Why do we need print paste automation?

Textile printers use dyes either in powder or liquid forms for their printing needs. In fact, 90 per cent of printers use only powder dyes, such as reactive and disperse powder dyes (though these have to be first dissolved before application, and always need to be prepared fresh before every application). Only 10 per cent of printers use liquid pigment dyes. Liquid dyes need separate storage tanks and need to be kept in constant circulation in order to avoid sedimentation and spoiling of the entire batch. So, in both cases the dye preparation process is one that requires care.

Other issues faced by printing department of the dye houses are:

Excess prepared print paste goes waste

Stored print paste becomes hard and cannot be made fluid again

Large area is required for storing the ready paste carboys for the whole day's printing

Human error in handling the print paste

Inconsistency in paste preparation

Print right the first time with Color Service

These colour preparation challenges can be easily overcome by installing an appropriate automatic print paste dispensing system in a dye house in printing department.

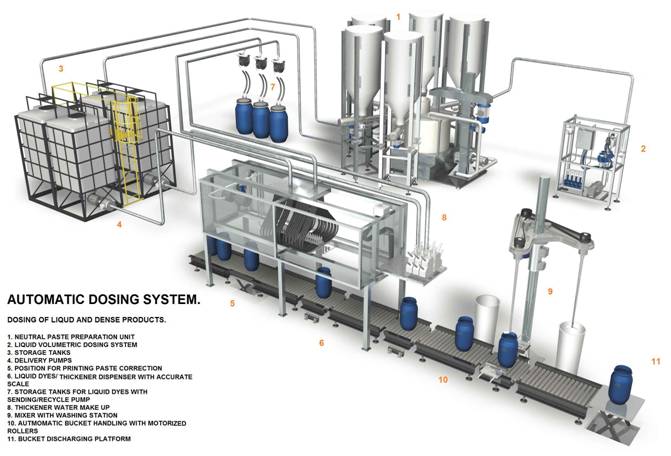

Color Service, a world leader in automatic dosing system, has an innovative solution that allows a printing department to use both powder and liquid dyes in the same dosing system. The Color Service automatic printing colour kitchen is composed of two main units - a thickener preparation unit and a paste dosing unit. Both units can work either in standalone mode or together.

Thickener preparation unit

Thickeners such as alginate, guar gum imparts stickiness to print paste so that it may be applied on the fabric surface without bleeding and it helps in maintaining design outline.

Thickener preparation for printing requires special care. The addition of chemicals needs to be precise and the viscosity needs to be maintained in order to ensure good quality print (manual addition of chemicals can change the composition of the mix). When thickeners are mass produced and stored for a long time, it may affect the viscosity and render the whole mix useless. Hence, the best practice is to make fresh thickener daily as per the expected consumption.

The thickener preparation unit from Color Service cooks the thickener automatically with minimum manual intervention. All powder and liquid ingredients can be dispensed automatically and can work with different recipes. The unit is equipped with fibreglass silos (supplied by Color Service) for powder chemicals and liquid chemical dispenser to add powders and liquids in to the mixture. The unit not only allows setting the quantity but also the order of powders and liquids that needs to be added in the mix. A powerful stirrer along with a scraper stirs the mix perfectly and gives a homogenous thickener. The thickener is delivered to a storage tank via a gear pump and a collector.

Each thickener tank is equipped with a level sensor to measure the quantity of the thickener. There are two different filling services - a blower pump for powder dyes and a pneumatic diaphragm pump for liquid. Except for filling of powder silos and liquid chemical tanks, the operator does not have to do anything during the entire process. All silos for powder and liquid are equipped with level sensors. Depending on the consumption, filling operation can be done daily or on weekly basis.

Printing paste dosing unit

The dosing unit of the Color Service automatic print colour kitchen prepares the printing paste in a small or big quantity based on the customer's recipes. This unit has a unique function in it that allows the direct dosing of powder.

Depending on the quantity of print paste required, the unit picks up a drum and delivers it to an initial thickener dosing head. Just a small amount of thickener is dosed here from the drum in order to avoid sticking of the dyes. The unit then adds dyes on the initial layer of the thickener.

Depending on the quantity of print paste required, the unit picks up a drum and delivers it to an initial thickener dosing head. Just a small amount of thickener is dosed here from the drum in order to avoid sticking of the dyes. The unit then adds dyes on the initial layer of the thickener.

For liquid dyes such as pigments, dosing can be done with the same thickener dosing head. But for powder dyes, the drum goes to a powder dosing unit on a conveyor. On completion of powder dosing, the drum goes back to paste dosing unit. The drum is moved to the next stage to complete the remaining amount of thickener. A label is put on the drum to identify the content, batch, print machine, etc, before it goes to a stirrer unit.

What sets the Color Service stirrer unit apart from ordinary stirrers is that it allows mixing powders and liquids together. The drum is turned as well as the stirrer travels up and down for proper mixing. There are two stirrers that are used alternatively. One stirrer mixes the drum, while the other goes for washing.

This arrangement allows simultaneous operation. The whole unit is divided in 3 stages: thickener initial layer dyes dosing, final thickener dosing, and stirring. On stage-wise completion of work, the drum passes to the next stage and a new drum is placed.

Advantages of the Color Service print paste automation dosing system:

1. Reduced chemical and dye wastage

2. Reduced human errors

3. Less time consuming

4. Reduced energy consumption

5. Increased productivity

6. Lower labour cost

7. Backward tracing

With an increased demand for rotary and flatbed printing machines, the demand for printing paste automation has shown an upward trend. It is quite evident that green field projects need to install print paste automation system to achieve higher quality standards. However, it is even more essential for existing printers, having two or more printing machines in their dye house, to set up an automatic print past dosing system for better quality, increased productivity and faster return on investment.

Color Service and A.T.E. have successfully installed this system at leading customers such as Arvind Mills, Himatsingka, Shahi Exports and Auro Textiles.

Comments