Luscher is a leading global manufacturer of state-of-the-art imaging systems for various printing technologies used in the graphic arts and textile industries. Backed by 73 years of experience, Luscher manufactures many kinds of cutting-edge equipment.

JetScreen DX Round, Luscher's state-of-the-art UV laser diode direct exposing system, uses next-generation, long-lasting laser diodes to reduce the time it takes to produce high quality rotary screens with a maximum width of 3500 mm. The laser diodes enable significant time savings, since they expose screens at a high resolution with high speed. In addition, no consumables are required for JetScreen DX Round, which makes the overall screen making process greener, economical and more efficient.

Modular Design

JetScreen DX Round has a modular design and can be customised to suit special requirements of customers. The standard configuration includes a 1200 dpi setting head with 16 individually controllable laser diodes, with an option for 32 diodes. The 16 laser diode configuration exposes a screen coated with standard emulsion, a repeat of 640 mm, and a width of 2200 mm in less than 10 minutes. For a similar screen, the 32 laser diode configuration reduces the exposure time to 5 minutes.

Currently, the different types of imaging systems available are: masking with ink/wax, engraving, and exposing.

| Masking (with ink/wax) | Engraving | Exposing |

|

|

|

Exposing technology saves time overall compared to engraving:

|

Processes: |

Engraving technology |

Exposing (Luscher DX) technology |

|

Coating and drying |

✓ |

✓ |

|

Polymerisation |

✓ |

x |

|

Engraving/exposure |

✓ |

✓ |

|

Washing |

x |

✓ |

|

Drying |

x |

✓ |

|

Polymerisation |

x |

✓ |

|

Preparation |

x |

✓ |

Estimated time in minutes for 640 mm x 2800 mm screen:

|

Engraving technology |

Exposure technology | |

|

Imaging |

45 |

15 |

|

Washing Out |

15 | |

|

Drying |

30 | |

|

Total |

45 |

60 |

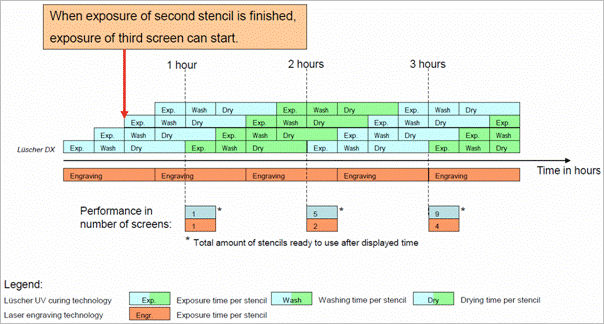

Although the number of steps are higher for the exposing system compared to engraving, the Luscher DX exposing system actually results in significant time saving. This is because once the exposure of one stencil is completed, the exposure of the second screen can be started immediately. The concurrent running of all processes considerably reduces the time required to make a screen.

As a result, at the end of four hours, the number of screens made using Luscher’s exposing technology is more than double of the number of screens made using engraving technology!

|

Number of hours |

Number of screens with engraving technology |

Number of screens with laser exposing technology of Luscher |

|

1st hour |

1 |

1 |

|

2nd hour |

2 |

5 |

|

3rd hour |

4 |

9 |

|

4th hour |

6 |

13 |

|

Total |

13 |

28 |

In addition, there are numerous benefits of JetScreen DX Round exposing technology over the conventional engraving technology:

-

High output quality

-

1200 dpi resolution ensures round dot withdiameter of 25 mm

-

Better quality half tone (or gradient) and raster(or dot matrix) images

-

Very low energy consumption of less than 1.5 kW

-

Laser diodes (16 diode or 32 diode configuration)work with constant energy efficiency

-

Plug and expose; easy installation

-

Easy change of screen by just unlocking one screen

-

User-friendly software

- Due to air pressure inside the screen, screens with dents can also be used

A.T.E. Enterprises Private Limited is responsible for the marketing, sales, and service of Luscher products in India. A.T.E.'s domain expertise coupled with Luscher’s state-of the-art technology will help textile printers take advantage of this technology to gain a competitive edge.

Comments