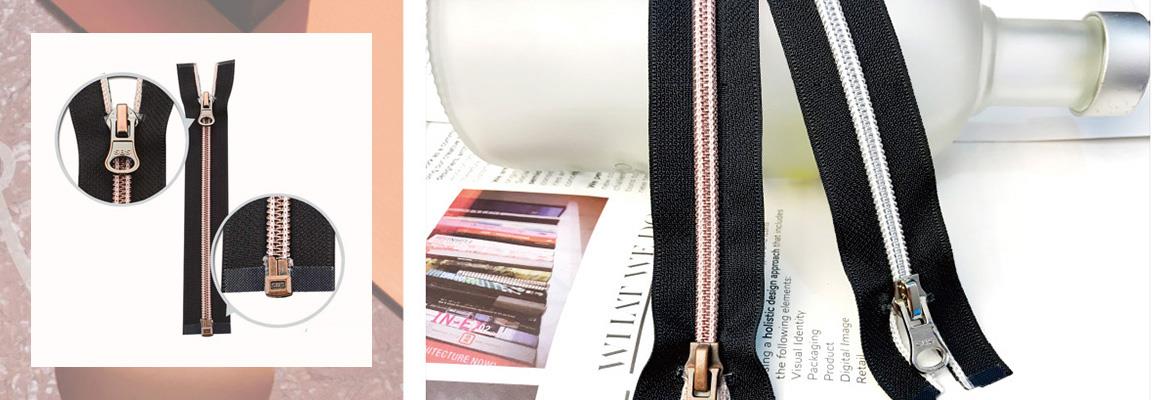

Coating coil zippers are the ones whose teeth are coated with an aluminium layer through vacuum plating. The following guidelines may be followed while using coating coil zippers for their better performance.

1. Colour effect

Coating coil zippers are available in a wide range of colours apart from regular ones like gold, silver and black nickel. Only the front teeth are coloured, neither the back nor the side of the zipper can be coloured.

2. Usage

Used in decorative applications like plackets and pockets, these zippers are popular in the apparel industry and in the production of soft bags. Unless mentioned, double check with the sales persons if the zippers can be used for any other application as well.

3. Slider selection

Choose the sliders that go through electrophoresis or spray painting. Please do not use electroplated sliders as those rigid inner cavity may damage the coating layer and may even lead it to fall off the zipper surface.

4. Special Fabrics

Separate the teeth from the fabric which contains dioctyl phthalate (DOP) to avoid any colour migration taking place between the fabric and the surface of the teeth.

5. Cleaning process

Make sure that cleaning agents like laundry detergents, DJW or any other agents do not come in direct contact with the teeth as that may peel off the colour film from the teeth surface. Besides, in order to protect zippers from oxidation and discolouration, please do not spray the chemical agents directly on the metal accessories while manufacturing the garments or bags.

6. Packaging

Do not package the products unless those are completely dry after being ironed. Breathable plastic bags are good choice to protect coating coil zippers from oxidation, discolouration, corrosion and peeling off.

7. Storage

Please store the products in a dry environment and avoid expose them to direct sunlight for a long time.

20240924091633.png)

Comments