Introduction

Classical denim is a heavy fabric made from 100 per cent cotton and woven from coarse indigo dyed warp and grey undyed weft yarn. It has hard-wearing, high density fabrics with a high mass per unit area and a 3/1 or 2/1 twill weave construction. Denim is available in attractive indigo blue shades and is made for a variety of applications and in a wide range of qualities and shades. Besides indigo blue, denim is also dyed in other fashion shades and colors, the most popular being black. Denim is comfortable, fashionable, affordable and durable and popular in all age groups. It is available in different weight ranges from 6-16 oz/sq yd which is categorised as light denim 10-12 oz/sq yd., heavy denim 14-16 oz/sq. yd.

Excel, a commercial name of lyocell fibre produced by Birla Cellulose of the Aditya Birla Group, is the latest man-made cellulose fibre. The raw material used to make lyocell fibre is wood pulp. This is sourced from harvested trees and is, therefore, a renewable resource.A solvent is used to dissolve the cellulose directly into a very viscous solution. After filtration, the solution is extruded to yield fine filaments, from which the solvent is subsequently removed by washing.

The resulting tow is dried and cut to staple fibre. A key feature of the process is that virtually all of the solvent is recovered and recycled. Thus, the effluent from the process is minimal and most importantly, its not classified as hazardous. Lyocell, as a cellulosic fibre, absorbs moisture and is fully biodegradable. It is characterized by its high strength both dry and wet. It shows a dry tenacity significantly higher than other cellulosics and close to that of polyester.

Lyocell fibre has exceptional attributes like extreme strength, high moisture absorbency, skin- friendliness, excellent lusture and high colour depth, fibrillation and seude effect, unique drape and fluidity, high dimensional stability and wash and wear characteristics.

Due to these attributes, lyocell denims are very popular nowadays and thus bulk manufacturing is rising.

Denim has been used as a clothing material for centuries due to its high durability. But today'sfashion arena likes denim jeans due to its attractive shades, designs, styles and various types of wash appeal, rather than for its robustness. Denim jeans in the past were worn in a raw, rigid and starch-finished form. But today's fashion requires various types of washing treatments, such as desizing, enzymatic washing with or without stones, decolorization, neutralization, brightening and finishing.

Normally denim washing is carried out in sewn garments. The denim jeans are subjected to different washing techniques, such as rinsewash, bleach, enzyme wash, acid wash, stonewash, moonwash, sandwash, sun wash, overdyed/ tinted look, whiskering, damaged and used look. In denim washing, enzymes played an important role to get clean, smooth, fuzz free fabric surface with reduced tendency of pill formation and improved fabric handle.

Raw denim jeans show natural shade of indigo that is faded during wear and subsequent

washes at home. However, in some cases it is believed that raw denim is not practical as it creates some problems of rub-off on other materials that come into contact with it. The unfixed dye on the surface of the fabric may cause stains to other fabrics.

To overcome this problem, denim jeans are washed after sewn. The main plus point of prewashing of denim jeans is that the colour is not transferred to other fabrics or surfaces during wear.

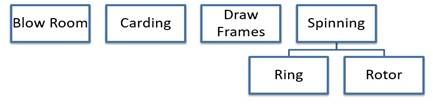

Figure 1: Flowchart for lyocell denim yarn manufacturing

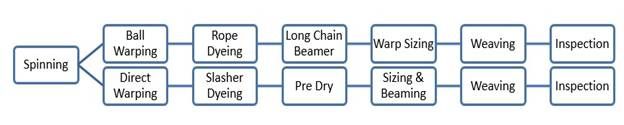

Figure 2: Flowchart for lyocell denim woven fabric manufacturing

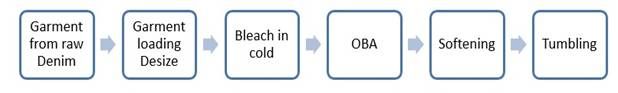

Figure 3: Flowchart for lyocell denim woven fabric finishing

Denim garment wash effects

Traditionally, indigo denim fabric is deep blue in shade. Denim finish may be of two types: as raw and pre-washed. In the first type, the denim is not washed after weaving. Washing treatment on denim garments offers an aesthetic finish, enhances the appeal and increases the fabric strength. Various types of denim washing are available as per requirements. However, each technique has its own advantages and limitations. Denim washing is of two types: chemical and mechanical

Chemical washes

Denim bleaching wash: Denim bleaching treatment discolors the denim garments in specific places and exhibited a unique look to the garments. The degree of severity of the bleaching depends on several factors, such as strength of the bleaching agent, temperature and duration of the treatment. Denim bleaching is normally carried out with a strong oxidative bleaching agent like sodium hypochlorite (KMnO4). Bleaching may be carried out with or without the addition of stone. The bleaching washing effect and de-colouration usually depends on the strength of the bleach liquor, liquor quantity, temperature and treatment time. The bleached fabric materials should be properly antichlored or after-washed with peroxide to reduce the subsequent yellowing or tendering of the bleached denim fabric.

Figure 4: Flowchart for lyocell denim bleaching wash

Hypo bleach: Typical sodium hypochlorite bleaching process for denim is as follows:

-

The bath material to liquor ratio is set at 10:1 and temperature at 60oC

-

0.5% (on weight of garments) of soda ash is added

-

20-30 g/l of 12% sodium hypochlorite is added

-

Bleaching is carried out for 10-20 minutes in comparison with the wet standard, followed by dropping and rinsing

Antichloring: Antichloring treatment is required as traces of NaOCl is left on the fabric that forms hypochlorous acid. This may yellow and weaken the fabric. Antichloring with hydrogen peroxide brightens undyed lyocell part, increases the fabric contrast and leaves no significant odour. Typical steps include:

-

The bath temperature is set at 600C

-

pH of the bath is adjusted at 9 with soda ash

-

1 g/l 50% hydrogen peroxide is added and run for 10 minutes

-

The fabric is dropped and rinsed

Limitations of bleaching wash:

-

The same level of bleaching is very difficult to achieve in repeated runs.

-

Bleaching treatment sometimes damages the cellulose, resulting in strength losses or pinholes at the seam and pockets.

-

Bleaching liquor is harmful to human health. This may also causes corrosion to machine parts.

-

Bleaching treatment needs antichlor treatment to eliminate the subsequent yellowness in the fabric.

Enzyme wash: To minimize the adverse effect of stone-washing, denim garments are washed with enzymes. The enzyme breaks the surface cellulose fibers of the denim fabric

and is removed during washing. During the process, however, some amount of indigo dye and cellulose fibres from the surface of the fabric get removed.

Enzyme washing is also known as 'Bio-stoning'. The enzymes used are 'cellulases'. A cellulase enzyme can be classified according to pH range in which these are more effective, such as acid, neutral and alkaline stable cellulases. However, the first two types are commonly used. The working pH range of acid cellulase is 4.5-5.5 at a temperature of 500-550C while that of neutral cellulase is 6-7 at a temperature of 500-550C.

Generally, neutral cellulase is preferred due to a little or no back staining and lesser loss

of strength and weight. However, acid cellulases are cheaper and have shorter enzyme cycle timecompared to neutral ones. Cellulase enzymes are used in stone washing process. With cellulases, less stones are required and it causes less damage to the machinery and fabrics. Cellulase treatment on fabric reduces fuzz and pills; increases smoothness, softness, lusture and brightness; improves fabric handle and drapeability; and increases the wash down effects.

Typical enzyme wash process for denim is as following:

-

The bath material to liquor ratio is set at 10:1 at 50o-55oC.

-

Neutral/acid cellulase enzyme of 0.5% to 2% (on weight of garments) is added. This ratio varies depending on the intensity of the fading.

-

Bath pH is suitably maintained.

-

It is run out for 30-60 minutes depending on fading requirements at 50o-55oC.

-

The enzyme deactivation process is carried out by increasing the bath temperature to 80oC and then it is dropped and rinsed.

Advantages of cellulase treatment:

-

Cellulase is economical and environment-friendly compared to stone washing using pumice stones. The percentage of fabric damages is reduced. The enzymatic treatment of denim fabric ensures the same result by consuming less water and time, resulting in less waste and damage to machines. The pollution, quality variability and imperfections also reduce.

-

The enzymes can be recycled.

-

The productivity of washing rises as the space formerly taken up by pumice stones in the washing machines can now be filled with more pairs of jeans.

-

The time consumed for removing stone fragments from the garments is eliminated.

-

The duration or number of rinse washing after enzyme treatment is less than stone washing.

-

A small quantity of enzyme can replace several kilograms of pumice stones during washing that ultimately leads to less damage to the garment and machine and less pumice dust.

-

A soft handle and better appearance is achieved.

Disadvantages: There may be chances of back staining in cellulase treatment. To remove that, the garments are rigorously washed. However, this raises water usage.

Acid wash: Acid wash on denim jeans is becoming very popular due to its significant contrasts and attractive colours. Acid wash can be carried on fabric garments with indigo

and sulphur base. It strips the material's top layer of colour, making it whiter and giving an overall faded look.

This wash is carried out by soaking stones in bleach, followed by neutralization of the acid. It is normally carried out by tumbling the garments with pumice stones presoaked in a solution containing sodium hypochlorite (5-10%) or potassium permanganate (3-6%). This causes localised bleaching that produces non-uniform sharp blue/white contrast. In this wash, water is not added. The colour contrast can be increased by optical brightening treatment.

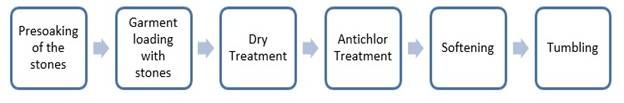

Figure 6: Flowchart for lyocell denim acid wash

Acid washed denim fabric sometimes become yellowish after washing. This is due to incomplete neutralization, washing or rinsing, so that manganese is not removed from the garment. However, manganese can be removed by washing with ethelene diamine- tetra-acetic acid as a chelating agent. The process involves soaking of porous pumice stones and chlorine or potassium permanganate (PP) bleach. Sodium-bisulfate is used for neutralisation. It is recommended to use two separate washing machines for acid washing and neutralization.

Acid washing process on denims: Porous pumice stones is soaked in chlorine or PP bleach solution for about 20-60 minutes. After the stones are completely soaked, the excess water is removed. Then the stones and the garments are put in a washing machine

for about 20 minutes. In this process, there should not be any single drop of water. The drain should be open during the process. When the required look is achieved, then the fabric is transferred into another washing machine for a regular washing for neutralization. After neutralization, the garments are dried.

Over dyed/tinted denim (monkey look wash): Over-dyeing/tinting of denim is an additional dyeing treatment that is normally carried out on stitched jeans. This adds another tone of colour to the jeans. Normally denim garments are over-dyed with yellowish dye for a dirty look. Tinted/over-dyed denims offer a vintage and muddy look. Tinting is normally carried out after the stone wash process. A little amount of tint or colour is added to the garment to change the hue or cast or tone of the indigo shade. However, when the quantity of tint increases, it covers up indigo. A variety of dyes, such as direct, reactive, pigment and sulphur, are used in this process.

The tinting process normally takes five to 15 minutes. This is followed by dye fixing, which cleans up of the superficial dye. As it consumes more water and chemicals, an alternative method has been developed, in which novel colour-based enzymes are used. This process allows tinting and stone washing to be carried out in a single bath. The advantages of the new technique include consumption of less water and energy, lesser process time and no use of extra chemicals. Chances of patches or unevenness in the garment are almost nil.

Laser marking/spray painting: This is a computer-controlled technique through which different patterns or designs, such as pictures, images, lines or text, can be drawn on denim garments. Chemicals or pigments are sprayed on the fabric to draw different patterns, followed by curing. Advantages include no use of water, zero effluent discharge, negligible chances of human error, excellent reproducibility and higher productivity, less maintenance and cleaning of machines, less time consumption and no adverse effect on fabric strength.

Ozone fading: In this technique, the garment is bleached with ozone dissolved in water in a washing machine. However, it can also be carried out in a closed chamber by using ozone gas. Advantages include minimum loss of strength and the ozonised water can easily be de-ozonised by ultraviolet radiation in this simple environment-friendly method.

Quick wash denim: Denim fabric manufacturers always want to minimize wash cycles. In quick wash denim, the fabric is dyed with a modified dyeing technique so that during the shorter wash cycle, the indigo dye can be easily removed. The treatment procedure consumes less water and chemicals and requires less time for washing, retaining fabric strength. By controlling the ionic form of indigo and cellulose in the dye-bath, the uniformity of indigo dyeing can be achieved. The alkalis used and pH conditions of indigo dye-bath produce stable colour yield.

Its advantages include use of lesser amounts of indigo dye, enzymes and oxidizing agent, uniformity of shade as streaks are avoided in the garment through the use of a modified alkali-pH-controlled system and reduction in washing time by 20-30 per cent.

Super stone wash: The garment is subjected to prolonged stonewash treatment for over six hours. Soda ash and soap are used for hard wash. Steam is used at 600-800C for an hour to finish the process, followed by an acetic acid wash treatment. The garment is then neutralised and rinsed.

Sand wash: This is carried out with pumice stones, enzymes and sand and offers an aged look to the denim.

Rinse wash: The garment is washed at about 500C in a hot bath, with softeners used at times.

Vintage denim: The garment is subjected to heavy stonewashing or a cellulase enzyme wash, with or without bleach for showing an old and worn look.

Sun washing: This imparts a sun-faded appearance to the garment. It is carried out by bleaching and stoning.

Super dark stone wash: This offers an extra dark indigo colour obtained through a double-dyeing technique.

Snow wash: This is a variation of acid wash. It gives bright white highlights.

Ice wash: In this process, almost half of the dye is removed during washing.

Dirty finish wash: After stone wash treatment, the garments are dyed with special chemicals to offer a dirty look.

Soft feel denim: Silicone softeners are added at the garment stage in this process.

Mechanical washes

Stone wash: Stone washing of denim fabric offers an used or vintage look to the garments. This is due to the varying degree of abrasion in the garment. Traditional stone washing is normally carried out with pumice stones to achieve a soft hand and desirable look. Round or oval pumice stones with a rough surface work as an abradant in the washing cycle. The variations in shape, composition, hardness and porosity gives different washing effect in the fabric. During washing, these stones scrap off dye particles from the surface of the yarn, which shows a faded, worn out and brilliance effect in the fabric. Due to ring dyeing of denim fabric and heavy abrasion during stone washing, the fading is more apparent but less uniform. The process makes the garments more supple for comfortable fit.

Figure 5: Flowchart for lyocell denim stone wash

To get the desired wash effect, the stone should be of proper hardness, shape and

size. For heavy weight denim fabric, large and hard stones are suitable and also last longer. Similarly, smaller and softer stones are suitable for light-weight fabrics. The degree of colour fading during this process depends on several factors, such as garment to stone ratio, washing time, size of stones, material to liquor ratio and load of garments.

The washing time may vary from 60 to 120 minutes. Stones may be reused until they disintegrate completely.

Pumice is a natural volcanic stone used in stone washing due to its durability to chemical treatment. It is crystallized with substantive pores.

A typical stone wash process for denims involves the following steps:

-

The bath material to liquor ratio is set at 10:1 at 600C.

-

Pumice stones are added in ratio of 1:1 stones/garments loading. This ratio varies depending on the intensity of the fading.

-

Other chemicals are added.

-

Run out for 15 - 60 minutes depending upon the fading requirement,

-

Drop and rinse.

Limitations of pumice stone usage:

-

Stones may cause fabric wear and tear and damage the washing machine.

-

Proper disposal of waste of the grit produced by the stones is a problem.

-

It raises the labour cost to remove stone dust from the garments, which require several washes for complete removal of stones.

-

It may cause back staining and re-deposition.

-

The process is non-selective.

Metal buttons and rivets in the garments and the drum of the washing machine sometimes get abraded, which affects the quality of the garment and the life of the equipment.

Alternative to pumice stone: To find an alternate to pumice stone, synthetic stones have been introduced. These stones are produced from abrasive material such as silicate, plastic, rubber or Portland cement. The advantages of synthetic stones are:

-

These are more durable and can be repeatedly used for 50-300 cycles.

-

The washing effect may be manageably reproduced.

-

These cause less damage to machines and garments.

Perlite stone wash: This is a new process. Perlite is a naturally occurring silicon rock, containing 2-6 per cent water. When heated at a particular temperature, perlite expands 4 to 20 times of its initial volume. These properties make it suitable for this process. The damage to washing machine is lesser and it gives better supple and softer finish to garments.

Sand blasting: Localised abrasion or colour change on the denim garment is created in this process, which involves blasting an abrasive material in granular, powdered form at a very high speed and pressure through a nozzle onto certain areas of the garment, such as knees and elbows. The treated surface shows a distressed, abraded or used look. The common blasting materials used are sand and metal granules.

During this process, the garment is first subjected to stone wash to the desired

degree of washing. A solution of sodium hypochlorite or potassium permanganate is often sprayed on the desired garment area to obtain the same look. The garment is then neutralized, rinsed and softened. The process is water-free and therefore, no drying is required.

Destroyed/damaged/used/whiskers: Whiskering, also known as 'cat's whiskers', are the crease lines around the crotch. Whiskering can be done on the sides of knee and on the back of the knee. During natural wear, pigments get removed in a portion of the crease.

That look is achieved by cutting the edges at different areas before washing, such as at the bottom, back pockets and the fly and knee areas.

Waterjet fading: In this method, one or both surfaces of the garment are exposed to hydro jet nozzles that offers a pattern effect to the garment and improves the surface finish, texture and durability. As no chemicals are used, the process is environment-friendly and economical. Colour fading is achieved without affecting the fabric strength or durability or warp shrinkage.

Fraying wash: Some selected areas of the pair of jeans are sanded to create a 'worn' effect. In others words, fraying is the destruction of denim fibres in selected areas, such as waistbands, pockets or hem of the jeans.

Torn denim: Some pairs of jeans are torn at a few parts for a naturally-torn look. The fabric has rips, holes, tears and lacerations.

About the author: Alkesh Darji heads the wet processing & technical services division of Textile Research & Application Development Centre (TRADC), Birla Cellulose at Kosamba, Gujarat.

20240830145908.gif)

20240924091633.png)

20240924111837.jpg)

Comments