This study is about the effect of some mechanical properties on poly-cotton (PC) fabric produced by keeping cotton as constant warp and having cotton and PC blend in weft with different pick ratio. It was observed that fabric having PC and cotton in 1:1 ratio in weft shows the highest value in mechanical properties. It can be concluded that anatomical difference plays a very important role in fabric properties.

Introduction

In the Indian market, PC blends have obtained substantial vogue. Remarkable cost limiting by reduction of polyester content in PC fabrics is achievable without affecting consumer interest.1 Fibre type, crimp, blend type, contraction and yarn structure affect fabric frictional properties.2By increasing polyester content, breaking strength and extensibility of polyester-viscose blend can be increased.3According to a study, the effect of finishing stages, i.e. scouring, bleaching, mercerisation and dyeing, on mechanical properties of PC blend fabric results in softened fabric after scouring and dyeing, whereas it gets stiffened after mercerisation and heat setting. Bending hysteresis, shear hysteresis and bending rigidity values decrease after finishing.4

As far as the effect of yarn properties on mechanical properties of fabric are concerned, thread pulling out force is inversely proportional, whereas thread breaking strength is directly proportional to tearing strength of the fabric. Strength of the fabric is also influenced by cover factor.5 There is a statistical model for predicting the strength of PC blend.6 With increase in warp and weft insertion frequencies, weight of fabric also increases. And fibre-type influences change in fabric thickness7.

Materials and methods

Materials: Fabric is produced by using polyester-cotton blend in weft having a blend ratio of 65:35 of 34s count. The 38 mm staple polyester fibre has a linear mass density of 1.2 denier, whereas cotton is having a micronaire value of 4. The blend ratio of polyester to cotton in the yarn is 65:35.

Five samples were prepared with cotton in warp and cotton and PC in weft at different pick ratio and plain as weave. In sequence sample 1 has cotton to PC ratio is 1:1, sample 2 is made by taking cotton both in warp as well as in weft, sample 3 has cotton in warp and PC in weft, sample 4 has cotton to PC ratio of 1:2, and sample 5 has the same ratio of 2:1.

Methods: Testing is done by standard methods and at 270 C and 67 per cent RH.

Three mechanical tests were examined. Breaking strength and elongation at break were examined by ASTM D5035 and abrasion resistance was examined by ASTM D3884. ASTM International, formerly known as American Society for Testing and Materials, is an international standards organisation that develops and publishes voluntary consensus technical standards for a wide range of materials, products, systems and services.

Fabric breaking strength: Also known as tearing strength, it refers to the supreme tensile force when material is extended to smash. And it is used to assess the potential of fabric to withstand tensile harm.

- Factors affecting strength are the strength of a single thread, structure-higher strength is observed in loosely-structured fabric, smooth yarns (show higher strength), thread movement (whose reduction results in a fall in strength), and special fabric finish like crease-resist (that reduce strength).

-

Elongation at break or fracture strain: It explains the difference between changed length and initial length after the test specimen breaks. Force is applied to material until it breaks.

Factors affecting strength are machine capacity, clamping problem, effect of temperature and humidity, length of specimen and rate of loading.

- Abrasion resistance of fabric: This is the potential of fabric to hold out against surface wear created by rubbing touch with another specimen.

Factors affecting abrasion resistance are the following:

a. Fibre-type: high elongation, elastic recovery and work of rupture are examined to be chief aspect.

b. Yarn twist: Most favourable twist increases the abrasion resistance.

c. Fibre properties: Longer fibre helps in better fabric abrasion resistance.

d. Fabric structure: If one section of yarn has domination on surface, it helps in better abrasion resistance.

e. Fibre diameter: Optimum increase in fibre diameter enhances abrasion resistance.

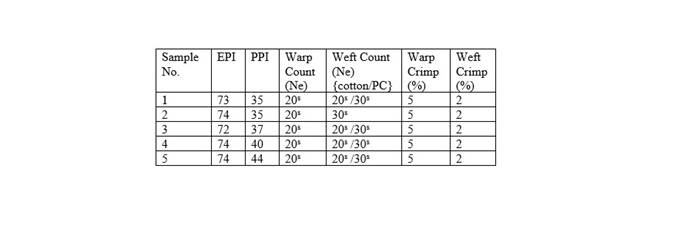

Basic data of samples are given in table no. 1

Results

Results

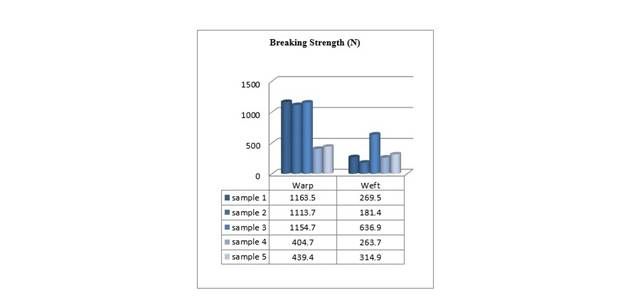

Breaking strength: Sample 1 shows the greatest breaking strength warp-wise, whereas sample 4 shows the lowest breaking strength. The weft sample 3 has highest value and sample 2 has the lowest.

Chart No. 1 below shows the complete data of breaking strength.

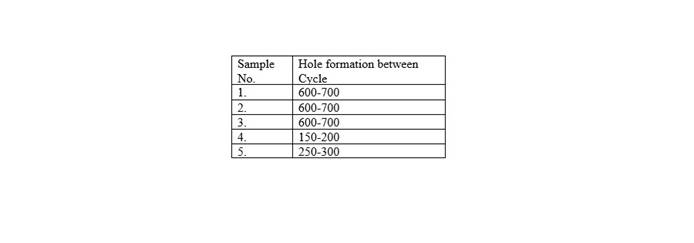

Abrasion resistance: Samples 1, 2 and 3 have the same values that are the highest as well and sample 4 has the least value among all. Data is given in following table.

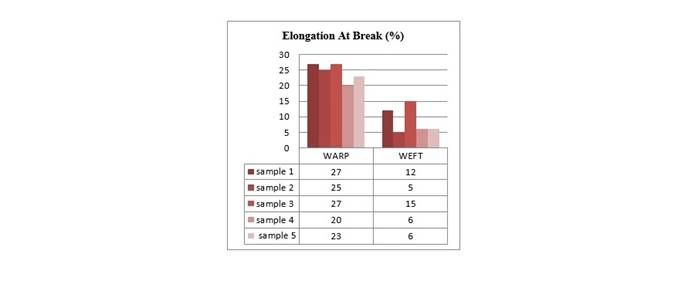

Elongation at break: Samples 1 and 3 have the same highest value of elongation at break warp-wise, whereas sample 4 has the least value. Weft-wise, sample 3 has highest value and sample 4 and 5 have the same least values.

Chart No. 2 below shows the complete data of elongation at break.

Conclusion

Significant difference in properties of fabric produced by keeping cotton (20s) as constant warp and using polyester-cotton (65:35) and cotton in weft with different pick ratios have been observed in this experiment. Three mechanical properties were examined: breaking strength, elongation at break and abrasion resistance.

I. Breaking strength: sample 1 (warp-wise) and sample 3 (weft-wise ) has the highest value.

II. Elongation at break: samples 1 and 3 have 27 per cent value (warp wise) and sample 3 has the highest value of 15 per cent (weft-wise).

III.Abrasion resistance: samples 1, 2 and 3 have good abrasion resistance among all five samples.

References:

1. G V Sarma, Surinder Singh, B C Verma & Anu Sakhuja, "Influence of Blend Composition and Weave on Some Mechanical Properties of Polyester-Cotton Blends", Indian Journal of Textile Research, Vol. 5, December 1980, 114-121.

2. A Das, V K Kothari & V Nagaraju, "Frictional Characteristic of Woven Suiting & Shirting Fabrics", Indian Journal of Fiber & Textile Research, Vol. 32, September 2007, 337-343.

3. G S Bhargava & R K Yadav, "Effect of Blend Composition & Fabric Set on Some Characteristics of Polyester-Viscose Fabrics", Indian Journal of Textile Research, Indian Journal of Textile Research, Vol.8, December 1983, 115-120.

4. V Natarajan, G Thilagavathi & V Sankaran, "Studies on Low-Stress Mechanical Properties of Polyester-Cotton Suiting Fabrics", Indian Journal of Fiber & Textile Research, Vol.22, June 1997, 99-111.

5. I C Sharma, Sudeep Malu, Pankaj Bhowan & Surender Chandna, "Influence of Yarn and Fabric Properties on Tearing Strength of Woven Fabrics", Indian Journal of Textile Research, Vol. 8, December 1983, 105-110.

6. Tanveer Hussain & Zulfiqar Ali Malik, "Prediction of Tearing Strength of Polyester/Cotton Blended Woven Fabrics", Indian Journal of Fibers and Textile Research, Vol. 35, September 2010, 243-249.

7. Erkan Turker & Necla Yaman Turan, "A Research on the Investigation of Physical Properties of Polyester/Cotton Fabrics", Journal of Textile Engineering & Fashion Technology, Vol. 4, January 2018.

8. Mourad M, M H Elshakankery & Alsaid A. Almetwally, "Physical and Stretch Properties of Woven Cotton Fabrics Containing Different Rates of Spandex", Journal of American Science, 2012, 567-572.

9. Jahan I, "Effect of Fabric Structure on the Mechanical Properties of Woven Fabrics", Advance Research in Textile Engineering, Indian Journal of Fiber & Textile Research, October 2017.

10. Tapas Ranjan Kar & Arvind Pandharpure, "Influence of Weave Structure on Low-Stress Mechanical Properties & Total Hand Values of Cotton Fabric", Indian Journal of Fiber & Textile Research, Indian Journal of Fiber & Textile Research,Vol.44, March 2019,75-82.

11. Zulfiqar Ali Malik, Mumtaz Hasan Malik, Tanveer Hussain, Farooq Ahmed, "Development of Models to Predict Tensile Strength of Cotton Woven Fabrics", Journal of Engineered Fibers and Fabrics, December 2011.

12. B V Vasumathi, T H Somashekar, S L Chilakwad & G Shrikanth, "Studies on Abrasion Resistance of Silk Fabrics", Indian Journal of Fiber & Textile Research, Vol. 29, March 2004, 69-73.

Comments