Sangam, in district Solapur, is a small village which is about 320 km south of Mumbai. In the early 80's a young boy saw his mother and father working in the nearby cotton fields. The thoughts of his parents working day in and day out stayed in his memory. Even when he completed his school education in the local government school, the memories didn't fade. As he grew up, he decided to create his future in the cotton sector but didn't know the background nor did he have any technical knowledge. The young man started a small business of pumps agency but the cotton fields always remained in his mind. By sheer hard work and backing of his father the young man decided to set up his own mill. During that time luckily, he met professor Chandrakant Patil who later became his mentor and guide. Professor Patil meticulously taught him the basics of textiles and took him to visit many mills in India.

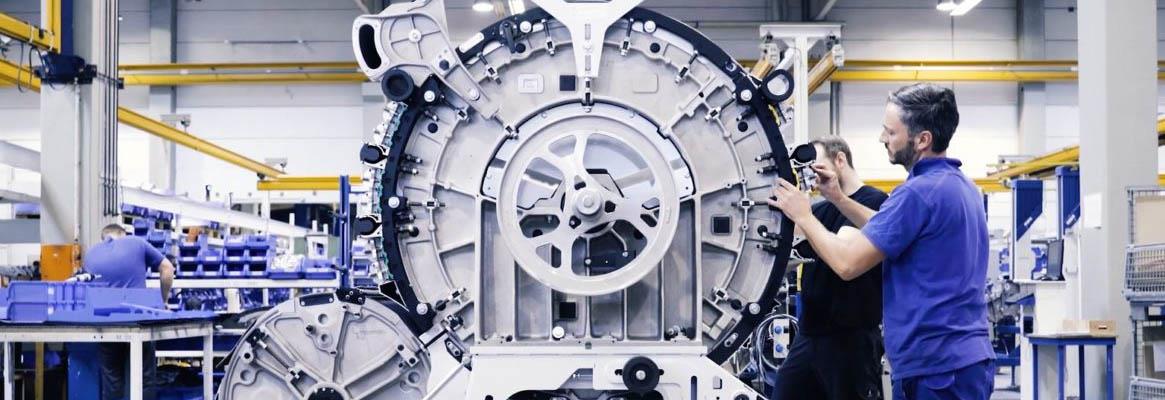

The young man today, Sanjay Tate-Deshmukh is the chief managing director of one of the most modern textile mills in India - Dhanasmruti Textile Mills. Equipped with Truetzschler blow-room line, 12 TC 10 cards, 3 TD 7 draw-frames, 1 TD9T draw-frame, 1 TSL 12 sliver lap, 5 TCO 12 combers and 5 TD 8 draw-frames, this 25,000 spindles project was recently fully commissioned.

During the planning phase Sanjay Tate-Deshmukh found out that the existing mills having Truetzschler preparatory and KTTM ring-frames had better yarn quality record than the mills having all the machines from a single manufacturer. Even the earlier experience of his father and now the director of Dhanasmruti Mills, Naryanrao Tate-Deshmukh echoed the same thoughts. Along with professor Patil, he also found out that almost all major spinning mills in India who had their own retail labels, had Truetzschler machines in their mills. After these findings it was but natural to have the latest Truetzschler machines in their mills.

Sanjay is ably assisted by Vijay Tate-Deshmukh, director and Vishal Magar, director, in their sales and marketing strategies. In the near future they plan to have a 40 per cent export component.

Balasaheb Koratkar, deputy GM, who is responsible for the day to day production and maintenance, is all praise for Truetzschler machines. He is happy that in a very less time they were able to attain 5 per cent Uster yarn quality norms with minimum noil levels. As a result, Dhanasmruti Mills has started to carve a name as a quality yarn supplier in India. He also said: "Even though its early days we are happy about the fact Truetzschler machines are very easy to maintain and are running smoothly since their commissioning. Especially the TCO 12 combers which I feel are better than the combers of other leading suppliers."

Sanjay Tate-Deshmukh said, "My mother had a dream that one day we, the sons of the farmers, would create big names for ourselves in the cotton industry. Keeping this in mind we have a vision to be the best quality fabric provider to the world by the year 2023."

Sanjay's mother, Shamal Tate-Deshmukh exclaimed "Hya machines mule jar majhya mulachi bharbharaat jhali aahe tar nakkich hyaa machines changlya asnaar" (If these (Truetzschler) machines are responsible for my son's success, then definitely they must be good).

Narayan Tate-Deshmukh also praised the important role played by the sales team of A.T.E. during the project's initial and also the implementation phase. He happily informed: "They were even available at midnight for discussions and gave expected satisfactory feedback to our queries."

Sanjay Tate-Deshmukh was upbeat in informing that they would proudly repeat Truetzschler machines in the next 25,000 spindle project.

As Shamal's dream has come true, it's safe to say 'It's True Its Truetzschler!'

20240504122856.png)

Comments