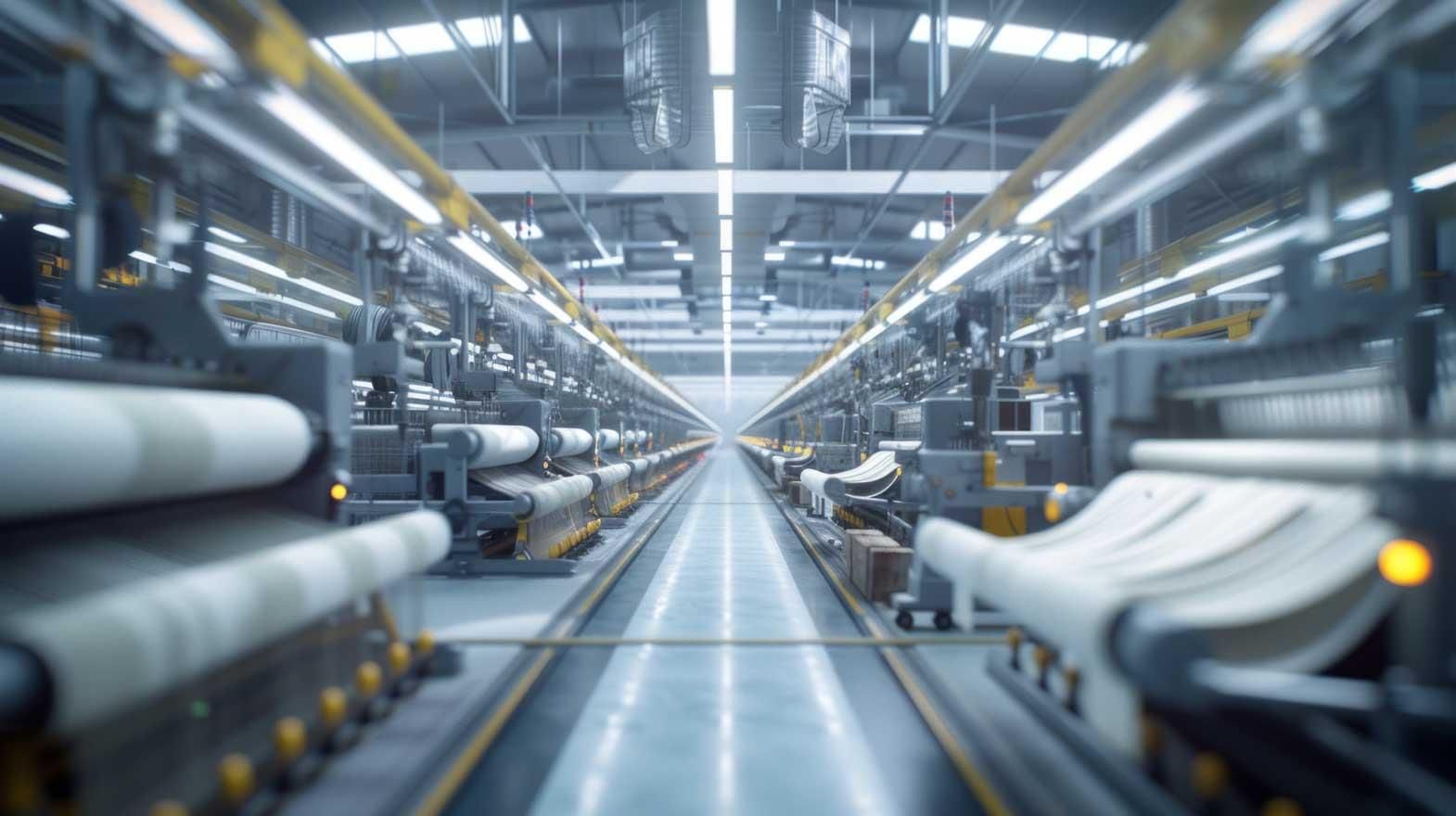

All are aware that spinning is a part of the textile manufacturing process. It is a process where strings of fibers are converted into yarn. Further, the spinning process involves many functions like cotton mixing, carding, combing, drawing, and the last step is winding. In this process, a small amount of yarn is wound into big cones.

However, it is important to maintain the quality in any textile process. The quality of the textile depends on the quality of the yarn. Therefore, it is essential for manufacturers to produce good quality yarn to sustain in the competitive market.

Along with the quality aspect, one should not ignore productivity as it is equally important in the spinning process. Manufacturers must concentrate on both these aspects. In this respect, the manufacturers should see that methods adopted to improve the quality of the yarn do not affect the productivity. There are different spinning techniques and machines developed for each technique.

Ring spinning is considered as the most trustworthy, cost-effective, and successful yarn manufacturing method. Ring spinning system has gone through many changes in the past 30 years. This spinning technique has improved continuously in the past years with its goal on higher production, along with speed and superior quality. The quality of yarn produced by this technique is considered to be the best and is accepted worldwide.

It is broadly used because of its high speed and the quality of yarn it produces. This technology produces yarns which are structurally stronger. It produces softer yarns and fabrics. It can be used to spin any material. Its operational functions are very simple to learn and understand. Moreover, as the speed in the drawing section can be properly managed, the uniformity of the yarn is very well maintained.

Another new invention in spinning is the vortex spinning technology. It is one of the most promising technologies in recent times. In this method, with the help of air jets, false twist is developed. The chief advantage of the vortex spinning machine is that it has the ability to spin carded cotton fibres at a phenomenal speed of 400m/min. Furthermore, the cost of maintenance is low as there are fewer moving parts.

The older roving frame process is removed and a fully automatic piecing system has been established. Moreover, yarn produced with this technique is less hairy compared to the normal ring spinning machines. In addition, the fabrics made from these yarns have exceptional qualities like resistance to scratch, absorbs moisture, has color fastness, and dries quickly.

The spinning machines are continuously being developed to achieve the main goals of spinning. Such as high productivity, low maintenance cost, and best quality yarn. The new air jet spinning machine has been developed recently with high performance theory. This air jet machine has achieved the targeted spinning speed of 450m/min compared to the normal delivery speed of the ring spinning machine which is 15-27m/min.

The rotor spinning machine and air jet spinning machine are almost similar in construction. However, this new air jet machine has four robots to do the functions like changing the bobbin, arrangement of yarn piecing, and cleaning. Also, it has the provision to simultaneously produce two different qualities of yarn without getting mixed up. The robots are highly reliable. Any faults or problems are sorted out without waiting for manual instruction.

The quality of cotton yarns produced in Poland was not good compared to the yarns produced in countries like India, Turkey and China. This had posed a big challenge to the Polish manufacturers as these yarns had already entered the Polish textile market. To improve the quality of their yarns, the local manufacturers purchased new machines.

These machines included carding machines, combing machines, cleaning machines and latest spinning frames. Today, the polish yarns are at par or even better than the imported yarns. Their effort to improve the quality of the yarn by using new types of spinning machines and techniques has yielded them positive results.

Rotor or open end spinning has been established since 1960s and the technology has grown over these years. The new automatic rotor spinning machine provides many additional benefits that the older machines did not have. The new machine is set to produce better, softer and more yarns. Its intrinsic features will further increase the speed and improve efficiency at the same time will consume less energy.

This machine has become very successful as it produces superior quality yarn. The buyers have accepted it as its benefits are clearly visible. It is easy to operate and very reliable. Moreover, its elements can be replaced without using the tools. Further, its new structure prevents fibre accumulation or changing the spinning conditions and has very low hairiness. The 'cool nozzle technology' keeps the surface cool.

All these features result into higher productivity with different types of synthetic fibres. The manufacturers have already experienced the benefits of the new spinning technology with better yarn strength and evenness.

The new age spinning technology has widely caught the interest of the manufacturers around the globe. The high speed rotor spinning machine is giving tough competition to other machines in the market. Innovative spinning techniques have tremendously changed the performance of different types of spinning machines. The benefits of the improved machines are not limited to producing high quality yarns or increase in productivity but have completely changed the scenario of the spinning sector.

References:

1. Cottonyarnmarket.net

2. Indiantextilejournal.com

3. Slideshare.net

4. Cottonyarnmarket.net

5. Evolution.skf.com

20240830145908.gif)

Comments