Fashion’s impact on environment keeps growing in proportion to the increase in the number of fashion pieces manufactured, requiring companies to address this issue. Focusing on five of the top fashion companies that are headquartered in different countries, this article explores if fashion sustainability is just hype or an effective action-on-ground.

Over the past few decades, fashion market has expanded multi-fold, fuelled by demand for low-cost fast fashion. The production of fast fashion, for that matter fashion of any kind, has environmental and social cost attached to it which people generally ignore while adorning fashion products. While it is now an open secret that the impacts of fashion industry in terms of pollution, water use, and carbon emissions are increasing regularly, the need for sustainable fashion is evidently growing too. Fashion is not just an aspiration anymore. It has evolved into a major economic force worth $2.5 trillion employing over 75 million people worldwide. It is estimated that clothing production has doubled between 2000 and 2014 with McKinsey also reporting in 2016 that people bought 60 per cent more garments during the same period. It then needs no brainer to realise the fact that with growing production of fashion its impact on environment and society is also growing proportionately, raising a need for addressing the concern. This feature does exactly that by discussing sustainability efforts of few of top fashion companies originating from diverse nations.

OVS S.P.A.

OVS S.p.A. (OVS) is a leading group in Italy in the clothing market for the women, men and children’s segments. Established within the Coin Group in 1972, the OVS brand gradually expanded its network and by 2020, it achieved 94 per cent brand awareness in the Italian market. OVS share in Italy’s clothing market stands at 8.4 per cent and in the children’s market it has over 20 per cent share. The Group OVS S.p.A. along with its subsidiary companies manages the network of stores (mainly in franchising) and controls product development and manufacturing operations. OVS operates through its own sales network and digital channels throughout Italy and in some foreign countries with stores of different dimensions and different management methods (direct sales or franchising); proprietary websites integrated with the physical network; and marketplaces with which it collaborates, especially abroad.

Based on the goals achieved in 2021, OVS was rated among the top performers in the industry in terms of ESG (Environmental, Social and Governance) by the most highly respected sustainability rating agencies. During 2020, OVS joined the Circular Fashion Partnership for the purpose of advancing the transition to a circular fashion system and to concretely promote the distribution of practices in the supply chain associated with a better environmental and economic impact. The Group’s sustainability strategy is based on four pillars: products and supply chain, people, customers and stores. OVS has laid down specific targets and development plans for each of these pillars.

Products And Supply Chain

85 per cent of the Group’s cotton used in the 2020 collection was either certified organic or made through the Better Cotton Initiative, thereby setting a target of 100 per cent usage in 2021. During the same year, 1.3 million items were made using recycled polyester while 30 per cent of denim was made using waterless technology – a benchmark that is now targeted to achieve 100 per cent mark by 2025. This will translate into water savings of over 1 billion litres. Overall, more than 65 per cent of the Group’s collection is made with the material from certified supply chains with reduced environmental impact. This is expected to exceed 95 per cent by 2025. In order to achieve these goals, OVS is working with suppliers who share in this vision and are participating actively in the Sustainable Apparel Coalition. It also monitors supplier performance through the Higg platform that replaced its internal audit process. The monitoring process now covers 80 per cent of the production volume setting a projection of 100 per cent by 2022.

A few years ago, OVS extended its sustainability considerations to household products as well. The primary focus is on selecting low-footprint materials. In particular, in its ‘Eco’ by Croff collection the organic cotton is used for bath sponges and table textiles recycled down for bed accessories; recycled and non-coloured glass for the table (glasses and bottles) and bathroom accessories; and recycled aluminium from cans for pots and pans, and bamboo for containers. In addition, there are purposeful efforts to eliminate plastic from OVS packaging completely by 2025 – a year which is targeted to see paper or recycled plastic packaging replacing plastic.

Denim – A Special Mention

The growing demand for denim with “distressed” look results in consumption of more water in textile factories besides increasing the amount of chemicals, especially potassium permanganate (KMnO₄) which is used to achieve “distressed” look and consequently dispersed. Since the chemical is neither sustainable for environment nor safe for factory workers, OVS has started to renew its machinery and processes to apply the most advanced standards to completely eliminate the use of KMnO₄ thereby reducing the negative footprint of denim garments. The amount of water used in denim fabric production has also been significantly reduced through a low ratio dyeing process and the application of the most advanced environmental standards such as rainwater harvesting and high-efficiency water treatment plants that ensure 80 per cent total water reuse.

People

Paying special attention to the protection of human rights in the supply chain, OVS, in November 2021, partnered with an organisation that campaigns on specific issues and intervenes urgently to resolve violations in the textile industry in production countries. Training was delivered to more than 100 employees including product managers, sourcing managers, etc on labour law and international supply chains to raise awareness of the conditions and challenges faced in production countries. Furthermore, OVS has launched a car-pooling platform for employees in order to reduce greenhouse gas emissions associated with people commuting to work. Micro-filtered water dispensers are installed, and employees given water bottles to reduce waste generated by single-use plastic bottles by around 60 per cent, saving over a tonne of CO2 as well. The ‘Health and Wellness Package’ of OVS aims to promote knowledge on self-care and well-being among employees within the company including essential topics of first-aid at home, nutrition, smoking and its impact on health, and concentration exercises. The OVS office is completely smoke-free zone as no smoking is allowed indoors as well as on the external company premises. Between 2021 and 2023, the Group implemented policies to reduce the ‘gender pay gap’ to eliminate any discrimination arising out of any difference in pay between genders.

Customers

Since OVS enjoys a vast network that reaches millions of customers, especially families, it is in a position to guide cultural change and encourage consumers to make more informed choices. This empowers OVS to make its customers aware of the environmental footprint of the clothes that they buy so that they can make informed choices. For this reason, it has created, together with the University of Padua, the ECO VALORE index. ECO VALORE is actually composed of three indices. The first measures the amount of water used to produce the item. The second measures the CO2 emissions generated by production. The third indicates how recyclable an item is. By combining these three data, OVS offers a description of the sustainability of the item. This makes OVS one of the first fashion companies in the world to make this information public.

Stores

The OVS stores equally contribute to the Group’s environmental cause. The choice of fittings and fixtures in OVS stores is consistent with the Group’s product guidelines. More sustainable materials like FSC (Forest Stewardship Council) certified wood and recycled metals are used that are easier to recycle at the end of their useful life. Stores also use energy-efficient electricity from renewable sources.

H&M

One of the world’s largest fashion groups, Sweden’s Hennes & Mauritz (H&M), is setting examples in showcasing its sustainability initiatives. Last year H&M Group, for the first time, integrated its annual and sustainability reports. During the year, the group made progress in key areas such as material sourcing, inclusion and diversity, and circular design. It partnered with others to test and scale circular materials, processes and business models, and to progress social protection and dialogue within its supply chain.

In 2021, the H&M Foundation launched a new planet strategy — Planet Positive. The strategy addresses challenges within the entire earth system including climate, water, ocean, biodiversity and land. The Foundation invests in new research and supports innovations with a planet positive focus. One example is its five-year ‘Planet First’ partnership with the Hong Kong Research Institute of Textiles and Apparel (HKRITA), which aims to consider all aspects of earth’s natural support systems.

Climate Positive Approach

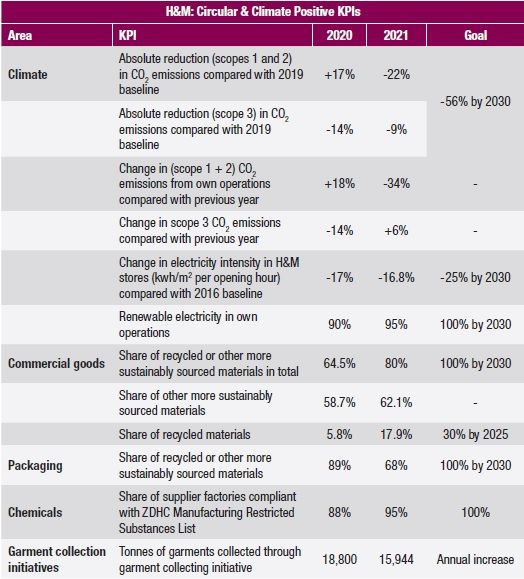

H&M aims to achieve net-zero CO2e emissions by 2040, taking a climate positive approach and having a net positive impact on biodiversity by being circular throughout the business. In 2021, H&M set up new CO2e emissions reduction goals to support its net-zero and climate positive ambitions. Compared to 2019 baseline, the group was able to reduce its absolute Scope 1 and 2 emissions by 22 per cent and its Scope 3 emissions by 9 per cent. It also reduced production water use by 6.6 per cent. Additionally, H&M engaged with the Science Based Targets Network to begin developing targets for nature and invested in projects focused on reducing the biodiversity impact of its material sourcing. The company also continued its work with WWF to set context specific (contextual) water targets and to develop the new 2030 Water Strategy.

Circularity

H&M Group is transitioning to a circular ecosystem, transforming how the company designs and creates its products and systems, works with suppliers and partners, and interacts with customers. It focuses on three interconnected areas in this regard – ‘Circular Products’ which involves creation of long-lasting products made from safe, recycled and sustainably sourced material; ‘Circular Supply Chains’ – the systems that circulate products and support circular production processes and material flows; and ‘Circular Customer Journeys’ providing accessible ways to experience and engage in circular fashion where products are used more, repaired, reused and recycled. In 2021, H&M tripled the volume of recycled materials used in its garments and confirmed the ambition for all its products to be designed for circularity by 2025, supported by its new circular design tool ‘Circulator’. A blueprint for a circular fashion industry within planetary boundaries was launched too. It is the product of a three-year research by the Stockholm Resilience Centre together with the Ellen MacArthur Foundation, funded by H&M Group.

Checking Hazardous Chemicals

H&M has Chemical Management Roadmap to achieve zero discharge of hazardous chemicals and 100 per cent safe and traceable chemicals. The company is a member of the Apparel and Footwear International RSL Management (AFIRM) Group, Zero Discharge of Hazardous Chemicals (ZDHC) and ChemSec Business Group. It follows the AFIRM Restricted Substances List and the ZDHC Manufacturing Restricted Substances List 2.0 (MRSL), as well as the ZDHC Wastewater Guidelines and Chemical Management System. H&M Group Chemical Restrictions is committed to phasing out additional potentially harmful substances. Therefore, it uses the Screened Chemistry hazard-based scoring system – a third-party toxicological assessment, to identify safer chemicals.

Educating Customers

To maximise product life and scale circular business models via circular customer journey, H&M focuses on three levers – ‘Use & Care’ under which customers are encouraged to love their fashion items for longer period and extend the life of their fashion favourites through care and repair initiatives; ‘Access’ by offering a diverse range of access models through which customers can enjoy and experience fashion while keeping products in circulation; and, finally ‘Collect’ that supports customers to access services to donate pre-loved products so they can be reused, remade, or recycled. In 2021, H&M’s ‘Take Care’ initiative continued to offer customers in 46 markets ways to care, repair and customise their clothing.

Gildan

Gildan is Canadian apparel manufacturing company based out of Montreal. The company is the world’s largest vertically-integrated manufacturer of apparel and specialises in selling its products in bulk to printers, brands or companies who then choose to decorate them as they see fit. More than 90 per cent of the company’s total revenue is generated from the products that are manufactured in its own factories – a big reason to be sustainability-conscious. Gildan’s sustainability journey started earlier than most, with an already 20-year track record of implementing, measuring, monitoring, optimising, and reporting in this regard.

During 2021, the company undertook a detailed assessment to redefine its ESG strategy going forward and push its sustainability approach even further, taking into account new technologies and advances in the industry. On January 17, 2022, the company announced its Next Generation ESG Strategy and future targets with the commitment of making meaningful advancements by 2030 in key ESG areas. The company’s Next Generation ESG strategy focuses on initiatives towards reducing its Scope 1 and 2 GHG (Greenhouse Gas) emissions in line with the Science Based Targets initiative (SBTi), reducing water intensity (a reduction in water usage/withdrawal per kilogram produced), circularity and sourcing sustainable raw materials, increasing community investment, strengthening diversity, equity, and inclusion by setting a first-time goal on gender parity, and implementing a disclosure plan to gradually further align to the Task Force on Climate-related Financial Disclosures (TCFD) recommendations. Gildan fosters a circular economy to reduce its environmental impact and intends to source more sustainable and transparent raw materials and enhance sustainable waste management initiatives.

Reduce, Recycle, And Reuse

Working on its agenda of circularity Gildan reduces, reuses, and recycles materials, as well as uses more sustainable materials. Gildan recycles 100 per cent of its textile clippings. The company uses 3D computer modelling to share product designs with its customers. This allows the customer to see the design and make changes based on the computer model rather than on a physical prototype or sample of the actual garment which would need to be manufactured and shipped to them. By using computer modelling, resource consumption of raw materials, energy, water, and waste is reduced. There is a heightened focus on sourcing sustainable raw materials and enhancing sustainable waste management initiatives. The company has set clear targets in this direction – source 30 per cent recycled polyester or alternative fibres and yarns by 2027; use 75 per cent recycled or sustainable packaging and trim materials by 2027; and reduce Scope 1 and 2 GHG emissions by 30 per cent.

Sustainable Materials

Gildan develops its yarns, fabrics, and garments with sustainable and responsible design in mind while also ensuring that the materials meet the quality standards and cost expectations of the customers. In addition, it continuously seeks out opportunities to use recycled and/or more sustainable materials in both apparel and its packaging. It also reuses materials whenever possible. In fact, 100 per cent of Gildan’s fabric cutting scraps are recycled into fibre and used in new products, such as textiles, socks, industrial materials, and mops. The company is targeting to source 100 per cent sustainable cotton by 2025. Additionally, to validate sustainability in its supply chain, Gildan is working to obtain ISO 45001 certification for 100 per cent of owned and operated factories by 2028.

Operational Waste Management

In addition to its Global Environment and Energy Policy and EMS (Environmental Management Systems), the company’s approach to waste management is guided by the General Solid Waste Management Procedure. At some of its facilities, the Zero Discharge Hazardous Chemicals (ZDHC) guidelines are strictly followed, with 84 per cent of total Gildan waste being either recycled or repurposed. The company strives to minimise waste in how it sources, manufactures, and packages its apparel. To do this, Gildan collaborates with its customers, suppliers, and NGOs to move towards a more circular model to keep waste out of landfills. Between 2015 and 2020, 371,745 tonnes of waste were recycled and diverted from landfill. To further reduce waste sent to landfill, in 2020, the company began transitioning its sewing threads and materials used for labels to recycle polyester while also evaluating options to use 100 per cent recycled materials for twill tape, zippers, buttons, and draw cords. The options to create 100 per cent sustainable products made from 50 per cent recycled polyester and 50 per cent regenerated cotton, are also being explored. The efforts are on to achieve zero manufacturing waste by 2027.

Transparency

Gildan believes in enhancing and strengthening its ESG (Environmental, Social & Governance) disclosures in order to provide all stakeholders with robust, transparent, and decision-useful information. The company was ranked 25th out of 250 global brands on the 2020 Fashion Transparency Index. In 2021, Gildan continued reporting under SASB (Sustainability Accounting Standards Board), continued its TCFD journey and redefined its ESG strategy and working on achieving the new targets. In the first half of 2021, it officially joined the U.S. Cotton Trust Protocol which aims to increase supply of sustainably-grown cotton; 90 per cent of Gildan cotton is sourced from the US. At the same time, Gildan’s Social and Sustainable Compliance Guidebook outlines its approach with respect to increasing supply chain transparency and build capacity among Gildan suppliers in order to improve labour conditions. In the current year, Gildan is planning to further enhance alignment to the TCFD framework through a subsequent disclosure in a stand-alone report, which will detail Gildan’s climate-related governance, strategy, risk management and metrics, and targets.

Climate, Energy & Water

Gildan fights against climate change by paving the way towards a low carbon future. Its goal of reducing Scope 1 and 2 GHG emissions by 30 per cent by 2030 are aligned with the SBTi and the level of decarbonisation required, meeting the goals of the Paris Agreement. To that effect, Gildan has signed the SBTi commitment letter, joining companies worldwide in following a science-based approach in reducing carbon emissions. The manufacturing company is also committed to addressing water related risks linked to climate change. As such, Gildan plans to further invest in water efficiency and implement additional water reducing, reusing, and recycling options in its operations with the goal to reduce water intensity (usage/withdrawal per kilogram produced) by 20 per cent (against 2018 baseline) by 2030. C&A

C&A

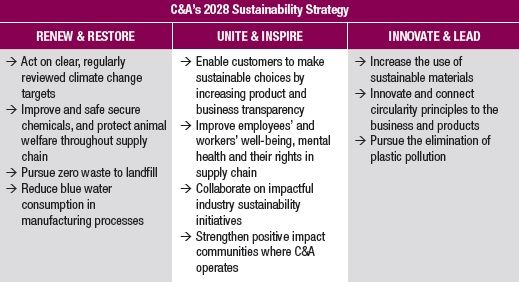

C&A, with a 180-year-old history, is an international Dutch chain of fashion retail clothing stores that proudly claims sustainability in its DNA. The C&A brand, present in four retail markets – Europe, Brazil, Mexico and China, has adopted a powerful ‘Wear the change’ phrase for sustainability which helps it create local customisation across all four markets, connecting customers and inspiring them to make sustainable choices. Already, over half of its collections are more sustainable including bio-cotton, recycled materials or Cradle-to-Cradle certified fabric. In C&A stores and its online presence too, the company makes and provides sustainable choices. C&A global sustainability team collaborates with its retail market teams to develop locally relevant plans that take the group closer towards its 2028 goals. C&A is signatory to the UNGC and UN SDGs which provide frameworks and guidance for advancing its sustainability agenda that encompasses its three actionable areas – sustainable products, sustainable supply and sustainable lives.

Sustainable Products

C&A defines its ‘more’ sustainable cotton as either sourced as certified organic cotton (Organic Content Standard, OCS or Global Organic Textile Standard, GOTS), Better Cotton, recycled cotton or transitional cotton which is produced by farmers during the time of conversion to organic certification, usually over three years. Since 2016, C&A has steadily increased the use of more sustainable cotton from 53 per cent in 2016 to 96 per cent in 2020. Part of this growth came due to its switch in 2015 from the sustainable cotton programme REEL to Better Cotton under the Better Cotton Initiative (BCI) which leads the industry in improving global cotton production. C&A has developed sources of more sustainable cotton by building relationship with farmers and farm groups trained by BCI in sustainable cotton farming practices. In some cases, C&A helps to facilitate the transition to organic farming. While only 1 per cent of the cotton produced in the world is estimated to be organic, 40 per cent of the cotton in C&A products is organic. C&A Europe market achieved targeted 100 per cent share of ‘more’ sustainable cotton in 2020; Brazil gained 92 per cent from 80 per cent in previous year against the same target; and achievements in Mexico and China markets remained at 50 per cent and 85 per cent, respectively.

While many of its efforts have been in the direction to improve the sustainability of cotton, C&A also works to identify the environmental impacts of viscose and polyester. Since 2018, it has been using Canopy Style’s Hot Button Report, the primary fibre sourcing analysis tool for the fashion industry, to inform its viscose sourcing. C&A has sourced 100 per cent of man-made cellulosics for C&A Europe and China markets from producers with the highest ‘green shirt’ ranking in the report and with annual audits confirming low risk of sourcing from the world’s ‘Ancient and Endangered Forests’ and other controversial sources.

In 2020, C&A met and exceeded its goal, using 68 per cent more sustainable raw materials. This was achieved owing to a substantial increase in recycled polyester content. By mid-2021, the chain of custody and traceability in man-made cellulosics was also increased to ensure sourcing of these materials only from Birla and Lenzing – suppliers providing more sustainable responsible cellulose.

C&A promoted circular fashion as well when it launched innovative denim collection made with the first-ever

Platinum level Cradle to Cradle certified fabric. Featuring 100 per cent rapidly renewable resources and fully recyclable, the small collection included denim jackets, trousers, and shirts. Woven tops were also developed made with 100 per cent Cradle to Cradle certified fabric.

Sustainable Supply

C&A has Sustainable Chemicals Management Programme (SCM) to control hazardous chemicals across the supply chain. The programme represents a holistic chemical management approach which includes input, process, and output management. The objective of input management is for C&A suppliers to procure chemicals that meet Zero Discharge of Hazardous Chemicals (ZDHC) requirements. Process management ensures each supply chain partner has the personnel, management systems, tools, and expertise to meet ZDHC requirements. For output management, the regular testing at suppliers’ production units is conducted against the ZDHC Foundation Wastewater Guidelines to ensure clean water discharge. In 2018, after conducting a pilot project a year earlier, C&A rolled out ‘Clean Chain’ tool to increase the transparency of the chemicals used in its supply chain, allowing it to determine which chemical products are being used, who is supplying them, and in what quantities. This tool provides information that drives the adoption of safer chemistry. C&A phased out its internal audit system in March 2019 in favour of the Higg 3.0 FEM industry standard, which links manufacturers, brands, and retailers together in measuring environmental impacts, and provides various training and improvement resources.

These developments allowed C&A to streamline the rollout of its SCM programme which began in 2016 with 50 fabric mills and more facilities were slowly added over the following years. In 2017, only 29 per cent of facilities were meeting C&A’s requirements while the remaining facilities were given a clear timeframe for raising their performance to continue working with the company. By 2018, the astonishing results were out when the company had more than 300 production units covered globally under the SCM programme, including all major fabric mills, laundries, printers, and vertical set-ups in the C&A supply chain. By the end of 2019, 93 per cent of facilities were meeting the requirements. However, due to severe mobility restrictions imposed in all countries during pandemic, the SCM programme had to be paused until July 2020.

When it comes to evaluating suppliers on sustainability, C&A’s guiding principle is transparency supported by capacity building. Each supplier’s production unit is rated on a scale from A to E, with A being the highest rating. Production units with no serious violations are rated A and B. C&A has set an aspirational goal of sourcing 100 per cent of its product volume from these suppliers only. However, between 2016 and 2019, the sourcing from A- and B-rated suppliers decreased from 78 per cent to 52 per cent, and then increased to 65 per cent in 2020. The main reason for the overall decrease from 2016 to 2020 was the significant increase in stringency level for social and labour standards. The year 2020 also saw a shift in C&A’s supplier monitoring programme away from its proprietary auditing protocols to an industry-wide approach that is becoming widely adopted — the Social and Labour Convergence Project (SLCP) Converged Assessment Framework (CAF).

PVH Corp.

PVH Corp. from the US is one the world’s largest and most admired fashion companies which connects consumers in over 40 countries. It owns renowned brands Calvin Klein (CK), Tommy Hilfiger and Heritage brands. The US fashion Group adopts ‘Forward Fashion’ strategy that aims to reduce its negative impacts to zero, positive impacts to 100 per cent and improve over 1 million lives throughout its value chain encompassing its associates and supply chain workers, their families and their communities. PVH’s sustainability can be seen-in-action through its two iconic brands – CK and Tommy.

CK

The 50-year-old brand works to be more inclusive, equitable, innovative and circular through action across its entire business including product, workplace, supply chain, partnerships and communities. In 2020, CK Europe more than doubled (21 per cent) the use of sustainable materials from the previous year (10 per cent) though in contribution terms it remained relatively lower than what other fashion players have achieved. In CK Jeans, the same year, the lower-impact denim finishing technique significantly reduced CK’s freshwater consumption and carbon emissions compared to conventional techniques. Lower impact washes typically have 50 per cent reduction in water use and 30 per cent reduction in energy usage compared to conventional washes.

The fashion company introduced ‘The Eco Series’ across a number of product categories including jeans, sportswear and performance. These programmes featured the brand’s most iconic silhouettes reissued with sustainable attributes including more sustainable cotton, recycled materials and natural dyes. Not just those, CK One recycle programme also introduced fabric from recycled plastic water bottles. The programme introduced the use of ‘repreve’ fabric made from recycled plastic water bottles for men’s and womens’ underwear. It also prioritised the use of innovative recycled materials in swimwear, leveraging textiles made from pre- and post-consumer waste such as ‘repreve’ and ECONYL. In 2020, 55 per cent of CK swimwear offering was made from recycled materials. Moving into 2021, many of the swim programmes featured 100 per cent recycled materials.

Tommy Hilfiger

Another of PVH’s 35-year-old iconic brand Tommy Hilfiger is fully aware of the biggest challenges faced by the world today – from climate change and natural resources scarcity to racism and inequality. At the same time the American fashion brand acknowledges the reality that no single fashion company can change all of this. However, individual participation in global efforts can surely bring the desired change. At individual level, Tommy believes change can only be brought by the way it works and the clothes its consumers wear via ‘stitch-by-stitch, person-by-person and innovation-by-innovation’ approach. Driven by this philosophy the brand has made considerable progress on its sustainability journey over the last decade and looks forward to accelerating it over the coming years guided by the urge to create a fashion that ‘Wastes Nothing and Welcomes All’. August 2020 onwards, it has accelerated its commitments with focus on social and environmental sustainability. Working with more than 100 associates globally Tommy has identified 24 initial targets inclusive of the 15 ‘Forward Fashion’ targets towards 2030. The targets are focused on four pillars: Circle Round, Made for Life, Everyone Welcome and Opportunity for All. Guided by its Rolling Innovation Plan, the brand keeps reviewing and assessing where it stands, pivoting along the way, adjusting targets and doing everything it can to create the sustainable fashion.

A year and a half back, it launched its first circular business model ‘Tommy for Life’ in The Netherlands. Under this model, the brand took back items from consumers as well as damaged pieces from its stores or online operations, then cleaned, repaired and resold them prolonging product use. Through this process the brand was able to divert 36,429 kilos of textile waste in The Netherlands keeping the expansion plan for 2021 in tow.

Like many other brands in the industry, Tommy Hilfiger also focuses on denim to drive transformative change through sustainable innovations. Ninety per cent of Tommy’s global denim is more sustainable and 2.1 million pieces were produced in 2020 containing 20 per cent post-consumer recycled cotton. Another means of driving change undertaken by the brand is the circular innovation as demonstrated by Tommy’s Ellen MacArthur Foundation (EMF) Jeans Redesign collection, created with circular design principles like detachable buttons and the replacement of metal rivets.

Wrap up

The fashion companies are doing what they are supposed to do by law and CSR dictates, but sustainable fashion is still a long road to travel. As long as the companies are guided by revenue growth pressure instead of prioritising resilience to save and protect planet, its inhabitants and their well-being, the so-called eco-fashion will remain a mirage.

Comments