In wet processing one of the important points to achieve better result is to have even application of dyes/chemicals/water to get even results.

This is possible through pioneered Swimming Roll technology by following flexibilities:

Uniform linear pressure over the entire roll width also with varying total pressures

Optimum nip-control by two "S-Rolls" with continuous deflection control by giving maximum flexibility

Service free pressure application unit

Dye-liquor through, lifted and lowered pneumatically, tailored to the process (with heating & cooling), minimum liquor content with full process safety

Optimum control of dye liquor composition

PLC-controlled auto cleaning, with minimum water consumption.

Optimised troughs:

For various processes and fabric qualities

With integrated heat exchanger

Improved access to the fabric path

Optimised fabric guiding for all fabrics:

Low fabric tension

Short fabric paths

Easy upgrading through building block system

Combined woven/tension sensitive fabric selectable

Quick and easy fabric thread up

Sophisticated applications:

For critical dye technologies with a wider range of adjustment

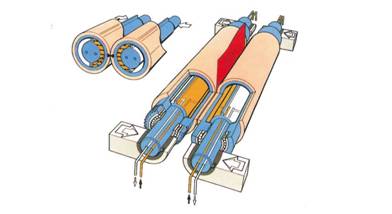

Function examples of Padder with 2 S-Rolls

Controlled even and uneven linear pressure

Technical data of Dye Padder:

Number of S-Rolls: 2

Trough Capacity: 22-80 Litre

Linear pressure: 12-50 N/mm

With the deflection controlled S-Roll, maximum pressure can be achieved (50 N/mm & more). This pressure is infinitely variable from minimum (basic load) to maximum, maintaining a constant uniform nip pressure. A characteristic feature of the S-Roll technology is the small roll diameter and the fact that there is no need for any crowned roll.

This guarantees a maximum specific pressure, an absolutely even squeezing effect over the entire width of the roll nip, controlled even or uneven linear pressures.

S-Roll Dye Padders, S-Roll Mangles and High Efficiency Squeezers by Kusters Calico under Jagenberg Group, are the most efficient solutions.

Comments