Technology can help the intimate apparel industry become more sustainable and profitable. An excellent example is the way companies are using 3D virtual sampling to reduce waste, water usage, production times, and costs.

One of the most exciting technologies in the fashion and intimate apparel industries is 3D virtual sampling which allows the creativity of designers to be unleashed. Although the development of this technology began several years ago, it is finally getting the attention it deserves not only for its ability to bring more personalisation to the end user, but also as a way to reduce the amount of harmful waste produced, shorten production times, and lower costs.

Ultimately, every company has to reflect on its commitment to sustainability and make necessary adjustments internally to ensure success. For those companies, such as Dora L International that act as partners to intimate apparel brands and the messengers of new ideas and innovations to our clients, it is up to us to embrace practices that are good for the environment and our clients' bottom-line.

The time is now

We believe that it is time to move past the "think about it stage" and actively use this new sampling know-how as a step closer to a cleaner industry. Over the last few years, this technology has improved to a point where it allows brands and their partners to flourish. In a way, it is no longer the technology itself that is the innovation, but our ability as industry partners to leverage its benefits. Several years ago, when the capabilities were first being talked about, it seemed unreal. Then we began to see how it was being used for various types of apparel, including t-shirts, which are one dimensional and made for a good testing ground. Today, the technology and the people who have been trained on various systems have matured, allowing companies to fully embrace all of the positive aspects of virtual sampling.

A focus on the benefits

We are embracing 3D sampling as a way to reduce pot dying, lower the amount of material wastage with less printing needed, including screens cut and dye stuff for printed meeting samples. Virtual sampling allows us to curtail the amount of manual sampling required for production and helps reduce excessive material waste and water. A great deal of traditional product design and sampling requires trial and error which has led to a tradition of excess. Instead of increasing demands on workers and faster shipping, we can now focus on efforts that are more expedient and sustainable.

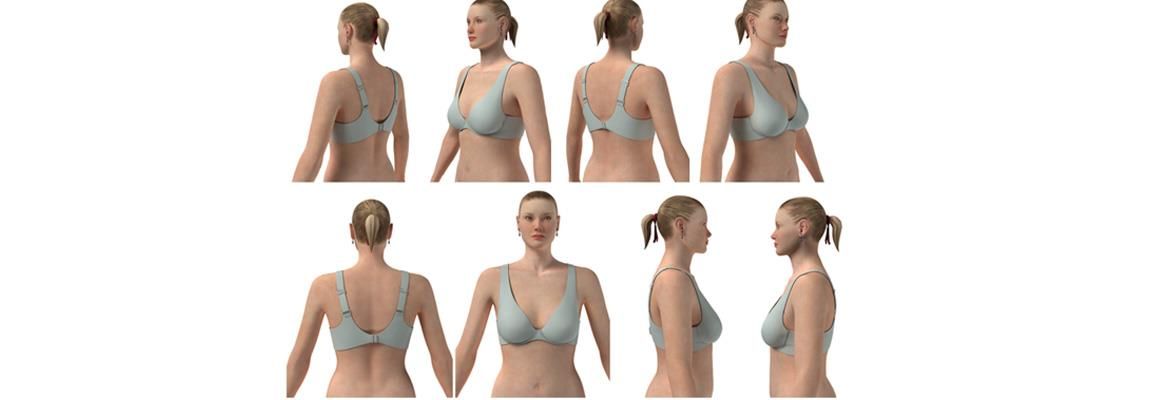

While we are embracing this new format, it is important to understand the limitations. Clients truly experience a 3D view of the garment design and can download brand avatars to see garment proportions. We can certainly view initial prototype style lines before sampling; however, we cannot actually fit garments for first prototypes. The industry is moving in this direction, but it's not there yet.

Faster turn-around times

The process of traditional sampling can take an extensive amount of time due to a variety of factors, from the need to adjust designs before the final is approved to the location of the brand versus the production team. We have become more agile and make decisions faster resulting in a shorter timeline, which is especially important when brands make changes and need to see the results quickly. Simplifying the sampling process by using 3D virtual technology results in quicker delivery times, reduction in the industry's waste, and enhanced client satisfaction.

The development period is shortened by real-time collaboration using technologies that do not require actual shipment or extensive waiting periods. In addition, 3D virtual sampling gives clients the opportunity to see correct colours and prints more quickly in a multi-dimensional format rather than the flat CAD designs. And as competition in the intimate apparel industry increases, brands and retailers are demanding reduced lead times which we can now implement.

In addition, DLI has accelerated turn-around times with its global teams that use the time differences to an advantage. We also hire experts with a lifetime of experience who are able to identify potential challenges in a design and make adjustments early on.

Focused on the future

The intimate apparel industry needs to keep innovating and adopting technologies that offer solutions to help clients become more sustainable in their product offerings. We need to use technologies, such as 3D virtual sampling, to create a new movement that focuses on the tremendous benefits for our clients, our companies, the end consumer, and the earth. Our industry contributes significantly to the national economies of many countries, employing millions and creating vital opportunities for growth. A sustainable future is essential for a positive outcome. Nevertheless, technology will not develop itself. It is up to us to make the change happen.

Comments