Festo has announced that over 2,200 components from its product range named Stars in Automation are available for delivery worldwide. The company has doubled its production capacities worldwide over the last two years. The focus of these efforts has been on expanding the Festo core product range in the field of pneumatic and electric automation products.

These Stars in Automation include over 2,200 components from every phase of the pneumatic and electrical control chain, from compressed air preparation, valves and cylinders to accessories, such as matching tubing and fittings. With the Festo core product range, machine and system builders can realise around 80 per cent of all applications quickly, effortlessly, and at attractive prices, even when large quantities are needed, according to Festo.Festo has announced that over 2,200 components from its product range named Stars in Automation are available for delivery worldwide. The company has doubled its production capacities worldwide over the last two years. The focus of these efforts has been on expanding the Festo core product range in the field of pneumatic and electric automation products.#

Many of the components marked with the star are ready to be shipped just 24 hours after the order is received, while configurable products are ready for delivery within five days. All products in the core product range are available worldwide and with the same level of quality thanks to automated production at various decentralised locations in the core markets of Germany, China, and the US. There are further plants in India, Brazil, Hungary, the Czech Republic, Bulgaria, and Switzerland.

Distribution is also decentralised thanks to highly automated logistics centres in Germany, China, and the US, so 70 per cent of all customers can be reached within one day.

The hallmark of the latest components of the core product range is the collaboration between the design engineers and production planners at Festo. They worked closely together during the development of these products to ensure that the Festo plants can manufacture the components with a high degree of automation. For example, Festo engineers manufactured the yoke and slide for the new mini slide. DGST as a single part in order to enable large quantities to be produced efficiently. The developers successfully reduced the number of components by 60 per cent compared with the previous model.

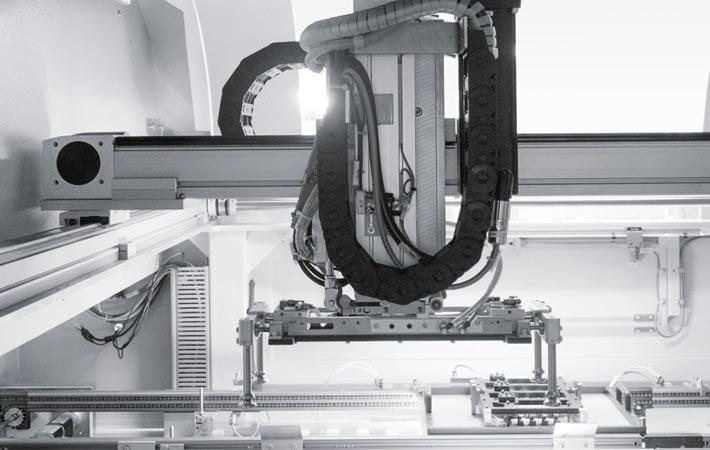

This simultaneous engineering approach allowed Festo to reduce cycle times by almost 50 per cent for the DGST or the guided drive DFM. Festo plants can now produce a DFM every minute, for example. Another example is the fully automated production line for the standard valve VUVG, which produces a fully assembled valve every 12 seconds.

The paths between the individual production steps are shortened and throughput times are reduced thanks to new organisational methods. These include aligning production and assembly with value streams and the consistent application of Operational Excellence (OPEX) methods, such as Lean Management or Six Sigma. Festo also intends to use these new methods to increase efficiency and productivity at its production, assembly and logistics locations over the coming years.

The accelerated product development process has paved the way for the latest Stars in Automation. The mini slide DGST, for example, is the smallest of its kind and the shortest slide drive on the market.

Other new Stars in Automation include the lightweight compact cylinder ADN-S, which is produced almost entirely as one part and can perform small and micro-movements in the smallest of spaces. The regulators and filter regulators of the MS2 series service units are designed for use close to the process directly in the machine and for end-of-arm applications. They are lightweight and compact, but with high flow rates of up to 350 l/min. (GK)

Fibre2Fashion News Desk – India