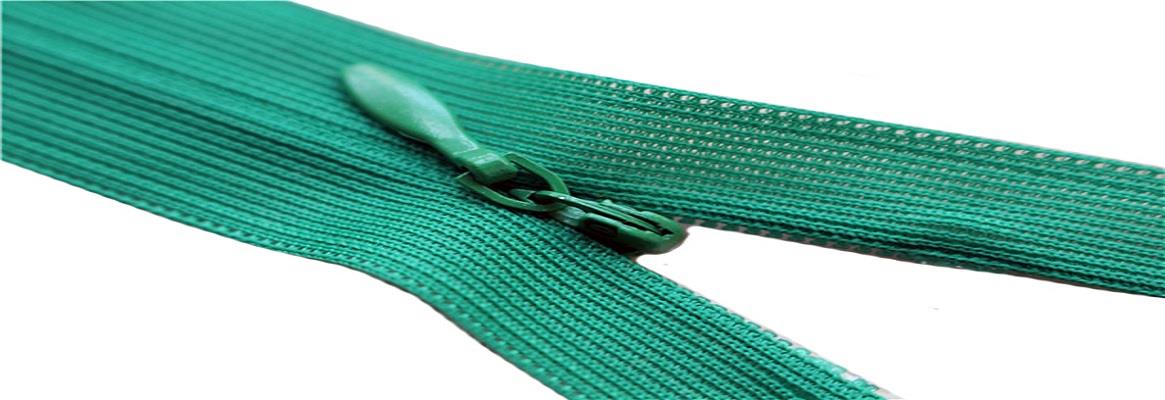

Every garment has a story to tell. From fabric to accessories, every detail leaves a lasting impression on the prospective customers. Expectedly, while delivering the final product to the end user, it is important to pay attention to garment accessories like zippers that can either lift or ruin the garment.

Dyeing is one of the most crucial aspects of textile manufacturing process that offers character to the garment, but can also affect the way a zipper works and appears. Unlike the conventional dyeing method that involves prior dyeing of yarn or fabric, and then using the dyed fabric to make garments, garment dyeing colours the final product like jackets, skirts, scarves, et al. Garment dyeing can achieve extraordinary and unique effects on the fabric that cannot be attained through conventional dyeing processes. The trouble with garment dyeing technique is that a petty error can ruin zipper and the final product thereof.

Though, various garment dyeing techniques like tie-dyeing, dip-dyeing, pigment dyeing, over dyeing, reverse dyeing, etc. are all different from each other, what binds them is the use of chemicals in the dyes. If the manufacturers ignore using dye-friendly zippers, it can wreak havoc on the finished garment. The inappropriate use of techniques and chemicals involved in garment dyeing can damage zippers in more than one way.

-

The chemicals in dye can result in colour change of the metal components of the zipper. When metal parts like the slider, top stop, bottom stop and other open parts of a zipper make contact with different kinds of chemicals, it may cause discolouration of those parts and the fabrics.

-

Continuous heating and soaking can damage the hem of open ended zips, thus making it peel off.

-

Heat and chemicals can also damage the teeth of zipper and result in shrinkage of the zipper.

The good news is that paying heed to the garment dyeing process can make a zipper's hard life a little easier. Below are some tips you could follow when using sbs zips.

1. The nature and concentration of dyestuff or chemical must always be kept in mind to ensure that a zipper stays perfect. Some dyes react when they come in contact with copper alloys. This chemical reaction results in a change of colour. When a reactive dye is used, garment should be rinsed off thoroughly to counterbalance the pH from chemicals. Emphasis should be laid on properly rinsing the zipper and the surrounding fabric so that the colour remains intact.

2. If the garment comes with a brass zipper then application of reactive dyes must be avoided completely. Reactive dyes are safe for moulded plastic zippers and coil zippers.

3. Often the colour change is accelerated if zipper remains pressed against wet fabric or the garment itself is stored in a high humid environment. It should be ensured that the garments are completely dried after rinsing.

4. The safest bet, however, is to do a pre-production test on a few garments to avoid any undesirable outcome that can damage the zipper.

References:

1. Sbs-zipper.com

2. Amann.pl

3. Textilelearner.blogspot.com

Comments