Color Service’s systems are designed to deal with problems that arise from manual dosing in the following ways—eliminating over- or under-use of chemicals by accurately weighing the chemicals, the error of picking the wrong chemicals, and the wastage of chemicals in manual transfer with automatic transfer of chemicals. Moreover, no safety margins are required for recipes; the average recipe amount can be reduced, Color Services said in a press release.

Color Service’s range of products includes automatic dosing and dissolving systems for powder dyestuff, liquid chemicals, and powder dyes (in production and laboratory) for dyeing and printing houses. It includes automation for powder dyes TRS, automatic for powder dyes – dye dissolver and weighing SCC, automation for liquids – DLV series, and automation of powder chemicals DAP.

With the ability to weigh as little as 0.01 g of dyestuff, TRS is the most accurate weighing system available in the market today. A patented scraper ensures that dyestuff is dispensed as very fine particles which ensures control. Long lasting aluminium silos prevent sticking of dye powder due to static electricity. Blocks of silos can be chosen with volumes from 90 to 450 L depending on the dye consumption. It is possible to add or replace them with different capacities depending on future requirements.

Color Service also provides semi-automatic storage and weighing systems for powder dyes. PESMAN is a PC-controlled scale, which guides the operator to weigh the correct quantity of dye. It is integrated with a label printer and barcode reader to avoid mistakes in picking the dyestuff.

PATERNOSTOR is an automatic dosing system for dyeing production that is designed to save space in the dye kitchen. All dye boxes are stored vertically, enabling space savings. MAGROB is an advanced version of PATERNOSTOR. A robot assists the operator in handling the boxes of dyes.

The SCC is a machine designed to automatically dissolve and weigh powder dyes. It is considered the fastest in the market, with the ability to deliver a bucket of dissolved dyes every six minutes. Unlike other machines that use a stirrer or mixer, the SCC uses three-dimensional circulation to dissolve dyes much faster. This method also makes cleaning after dissolution much easier. The SCC can automatically add dispersant agents or acetic acid for disperse or acid-based dyes. Additionally, it can adjust the mix of hot and cold water according to the dye stuff being dissolved to ensure the right temperature for dissolution. The SCC has a bucket washing station that uses two buckets, one for washing and one for dissolving, thereby reducing idle time. Overall, the SCC is an efficient and time-saving solution for dye dissolving and weighing.

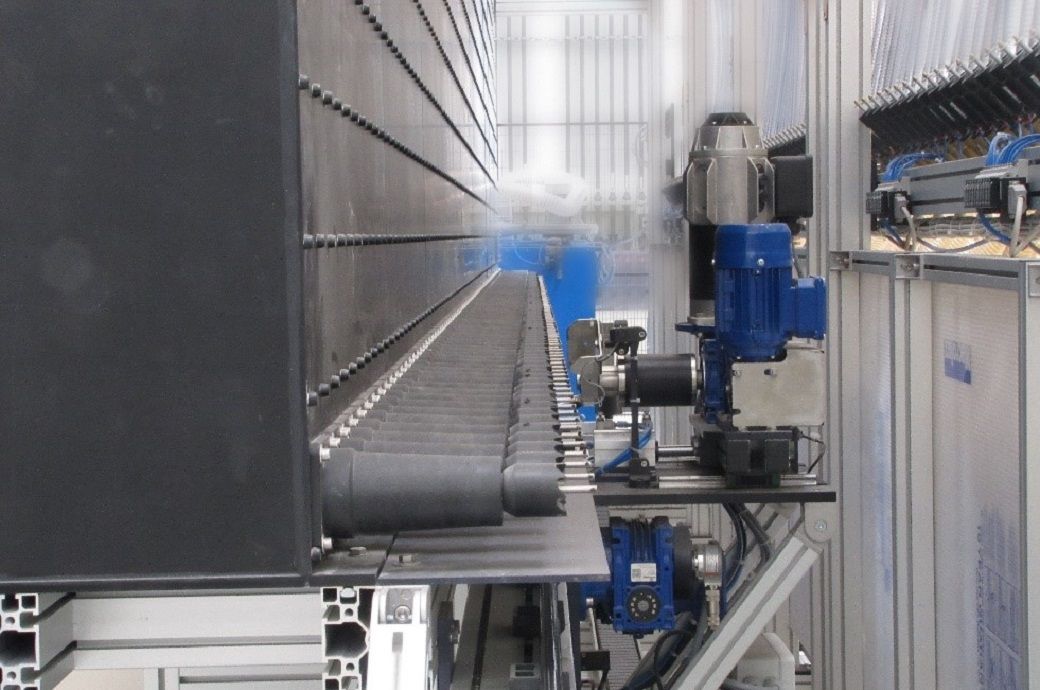

The DLV series is a versatile solution for the dispensing of liquid chemicals in dyeing production. It boasts a modular structure that enables easy addition of more inlets for liquids or outlets to the dispenser, giving users the flexibility to start with fewer liquids and add more as needed. Compared to flow metres, the system’s use of load cells guarantees better accuracy (with a margin of error of less than 0.1 g) for dispensed amounts below 500 g. Additionally, the DLV series can deliver materials to two destinations simultaneously, increasing dispensing speed by up to 70 per cent, saving space and reducing costs in the factory. The DLV series can work with both monoline and multiline technologies. Color Service utilises air blow technology to transport liquids to usage points, reducing water consumption and increasing the life of distribution valves in the monoline system. The DLV series is equipped with a mass flow metre that guarantees high accuracy (+0.1 g). It is best suited for dispensing optical brightening agents (OBAs) or liquid dyes as the built-in load cell technology ensures accurate and separate dispensing of these materials from other liquids.

The DAP is a versatile product designed for dissolving powder chemicals up to a concentration of 1:1. It can be combined with a range of silo capacities, ranging from 450 to 3100 L, and these silos are made of fibreglass and come equipped with level sensors and vibration units. The loading of powder is done using vacuum, and the operator only needs to drop the bag of powder into the hopper. From there, the material is transferred into the silos using vacuum. The DAP is suitable for use with both mono-line and multi-line dispensing technologies.

Color Service offers automatic dispensing systems that provide numerous benefits. One of the advantages is their 24/7 operation, ensuring uninterrupted production. The systems are fast, reliable, and can guarantee constant uniformity on the batch, eliminating any chances of mistakes or human error. The uniformity of the operations and superior quality further improve the chances of high-quality standards and customer satisfaction. Additionally, traceability is ensured with all report data captured and recorded on management system software, making traceability or quality certification issues easy to handle.

Operator safety is also considered, as the automation of many manual activities significantly reduces the chances of inhalation of hazardous powders, toxic dust, and carcinogenic chemicals. This also saves worker time, allowing them to focus on more crucial duties, leading to better workforce efficiency and saving time and money. The dispensing systems also reduce the wastage of chemicals by up to 10 per cent, promoting zero waste. Moreover, the automation process helps to decrease carbon footprint, save energy and materials, and reduce waste, leading to a healthier environment.

Lastly, with these benefits, medium-scale companies can also upgrade themselves in a phased manner by starting with automation for liquids. By implementing Color Service’s automatic dispensing systems, customers’ quality and competitiveness are dramatically increased due to the accurate dosing of raw materials complying with high-quality standards.

Fibre2Fashion News Desk (NB)