The presence of foreign matter in yarn and fabric remains one of the most vexatious quality challenges a textile mill faces. An impurity that creeps in in the fibre stage can create a series of problems at every further processing stage. Only a small amount of foreign matter can impact a large quantity of fabric. That is why spinning mills try to remove foreign parts as early as possible during the fibre preparation stage. The automatic detection and ejection of foreign parts has been steadily evolving over the last decades. However, it remains especially difficult to detect foreign parts that are transparent or thin, white, or thread-shaped. The Truetzschler T-SCAN TS-T5 meets these and other detection requirements with an unprecedented quality.

Truetzschler T-SCAN TS-T5

T-SCAN modules

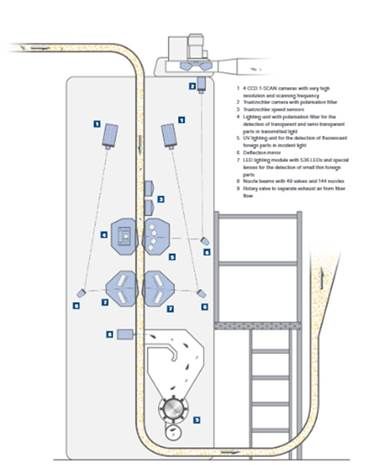

Truetzschler uses five modules for the detection of foreign parts. Each one is specialised to reliably detect various foreign parts in the fast fibre flow. The reliable detection of foreign parts provides the basis for reaching an extremely high separation rate of foreign parts in the downstream process and simultaneously preventing the separation of too many good fibres. This unique Truetzschler technology makes the T-SCAN TS-T5 essential for the quality formation in the blow room.

Module Type of foreign part detection

• F-module Coloured/dark foreign parts

• P-module Transparent foreign parts

• UV-module Fluorescent foreign parts

• G-module Shiny foreign parts

• LED-lighting Small/thin foreign parts

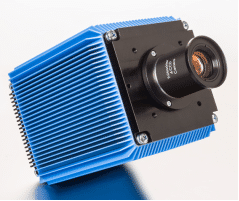

In addition to colour, 4-CCD T-SCAN cameras can also detect shininess.

Truetzschler T-SCAN TS-T5

T-SCAN modules

F-module detects coloured parts (1)

Truetzschler uses internally developed T-SCAN cameras with high resolution and scanning rates. The flow of cotton tufts is continuously monitored from both sides with reliable detection of even small coloured foreign parts.

G-module detects shiny parts (2)

Many foreign parts show no contrast to cotton, but they reflect light because they are shiny. The Truetzschler gloss module uses this effect. Two T-SCAN cameras detect parts from two sides that differ in their shininess from cotton. To detect smallest shiny foreign parts, this module works at high resolution and scanning frequency.

P-module detects transparent and semi-transparent parts (3)

The Truetzschler P-module detects transparent and semi-transparent parts, regardless of their colour. To achieve this, the patented method uses polarised transmitted light. If the cotton contains transilluminable foils, packaging residues from PP fabric and similar parts, they are reliably detected by this module.

UV-module detects fluorescent parts (4)

Some cotton sources contain foreign parts that have a fluorescent glow in UV light. Even parts that are difficult to detect, e.g. bleached cotton, PES or fluorescent PP strips, are reliably detected by the Truetzschler UV-module.

LED lighting detects thin, thread-shaped parts (5)

After a few months - invisible to the eye - the fluorescent tubes of common foreign part separators lose the light's important proportion of blue, which is crucial for colour detection of foreign parts. By contrast, 1,072 high-performance LEDs with just as many focused lenses work in the T-SCAN TS-T5. The high light intensity allows the use of cameras featuring increased resolution and scanning frequency. To ensure that the light intensity is maintained in the long run, it is monitored and independently readjusted.

Self-optimisation with embedded image processing technology

The machine control performs a number of optimisation functions on request or permanently:

•Balancing of white reference value

•Detection of cotton colour and colour variations

•Permanent consideration of current material speed

•Stop and go detection in feeding and corresponding adjustment

Intelligent waste prevention

Cotton tufts of different colour, trash, stem parts or leaf fragments are also foreign parts. These, of course, are detected as well. However, waste prevention optimisation eliminates high separation rates. It is better and safer to remove such parts on the card. A separation on the T-SCAN would result in unnecessary fibre loss. Naturally, the separating sensitivity can be adapted to the cotton quality.

The separation of such parts should be handled by the card

Reduced loss of good fibres and lower air requirement

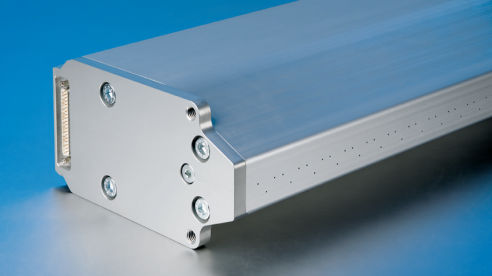

The controlled flow in the flat and wide fibre channel distributes the tufts evenly over the width. The selective response of one of the 48 valves ensures that only a minimum number of good fibres is separated. Compared to other systems, this results in annual material savings of ₹15,00,000-₹37,00,000.

The permanent speed measurement of the tuft flow also makes it possible to reduce the response time of the nozzles to a minimum. As a result, the compressed air requirement is only approx. 20 per cent of that of other systems.

The nozzle beam with 144 tiny nozzles

Reducing cleaning to a minimum

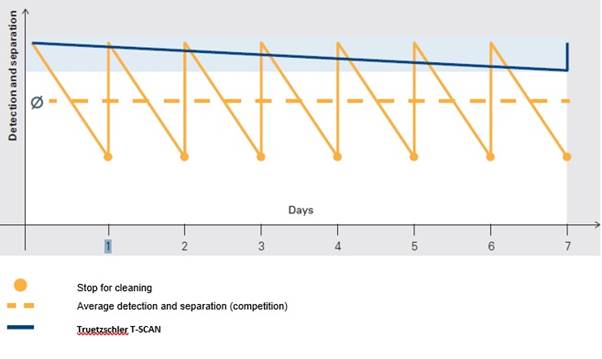

The Truetzschler T-SCAN is very effectively sealed against penetration of dust. Compared to other systems, it requires substantially less cleaning. Thus, downtimes are reduced by more than 80 per cent.

Minimal maintenance

Standard fluorescent tubes permanently lose their intensity in the blue light range. They must be replaced approx. after 6 months, otherwise the separation effectiveness declines. The Truetzschler LED module with 2x536 LEDs is monitored and readjusted as needed. This self-optimisation function ensures a constant light intensity.

Every downtime means a production loss and a restart of blow room and cards. The Truetzschler T-SCAN runs for approx. one week without having to be cleaned. Other systems must be cleaned daily or sometimes even once per shift. Due to the increasing contamination, their separation effectiveness declines as well.

Comments