Yarn spinning is the process of manufacturing yarn from different types of fibres into a continuous length from one or more type of fibres, writes Pradeep Kulshrestha.

Spinning is the most important and the initial step in fabric manufacturing. The major task of spinning is to produce a variety yarn from raw material, then remove the process faults followed by winding the short length bobbins on cones. There are different types of spinning; the most common forms are: ring, rotor, air jet, friction, etc.

Construction of textile yarns

Yarn count, yarn ply and yarn construction interrelate to form the characteristics of yarn. Yarn construction is classified as:

Conventional yarn: These are two or more simple single yarns plied or twisted together. They are referred to as two, three, four, five or six ply yarn. Size and number of plies may be changed for different weaves or fabric structures.

Complex/novelty yarns: These are single or plied yarn structures characterised by internationally introduced irregularities in size and twist effects. The irregularities of novelty yarns may be uniform or random.

Metallic yarns: A monofilament flat yarn produced by lacquering aluminium pigment or by laminating aluminium foil between layers of plastic. After this webs are cut into wide coils and the rolls are slit into fine ribbon-like yarn. After slitting, the yarn is wound onto spools or coils depending on type of ribbon. Since metallic yarns are flat rather than round most as most of other man-made fibre yarns, the size of the yarn is specified in inches.

Textured yarns: Textured yarns are the end result of physical, chemical or thermal manipulation of fibres and yarns so that they are no longer straight or uniform. The manipulation process of textured yarn results in the modification and altering of the arrangement of the fibres and yarn. Texturising produces a permanent change in the physical structure of the yarn. The fibres no longer lie parallel to the other.

Bulked/high bulked/lofted yarns: High bulk yarns are created and processed by nonlinearity or loop formation in individual filaments. The process introduces crimps, loops, curls and crinkles into the yarn. Bulk yarn may also be shrunk and stretched introducing shrink differentials. The resulting yarns of these processes are bulked, fluffed, puffed and twisted yarns.

Stretch yarns: Almost all man-made and natural fibres can be treated to produce yarns with some degree of stretch and recovery. Stretch properties may be applied to yarns by chemical or mechanical methods. Not all methods or fibres will achieve equally effective stretch properties.

Staple yarns

Cut staple manmade fibres arrive in boxes at the mill, and are ready for carding and processing into yarn. When two or more different staple fibres are mixed, it is critical to provide extensive blending before carding and repeated doubling of the sliver to assure intimate blending prior to roving and spinning.

Staple yarn formation involves multiple steps and can include:

-

Fibre cleaning and opening (as needed for natural fibres);

-

Fibre blending (to assure uniform mixing in natural fibres or in fibre blends);

-

Carding ;

-

Combing (if highly aligned fibres are desired);

-

Drawing and spinning (to reduced the denier of the yarn, to provide twist and to give cohesion to the yarn);

-

Doubling or plying and twisting of the yarns (as needed to provide greater uniformity).

Filament spinning systems are much less complex because the fibres are continuous and do not need to be highly twisted to give a cohesive strong yarn.

Yarns can be made of staple fibres by any one of several techniques:

-

Conventional ring spinning;

-

Open-end spinning or rotor spinning;

-

Friction spinning;

-

Self-twist spinning;

-

Electrostatic spinning ;

-

Vortex spinning;

-

Air-jet spinning;

-

Twist-less spinning.

Description of the most popular fancy yarns

Boucle, gimp and loop yarns

-

These yarns are made by feeding one or more effect yarns faster than the core yarn while spinning.

-

Boucle has a hard twisted core yarn; the effect yarn is rapidly twisted round the core so that excess yarn forms an irregular wavy, bumpy surface.

-

Gimp is more or less same as boucle, but the excess yarn forms a more regular surface.

-

Loop yarn is the result of the excess soft spun yarn being formed into well shaped circular loops on the hard spun core.

Snarl yarns

Snarl yarns are made in a similar way to loop yarns except the effect yarn has a high, lively twist, so that the excess bits snarl and double up on themselves and twist together (Just like the lengths of cord we make on a door-knob!)

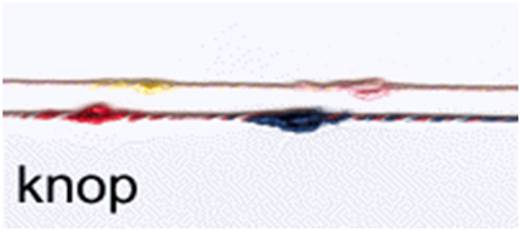

Knop or button yarns

-

These yarns are also made by feeding the yarns at different rates while spinning.

-

But this time the excess yarn of one or more of the components forms bunches.

-

These can be at regular or irregular intervals.

Slub yarn

-

Slub yarn is characterised by having alternating short places of thin firm twist yarn with places of very thick loose twist yarn.

-

The different area can be at regular or irregular intervals.

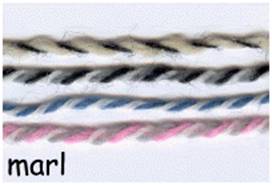

Marl yarns

-

Marl yarns are made by twisting together two or more ends of different coloured yarns.

-

The effect pattern is one of regular diagonal stripes of each colour.

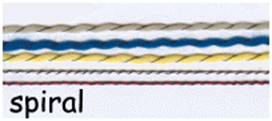

Spiral and corkscrew yarns

-

These are plied yarns where one yarn wraps around the other, rather than the yarns being twisted together.

-

A spiral yarn has a higher twist than a corkscrew yarn.

-

A spiral yarn usually has a thinner yarn wrapped round a thicker core.

-

A corkscrew yarn has a softer bulkier yarn wrapped round a thin, it is firm yarn.

Chenille yarns

-

Chenille yarns have a soft, fuzzy cut pile which is bound to a core.

-

These yarns can be spun, but the machinery required is very specialised.

-

For this reason, these yarns are usually woven on a loom.

-

The effect yarn forms the warp, which is bound by a weft thread.

-

The weft thread is spaced out at a distance of twice the required length of pile.

-

The warp is then cut half way between each weft thread.

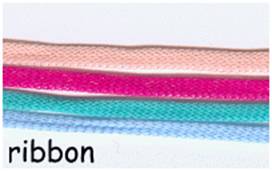

Ribbon yarns

These yarns are not produced by spinning.

They are finely knitted tubes, pressed flat to resemble ribbon or tape.

The ribbons are usually soft, shiny and silky.

Conclusion

The value and characteristic of innovative fancy yarns are determined by

-

Kind and quality of fibre;

-

Amount of processing necessary to produce fineness;

-

Amount of twist which increases strength in the final yarn.

Technical yarns like glass, aramid, carbon, dyneema can be blended in required proportion for composite and cost effective end use.

About the author

Pradeep Kulshrestha has over 30 years of experience in textiles operations management, administering world class manufacturing plants and project implementation. He is currently with Nandan Denim Limited (Chiripal Group), Ahmedabad as DGM - Denim & Shirting.

References

1. Indian Textiles (Comprehensive Forecast) - 2015 by Jay Narayan Vyas

2. Basics of Textiles by Dilip Satashiya

3. Shanghai Henghui International Company Limited, (Mainland), Shanghai

4. Exhibition at ITMA ASIA CITME 2014, Shanghai

5. Teijinarammid.com

6. Reiter.com

7. Dsm.com

20240830145908.gif)

Comments