Mercerising is a treatment that adds value to cellulosic fabrics. It is a process of treatment of cotton or viscose fabric with highly concentrated caustic soda, under tension. Mercerisation is possible for both woven as well as knitted cellulosic fabrics. Mercerisation improves the dyeability of such fabrics and imparts dimensional stability and tensile strength to these fabrics. The lustre which is obtained through mercerisation stays permanently with the fabric and additionally this treatment gives a soft feel to the fabric, thus giving greater comfort to the end user. With the emphasis on comfortable clothing growing every year, mercerised knitted fabrics are in great demand for making garments.

Emerging trend: Open width knit processing

Indian knit processors have realised the immense benefits of switching over from tubular to open width processing for knit fabrics. Several processors in the country have already converted their knit process houses to open width bleaching, cold pad batch dyeing and washing.

The knit mercerisation uptrend has been prevalent since over 15 years. However, the growth in knit mercerisation was constrained as it so far was applicable only for tubular fabrics. Tubular mercerisation has its own limitations - it creates visible marks on the edges of fabric and it also causes a lot of effluent treatment issues due to the high chemical oxygen demand load per unit of fabric treated. This is where the development of the open width knit mercerisation process has helped considerably, as this process not only mitigates these issues faced by tubular mercerisation, but also improves the quality of fabric in terms of feel and comfort. It also has higher savings in dyeing related processing costs as compared to unmercerised cotton knits. Soon, we expect that open width knit mercerisation will be an integral part of the sequence of knitted fabric processing.

Goller's brief introduction

Goller is a pioneer and a global market leader in the manufacturing of open width textile processing ranges, including those for knit mercerisisation. Goller was founded in Germany in 1948, and became a member of the CHTC Fong's Group in 2006. The integration of Goller into the CHTC Fong's Group helped it to develop and spread at a tremendous rate its highly engineered textile wet finishing ranges for the textile industry. Goller has assembled 239 ranges for woven fabric and 174 ranges for knitted fabric in its Shenzhen factory since 2007.

The benefits of Goller open width knit merceriser

Better absorbency properties obtained in mercerised fabric as compared to unmercerised fabrics

Saving of dyes up to 15-20% when compared to unmercerised varieties

Achieving excellent colour depths, especially medium dark or dark shade printed fabric

Less pilling

Less shrinkage of finished fabric in domestic washing

Higher quality compared to tubular knit mercerisation

Lower utility consumption per unit of fabric as compared to tubular knit mercerisation

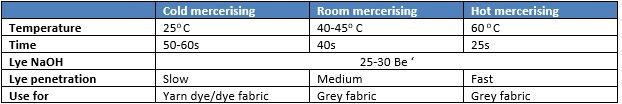

Different process conditions applied in open width knit mercerization

Cold/room/hot mercerising

Technical and utility data of Goller knit mercerisation:

-

Process: dry on wet, room mercerising (wet on wet/cold/hot as option)

-

Fabric quality: 100% cotton, cotton/viscose blends at lower caustic strengths

-

Production speed: 20-30 or 30-40m/min configuration available

-

Chemicals: caustic soda, acetic acid

-

Caustic consumption: approx. 140g/kg of fabric @25Be

-

Water consumption: approx. 5 - 6 [L/kg]

-

Steam consumption: approx. 0.5 - 0.6 [kg/kg]

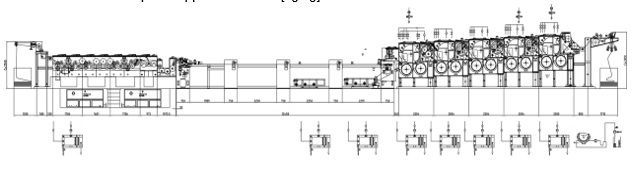

Typical lay out of a knit mercerisation range

Success story of Goller open width knit mercerisers world wide

Goller has already successfully installed 8 open width knit mercerisers worldwide including one commissioned recently in a knit process house at Kolkata. Considering the benefits and current trends, open width mercerisation is no doubt the way forward for open width knit processing factories in India.

Comments