Interviews

News Flash

BRÜCKNER presents revolutionary dryer technology at ITMA

26 Jul '11

5 min read

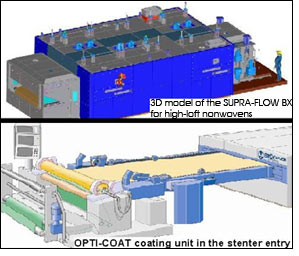

SUPRA-FLOW BX - the high-loft expert

This new dryer is used for the bonding of high-loft nonwovens. Nonwovens with a weight of up to 6000 g/m² and an initial thickness of 300 mm can be finished. The flow in the dryer can take place from the bottom up or from the top down, depending on the process and the fabric type. Also in this case the advantages of the countered design are apparent. The homogeneous air and temperature distribution across the complete fabric length and width ensure a high-quality end product. An optimum air control system requires less electrical energy and saves thus costs. The system is very easily accessible for cleaning and maintenance. To convince our customers of the benefits of this system we will have within a short time a pilot plant available for fabric tests.

TECHNO-LINE COATING - innovative line systems for the functionalizing and coating of textiles

BRÜCKNER lines allow among other things direct coating on textile webs and foils, reverse coating on transfer paper, impregnation and submerged coating as well as dry and wet lamination of membranes and textile webs. A particular highlight is a new application unit for the direct coating of bi-elastic knitted fabric which is integrated in the stenter entry. In addition a new application unit for the coating of the lower side of the textile web has been developed. Both units in combination allow a simultaneous coating of the upper and lower side of the textile web in one dryer passage.

Solvent coating units are required for the production of a great variety of technical materials. Glass mesh fabric is for example coated with resins to produce grinding discs. Seat covers are often laminated with coated membranes or foils to ensure the breathability. And also for the production of sailing cloth or artificial leather made of PU a solvent coating application is used. BRÜCKNER lines provide for an intelligent exhaust air system which charges the exhaust air with solvents up to the maximum acceptable limits. Thus, enormous energy savings can be achieved by reducing the exhaust air quantity. A system for the monitoring and control of the exhaust air burden provides for failure-free operation and the meeting of the legal regulations.

We can offer you of course many more novelties and developments, for example our own lubricants for a smooth machine operation or modification and modernization possibilities for your existing lines. We will be glad to explain the benefits for you in a personal discussion. Visit us on our booth in hall 6, stand no. A-113. We are looking forward to meeting you!

This new dryer is used for the bonding of high-loft nonwovens. Nonwovens with a weight of up to 6000 g/m² and an initial thickness of 300 mm can be finished. The flow in the dryer can take place from the bottom up or from the top down, depending on the process and the fabric type. Also in this case the advantages of the countered design are apparent. The homogeneous air and temperature distribution across the complete fabric length and width ensure a high-quality end product. An optimum air control system requires less electrical energy and saves thus costs. The system is very easily accessible for cleaning and maintenance. To convince our customers of the benefits of this system we will have within a short time a pilot plant available for fabric tests.

TECHNO-LINE COATING - innovative line systems for the functionalizing and coating of textiles

BRÜCKNER lines allow among other things direct coating on textile webs and foils, reverse coating on transfer paper, impregnation and submerged coating as well as dry and wet lamination of membranes and textile webs. A particular highlight is a new application unit for the direct coating of bi-elastic knitted fabric which is integrated in the stenter entry. In addition a new application unit for the coating of the lower side of the textile web has been developed. Both units in combination allow a simultaneous coating of the upper and lower side of the textile web in one dryer passage.

Solvent coating units are required for the production of a great variety of technical materials. Glass mesh fabric is for example coated with resins to produce grinding discs. Seat covers are often laminated with coated membranes or foils to ensure the breathability. And also for the production of sailing cloth or artificial leather made of PU a solvent coating application is used. BRÜCKNER lines provide for an intelligent exhaust air system which charges the exhaust air with solvents up to the maximum acceptable limits. Thus, enormous energy savings can be achieved by reducing the exhaust air quantity. A system for the monitoring and control of the exhaust air burden provides for failure-free operation and the meeting of the legal regulations.

We can offer you of course many more novelties and developments, for example our own lubricants for a smooth machine operation or modification and modernization possibilities for your existing lines. We will be glad to explain the benefits for you in a personal discussion. Visit us on our booth in hall 6, stand no. A-113. We are looking forward to meeting you!

Brückner Trockentechnik GmbH & Co. KG

Popular News

Leave your Comments

Editor’s Pick

-Ltd..jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)