If you want to kit parts in-house rather than outsourcing to a third party, then you will need the right equipment to do this.

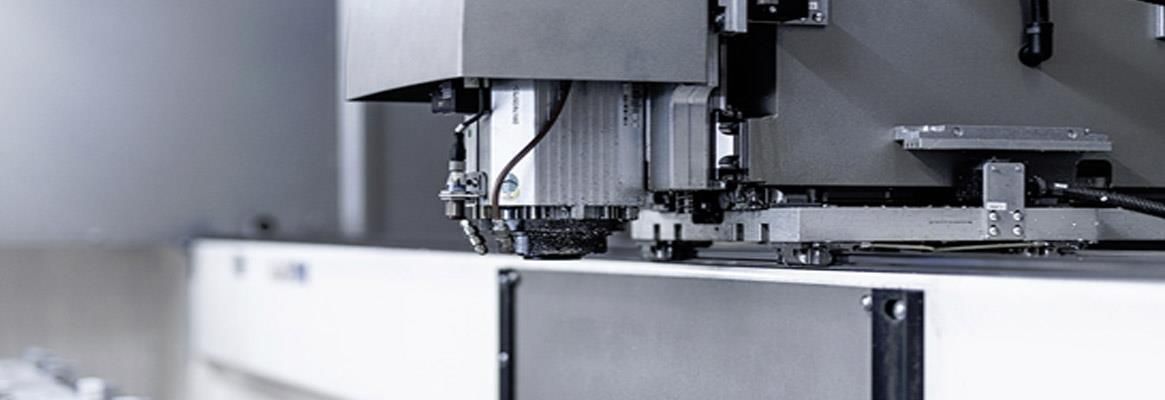

Luckily there are a host of CNC-based options out there, using computerisation to catalyse this aspect of the production process. Here are just a few reasons why buying used CNC kitting machinery is a sensible strategy for your business to pursue.

Secondhand equipment is surprisingly affordable

If you have been put off by the potentially steep costs of procuring a brand new CNC gear in the past, then you might be shocked to see just how comparatively inexpensive the used equivalents can be.

You can look for affordable options online and benefit from the same perks and features that you would expect from an unused machine, all at a lower price point.

Ofcourse there are additional considerations to take onboard when scouring the secondhand CNC equipment market, such as the state of repair and wear and tear exhibited by a prospective purchase. Even so, if your budget is limited and you are still eager to take kitting in-house, then this could provide you with the right kind of incentive to do so.

Efficiency improvements will justify your investment

Even with the aforementioned affordability of the equipment itself, you might still be hesitant to invest unless you are fully aware of the improvements to efficiency that can come from dealing with your kitting requirements internally.

Being able to accelerate your manufacturing capabilities will allow you to increase output, meet spikes in demand and generally enable you to cut out a lot of the steps which might otherwise have slowed down your mission-critical operations.

That is not to say that you will not encounter some teething troubles as you make the switch, but rather that you have to look to the long term and calculate what savings will be made over the months and years to come. Having this data to hand will enable you to make an informed decision about which CNC solution is going to deliver the most value.

Automation will give you more control and make your resources go further

Even secondhand CNC machinery will be capable of automating a whole host of important processes, which will free you up to focus your resources on other tasks and also put you in the driving seat when it comes to orchestrating how kitting and the wider manufacturing process is carried out, in addition to reducing waste.

This will also mean that you are no longer attached to any outside organisation, and are thus free of any of the uncertainty and expense that can come from this state of affairs.

So there you have it; in-house kitting with the aid of second hand CNC gear could be the answer you are looking for if your organisation is craving cost-savings and efficiency improvements. All it takes is a little research and preparation to make the most out of such a setup.

Comments