In times of increasingly scarce resources and increasingpollution, sustainability has become a central issue in the whole textileindustry.

Respect. Responsibility.

Weitmann & Konrad GmbH & Co. KG from Germany(WEKO) has been committed to this topic since its foundation in 1953. At atotal of three main locations, WEKO develops and manufactures fluid rotaryatomizers and powder coating systems for the resource-saving and contactlessapplication. Because the respectful use of our resources and our own responsibilityin our daily work are important to the entrepreneurial families.

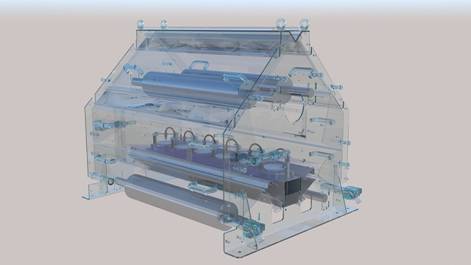

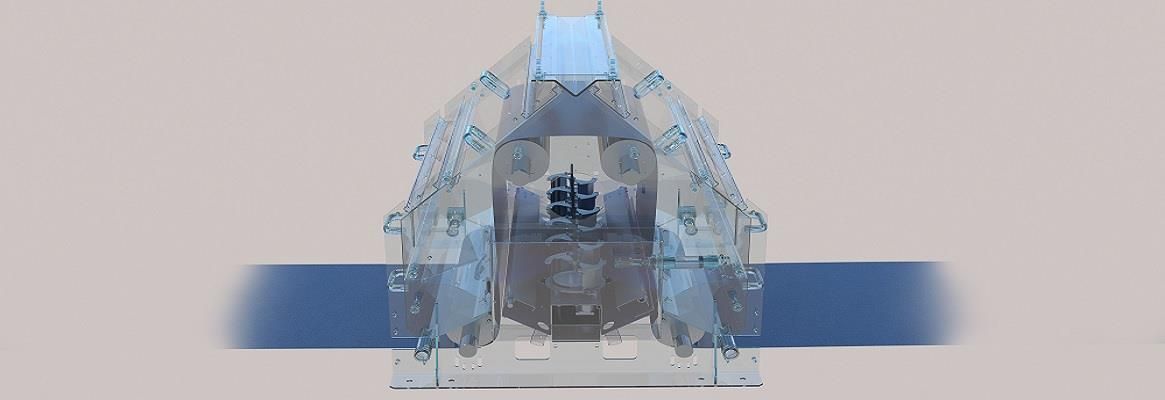

The WEKO principle is valued in the textile industryworldwide for exact and replicable moisture management, such as for compacting,sanforizing or shrinking. Due to the strong increase in demand for minimumorder quantities for either one-sided or two-sided application, WEKO hasdeveloped the systems significantly further in the past 5 years and hasincreasingly entered the area of functional equipment. With the encapsulated WEKO-ProTec,it was possible to achieve an extremely clean production environment and thusthe use of critical fluids, which is crucial for the area of technical textilesand nonwovens.

Revolution

With the latestdevelopment WEKO-NEO, in 2019, the equipment enables working with a largevariety of functional finishes which are common in the textile industry. Thanksto the contactless application center side variations (CSV) are not to befaced. Tailing can be reduced significantly since a bath contamination and bathequilibrium have not to be considered. Improve your finishing process whenapplying functional finishes likeSoftening, Easy Care finish, Sewability enhancement, Hydrophobization, Oil andsoil repellency, Flame retardancy, Fixation, Antimicrobial finish,Hydrophilization / water repellency or others. The use of auxiliaries and thenecessary dryer energy is significantly reduced by the exact amount regulationand the forced application. In the DENIM fabric production processes, such assulfur-topping / bottoming, Color denim, sandwich dyeing, color fixation,oxidation, sizing of DENIM warp yarn and overdyeing / tinting of DENIM fabricscan be achieved. Together with functional finishes applications as percustomer’s requirement can easily and efficiently be obtained in a costeffective and sustainable way.

Rotary atomizers offer the user some advantages which can't be covered or only insufficiently by alternative application methods, such as top process stability and reproducibility at any time. Rotary atomizers work in a non-contact manner and are therefore particularly gentle on the textiles to be finished.

Rotary atomizers belong to the category of mechanical atomizers. The breakdown of the fluid into micro-droplets takes place with the help of centrifugal force by rotating application bodies, the so-called rotor, in the form of flat plates which are supplied with fluid. The fluid itself doesn't need to be pressurized or nebulized with compressed air. The rotation of the plates accelerates the fluid towards the edge. There, fluid filaments are formed whose length is influenced by the viscosity of the fluid. Once the cohesion forces are overcome from a certain length, the threads disintegrate into droplets and a 360 spray angle is created. Based on water with a surface energy of 72.75 mN/m, these droplets assume a size between 30 and 80 um. A change in the rheological properties of the fluid due to additives / auxiliaries and the speed of the rotors influence the droplet size. Both, high speeds and a lower surface energy produce smaller droplets. A prerequisite for clean application with WEKO systems is the use of low-viscosity and water-based fluids. Shear stability and low foaming tendency under the influence of high mechanical forces must also be given.

Based on this principle, WEKO fluid application systems are used worldwide for non-contact moistening/conditioning and finishing of continuously moving webs in minimum application processes. Today, in addition to the textile industry, the areas of application include many others such as the nonwovens, tissue, paper, wood fibre board and film industries.

From Practice

While conducting a field test with a leading European textile manufacturer, the aim was to apply a soft-grip hand-feel improving agent to a 500 gsm fabric. It was observed that the wet pick-up got reduced by ca. 60 % while changing the pad application to WEKO rotor spray. The minimized water content in the fabric helped to double the production speed. Passing the drying in half of the time with the same setting ca. 60 % drying energy per linear meter was saved. Also during application of other functional finishes such as the color fixation or hydrophobization etc. very similar results could be achieved. This is possible due to the minimal application and the variable penetration level in contrast to conventional padding processes. Even more impressive are the savings on fabrics where the function is only needed on one side.

Your Benefits

• Repeatable quality

• High process stability

• One or both side application

• Raised product fastness

• Economical use of the auxilliaries

• Saving water and waste water

• Low energy consumption

• No material contact (no stress)

• Easily integrated into new and existing machine concepts

Save up to

• 70% of water

• 65% of chemistry

• 80% drying energy

Eliminate

• Tailing

• Center-side-variation

• Long downtimes

• Both side application if needed

Reduce

• PCF

• Material stress

Raise

• Line speed

• Machine uptime

• Profitability

Experience the "Innovation at work.” - In the in-house WEKO pilot lane, many trials outside of the running production chain can be tested in advance in order to guarantee customers the greatest possible flexibility and to enable their own test series outside of the production.

Together to a more sustainable textile industry!

Comments