Functional finishes to surgical fabrics for blood repellency and anti-microbial action boost the protection level for doctors in a hospital, say N Mekala and Dr J Srinivasan.

Sterilised gowns do not offer a permanent solution in hospitals. The sterilisation process must be carried out repeatedly without which microorganisms may harm doctors and paramedics. Functional finishes, applied to cover the inherent weaknesses of cotton and polyester, may be an alternative to overcome this problem. As the comfort level of surgical gowns depends on the fabrics, the fabric variety assumes key importance.

Textile products offer a conducive environment for bacterial growth, which may cause health problems and inconvenience due to odour and fabric disorientation. As microbes often attack the additives applied to the textiles, it leads to discoloration and loss of its functional properties, like elasticity.

In this study, two types of fabric - one pure cotton and the other a 67:33 polyester-cotton (P/C) blend - were selected and dyed with vat (bucket) dyeing process. The dye used for the cotton fabric was jade green 2G, while blue MR was used for the other. For safety, the fabrics were treated with anti-microbial silver and a blood-repellent perfluorocarbon (PFC) coating through pad dry cure method (pad-85 per cent, dry on wet dry/shock cure-140'C/60 min).

The treated samples were evaluated for changes in physical and functional characteristics. Impact penetration test (AATCC 42-2000) and spray test (AATM) were used for assessing the blood repellent finish. Agar diffusion method was used to assess the anti-microbial finish at the incubation chamber in CMS College of Arts and Science, Coimbatore.

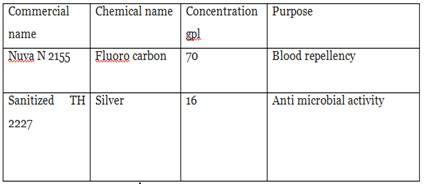

The fabrics were finished with anti-microbial and blood repellent finishes by using chemicals obtained from Clariant Chemicals Pvt Limited in Tiruppur as shown in Table 2.

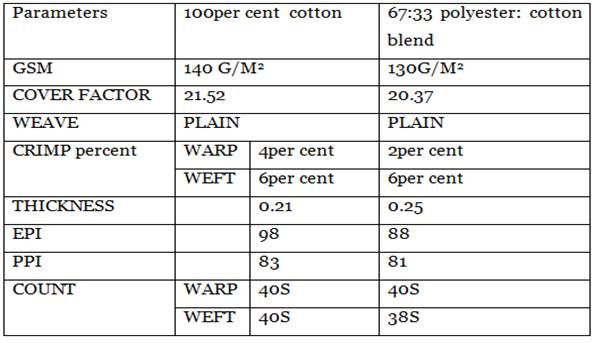

Table 1: Specification of materials

Table 2: Chemicals Used For the Coating

After the finished fabrics were dried at 140�C for about an hour, their efficiency and durability was evaluated. The anti-microbial and liquid repellent properties of the fabrics - both untreated and the ones after the chemical finish - were evaluated as per relevant standards.

Hospitals mostly use cotton and cotton-blended fabrics for gowns. Sterilization is generally used for protection from microbes. For additional safety during surgeries and to reduce infection between doctors and patients, anti-microbial and blood repellent finishes are preferred.

The treated fabrics were tested for their tensile strength, air permeability, blood repellency and anti-microbial activity and were found to fulfill the requirements needed for the hospital gowns. ASTM standards were used to test the physical properties. Pennsylvania-based ASTM International is a global standards organisation that develops and publishes voluntary consensus technical standards for a wide range of materials, products, systems and services.

Tests, such as SEM (scanning electron microscopy) and FTIR (Fourier transform infrared spectroscopy) were used for character analysis.

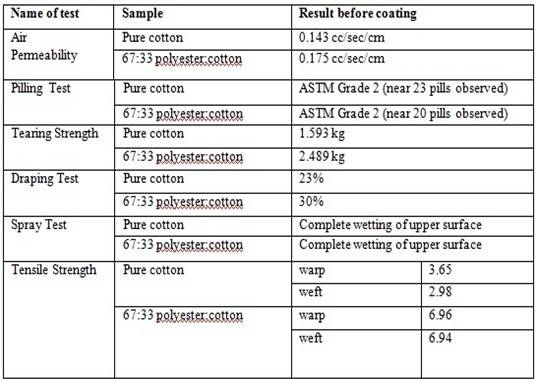

Table 3: The physical properties

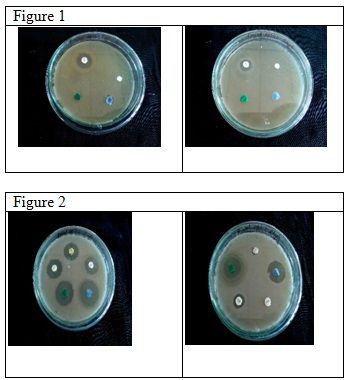

In the images below, one can view the pure cotton and 67:33 polyester: cotton samples before (Figure 1) and after (Figure 2) coating with E. coli and staphylococcus. Anti-microbial activity was observed in both the samples after treatment.

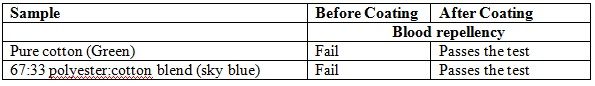

The blood repellency test was done using the ASTM F1670 standard and the durability of the samples after the treatments was also measured.

Table 4: Blood repellency report

Therefore, it was concluded that two additional functional finishes given to surgical fabrics for blood repellency and anti-microbial action can greatly boost the protection level for doctors and paramedical staff in a hospital apart from improving their comfort levels.

About the author

1. N. Mekala is an assistant professor at Bannari Amman Institute of Technology, Sathyamangalam

2. Dr. J. Srinivasan is professor and HOD of the Department of Fashion Technology at Kumaraguru College of Technology, Coimbatore

Comments