system, capable of unprecedented performance because of its innovative dual-beam design. The two beams, each equipped with up to three different modules or tools, operate simultaneously and independently. Depending on the specifics of the cutting jobs and designs, this can up to double the throughput of the system, which is a significant advantage in a market dominated by the need for ever-shorter times to market. Because of Zünd’s insistence on modularity, the D3 cutting system is no exception when it comes to its adaptability to changing requirements. New tools, modules, or automated material-loading/unloading systems can easily be integrated and added to existing installations.

A Zünd cutter was also part of the Digital Textile Micro Factory and provided fashion producers and garment manufacturers a hands-on demonstration of the ways they can benefit from a high- performance Zünd cutting system – particularly with its remarkable ability to reduce time to market. The workflow concept that Zünd introduced in cooperation with several partners, is titled “Simulate, Print & Cut”. Besides digital design and pattern development, the concept also includes 3D visualisation. (GK)

How to improve productivity through higher-performance equipment, better workflow integration, and more flexibility in processing cutting jobs, were the primary topics of conversation with many prospective and existing customers and partners. Thus, many visitors to the Zünd booth were equally interested in Zünd’s digital cutting systems and the latest solutions for automatic roll handling and advancing. This is why Zünd took the opportunity to introduce the new cradle feeder at this year’s Texprocess. The new material-handling system permits unwinding/advancing and rewinding high-stretch fabrics completely without tension. Equipped with integrated edge control, the cradle feeder ensures precise placement of the material on the cutting surface and is even capable of error-free advancing less than perfectly wound materials, including telescoping or coreless rolls.

With the D3 cutter, Zünd also showed off its most productive cutting system, capable of unprecedented performance because of its innovative dual-beam design. The two beams, each equipped with up to three different modules or tools, operate simultaneously and independently. Depending on the specifics of the cutting jobs and designs, this can up to double the throughput of the system, which is a significant advantage in a market dominated by the need for ever-shorter times to market. Because of Zünd’s insistence on modularity, the D3 cutting system is no exception when it comes to its adaptability to changing requirements. New tools, modules, or automated material-loading/unloading systems can easily be integrated and added to existing installations.

A Zünd cutter was also part of the Digital Textile Micro Factory and provided fashion producers and garment manufacturers a hands-on demonstration of the ways they can benefit from a high- performance Zünd cutting system – particularly with its remarkable ability to reduce time to market. The workflow concept that Zünd introduced in cooperation with several partners, is titled “Simulate, Print & Cut”. Besides digital design and pattern development, the concept also includes 3D visualisation. (GK)

Fibre2Fashion News Desk – India

Popular News

Leave your Comments

Editor’s Pick

-Ltd..jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)