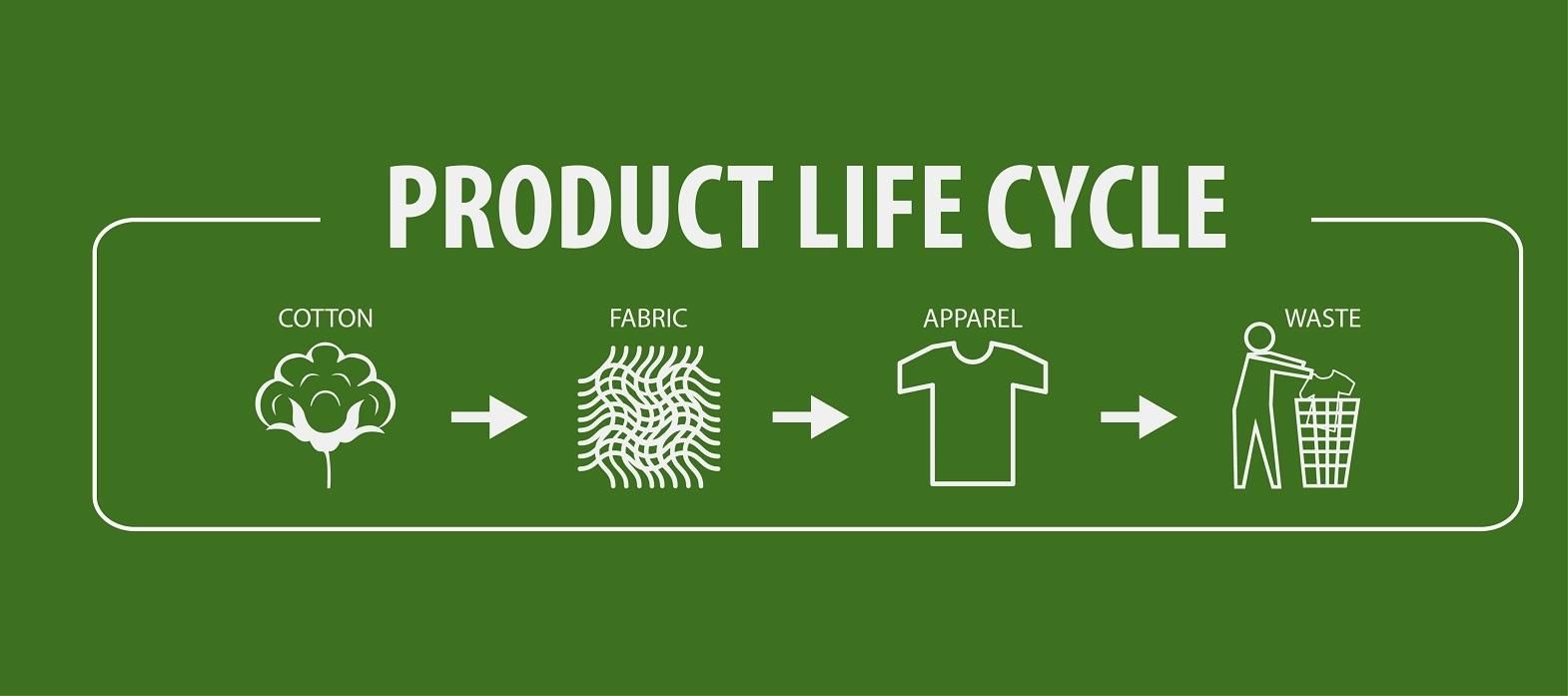

The fashion sector experiences major and minor transitions daily, making the application of Product Lifecycle Management (PLM) a valuable approach for apparel manufacturers. PLM ensures more efficient production while considering environmental concerns.

Today, fashion trends change frequently, with numerous seasons displaying the latest styles. The simple act of manufacturing trendy designs can lead to significant errors. In the past, these errors were considered part of the cost of doing business. However, retailers and manufacturers have recognized that PLM can help eliminate these errors, leading to its widespread adoption. According to vendors, PLM software can reduce a product's lifecycle management time from an average of 120 days to approximately 60 days.

Emerging markets have increasingly relied on PLM systems as American and European markets have matured. In countries like China, where the fashion industry historically did not heavily rely on information technology, recent financial crises have changed this stance. Today, the textile and apparel industry in China recognizes the importance of technology in later stages of business operations.

The use of PLM has significantly optimized overall production, resulting in cost reduction. PLM is now more commonly used in the textile sector in Brazil. Other countries such as India, Sri Lanka, and some African nations view PLM systems as a necessity rather than a luxury. However, even as PLM usage increases in developing nations, it remains largely confined to large-scale textile production facilities.

According to a report from the Brazilian Service of Support for Micro and Small Enterprises (SEBRAE), the adoption of PLM systems is still limited because most textile industries focus on introducing and improving technology at the basic level of production. Post-production application of technology requires additional capital, which is challenging for these industries to secure.

The growth of the retail sector in developing nations has compelled some high-end brands to recognize the efficiency that PLM systems bring in terms of accuracy, profit, and innovation. However, smaller retailing and production houses often employ line managers to gather essential information, unaware that PLM systems can perform the same tasks more accurately without requiring monthly payments.

PLM is influenced chiefly by the fast fashion. The retailers must be equipped to adapt quickly to constant changes. The important trends that affect PLM include labour cost, fast fashion, energy costs and green momentum. Today the rising cost of labour means that units depend more on technology rather than workforce. The chances of error are reduced with technology and also the companies save good amount on labour. PLM also assists in product development, wherein, the manufacturers can enjoy the ease of taking the decisions close to in-store delivery.

PLM has made it easier to evaluate what's selling and what's not, thus avoiding excessive inventory of an outdated product. PLM also assists in evaluating the end-retail stores that are nearer to the manufacturing units, thus saving the energy costs on fuel and transportation. Also, today, for eco-friendly retailers and brands green priorities are intensifying the scrutiny of the sourcing process. PLM is a strong tool to handle the product development process and the sourcing process simultaneously.

There have been improvements in the PLM, but almost all the developing nations have to import PLM systems from countries like United States, Germany, France, etc., as most of the developing nations are not yet self-sufficient, as far as technology goes. There are companies that create PLM specifically for fashion sector, following specific requirements concerning the apparel and fashion industry, which cannot be fulfilled by PLM designed for other sectors like traditional automotive and aerospace industries.

It is the level of speed that fashion industry needs is a lot more than the conventional PLM, as the fashion industry needs to create designs for Spring, Summer, Fall and Winter. The major research and development with regard to PLM is carried out in developed nations. Therefore, the PLM systems that the developing nations import are often not the updated versions in most of the cases.

PLM is required to ensure that the companies work as per the global need of production and to shorten the time required for the post production processes like taking stock of inventory. This enables overall growth, increased profits and gives the companies spare time for creative ideas. These factors often decide the fate of organisations and open up the chances to locate, manage and document work related to environmental and social responsibility.

The benefits of PLM definitely outrank the initial investment that the companies require, as it gets a good riddance from the losses by reducing the errors. The PLM's future in fashion industry is fairly robust with around 63 percent of apparel companies saying they plan to further invest in PLM technology in coming years.

References:

1. Itcinfotech.com

2. Ptc.com

3. Just-style.com

4. Technia.com

20240830145908.gif)

Comments