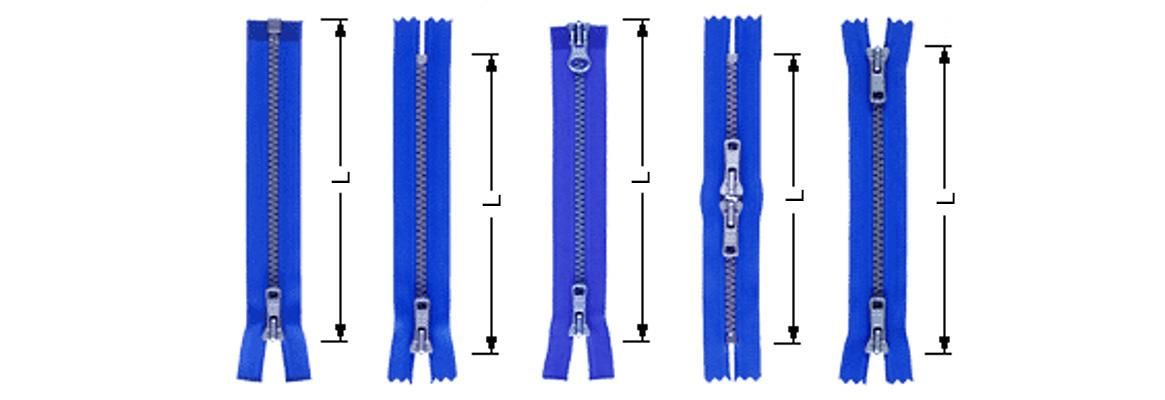

The length of zips varies, depending upon their types. We will discuss about proper methods for measuring the length of different types of zips through this article, including open ended zips and closed ended zips

All zips must be completely closed prior to measuring them, no matter what types they fall into.

Open Ended Zips

They are the ones whose both halves can be fully opened at the end, where one side of the zip can be completely separated from the other side. The length of such open ended zip can be measured from the top end of its zip slider to the tip of its open end. The forth head tape is excluded here. If the forth head tape is considered while measuring the length of the zip by mistake then you would get a zip with shorter length.

Closed Ended Zips

They are the ones whose both halves cannot be opened at the end or both the ends of the zip cannot be completely separated from one another. Such kind of closed ended zip can be measured from the top end of its zip slider to the tip of its bottom stopper. Both forth head tape as well as back head tape are excluded here. If the forth head tape or back head tape is measured by mistake while taking the length of the zip then you would get a zip with much shorter length.

2 Way Open Ended Zips

The length of such kind of 2 way open ended zip can be measured from the top end of its zip slider to the bottom end of its reinforced tape then to the tip of its open end. The forth head tape is excluded here.

2 Way Closed Ended Zips

They are available in O and X shapes and both of them include 2 zip sliders. The main difference while measuring their length are:

1. O shape has 2 bottom stoppers with its sliders arranged in head-to-head relation. Its length can be measured from the tip of one bottom stopper to that of the other one. Both forth head tape as well as back head tape are excluded here.

2. X shape has 2 top stoppers with its sliders arranged in bottom-to-bottom relation. Its length can be measured from the top end of one zip slider to that of the other one. Both forth head tape as well as back head tape are excluded here.

Allowable Tolerance

Zips usually showcase natural tolerance because of some of the factors such as techniques and operational speed of the machines as well as tensility of the zip chain involved while manufacturing them. This tolerance is often proportional to the length of the zip. Additionally, the allowable tolerance applied also differs from country to country.

Reference:

1. SBS Zipper

Comments