Textile fibres have different applications depending ontheir characteristics and special properties. Pradeep Kulshrestha presents anoverview.

Textile fibres have different applications depending ontheir characteristics and special properties. These are broadly classified intonatural and man-made fibres (MMF). Nowadays, technical application of MMF hasincreased with innovative developments. Fibre composites containing carbonfibre-reinforced plastic is the advance material innovation for light weight savingsand have more advantages. Contribution of high tenacity polyester, nylon,aramid, and dyneema is boosting businesses with more profit margins intechnical textiles and composites.

Classification ofTextile Fibres:

Staple fibre is a short length fibre of varying lengthbetween 0.5 inches and 2 inches. It forms the base for yarn. These are commonlycalled polyester staple, viscose staple and nylon staple. Filament fibre is acontinuous fibre of indefinite length. Bunching of filament or imparting alittle twist can be used directly for weaving.

Characteristics andapplication of MMF

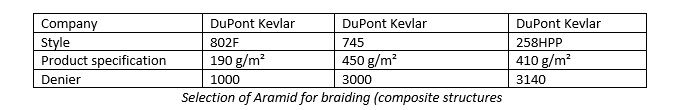

Aramid: It does not melt,is highly flame-resistant, maintains its shape and form at high temperaturesand has high resistance to stretch. It is used in protective clothing, hot gas

filtration fabrics, protective vests, military helmets, structural composites for boats and aircrafts, sailcloth, ropes, cables and marine and sporting goods.

Acrylic:

These are soft and warm, resemble wool, retain shape, are resilient, can dry

quickly and are resistant to moths, sunlight, oil and chemicals. These are used

in infant wear, knitted garments, dresses, fleece and pile fabrics, jerseys,

carpets, blankets, awnings, auto tops and industrial fabrics.

Acrylic:

These are soft and warm, resemble wool, retain shape, are resilient, can dry

quickly and are resistant to moths, sunlight, oil and chemicals. These are used

in infant wear, knitted garments, dresses, fleece and pile fabrics, jerseys,

carpets, blankets, awnings, auto tops and industrial fabrics.

Acetate: These have a luxurious feel and appearance, are available in a wide range of colours and lusture, have good drapability and softness, dry relatively faster and are resistant to mildew. These are used in blouses, slacks, sportswear, brocade, crepe, tricot, draperies, upholstery, cigarette filters and fibres for pillows.

Bicomponent: These super fine fibres are selfbulking and thermally bonded, have a unique cross section and offer the functional ability of special polymers in a cost-effective manner. These are used in uniform distribution of adhesives, lamination and environment-friendly and recyclable products.

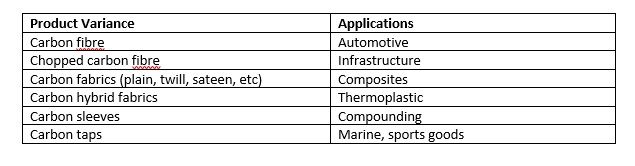

Carbon: Carbon is manufactured into tiny fibres through either the PAN or pitch process. It is manufactured in bundles of thousands of tiny filaments and wound onto a roll or bobbin. These carbon fibre rovings comprise thousands of filaments. Carbon fibres are used in wind turbine blades, automotives, braiding composite applications, carbon rings , half rings, Italian arches, carbon rods for artificial limbs and carbon product variances.

Lyocell: These are soft, strong and absorbent with good dyeability. These are used in dress, slacks and coats.

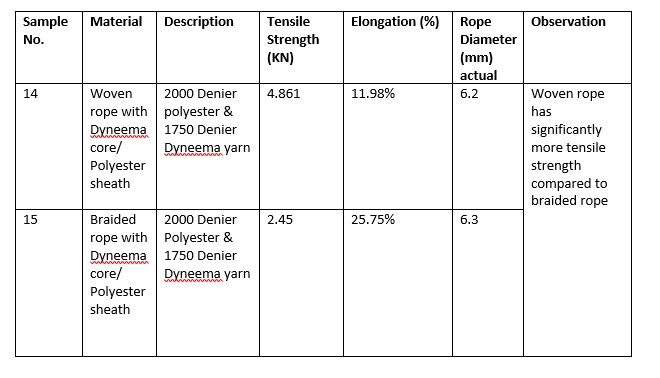

Dyneema: These are made from ultrahigh molecular weight polyethylene and offers maximum strength with minimum weight. While Aramid fibre Kevlar tends to absorb 3.5 per cent of its own weight in water, Dyneema absorbs no water. Kevlar is considered seven times stronger than steel, while Dyneema is 15 times. These maintain its performance in humid conditions. Dyneema is used for rope for marine applications, fabric, mesh and braided fishing line.

Comparison of woven and braided ropes prepared from Dyneema and polyester fibres

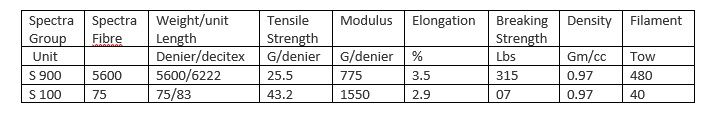

Spectra and Dyneema Fibres:

Spectra fibres can enhance fabric by improving tear strength and abrasion resistance. These are used in rope, fishing line, fabric and protective gloves.

Spectra fibre specifications are

shown below:

Spectra fibre specifications are

shown below:

Dyneema has a slightly different molecular structure than Spectra and higher breaking strength in the larger diameters. It displays slightly better wear characteristics in heavy use areas, but has more elasticity than Honeywell's Spectra 1000.

Modacrylic: These are resistant to abrasion and flame, dry quickly, are soft and resilient, are resistant to alkalies and acids and retain their shape. These are used in deep pile coats, simulated fur, knit pile fabrics, awnings, carpets, blankets and scatter rugs.

Melamine: These have low thermal conductivity, are resistant to flame, have high heat dimensional stability and can be processed using standard textile equipment. These are used in fire blocking fabrics (aircraft seats), protective clothing, insulating thermal liner, heat-resistant gloves and molten metal splash.

Nylon: These are exceptionally strong, resilient, lustrous, easy to wash, resistant to abrasion but have low moisture absorbancy. These are used in blouses, dresses, foundation garments, raincoats, bedspreads, upholstery, curtains, air hoses, conveyor and seat belts, ropes, nets, and in geotextiles.

Olefin: These are resistant to deterioration from chemicals, mildew, perspiration and weather, are sensitive to heat, light-weight but strong, dry quickly and are resistant to soil. These have applications in knitted sports shirts, undergarments, carpet backing fabrics, filter fabrics, laundry and sandbags, doll hair and industrial sewing threads.

Polyester: These are resistant to stretching, shrinking, wrinkles and abrasion, dry fast and are easy to wash. These are used in blouses, shirts, kidswear, tyre cord, curtains, ropes and nets.

Spandex: These can be stretched five times without breaking and come back to original length, are light in weight, and are stronger and more durable than rubber. These are used in atheletic wear, golf jackets and surgical hose.

PVA fibre: These are high-performance reinforcement fibre for concrete that are unique in their ability to create a molecular bond with mortar and concrete. Their specific gravity is 1.3 and have tensile strengths in the range 160,000 psi (1100 MPa)-203,000 psi (1400 MPa). These can be added to cement to give good water proofing qualities, are used in conventional concrete and are cheaper.

References

1.High Technology Fibres Part B - Jack Preston

2.Regenerated Cellulose Fibre - Calvin Woodings

3.Fibre Science and Technology - M. Lewin

4.Woven Belt and Ropes - ATIRA Research Project - Pradeep Kulshrestha

5.Dupont.com

6.Teijinaramid.com

7.Kuraray-poval.com

8.DSM Dyneema - Visit

9.ITEMA - Shanghai visit

20240830145908.gif)

20240924091633.png)

20240924111837.jpg)

Comments