Jute is a type of bast fibre plant that is used as an affordable natural fibre source for many human purposes. It is also known as the ‘Golden Fibre’ due to its shiny appearance.

The capacity of jute to be utilised either alone or in a variety of blends with other fibres and materials is its most significant characteristic. Jute is mainly used to make sacks and cloth for wrapping bales of cotton, as containers for growing young plant, in the production of pulp and paper, many household products and nonwoven textiles. Its antistatic properties and low thermal conductivity comprise a great characteristic that could be turned to useful products.

Properties of Jute

• Commercial jute varies vary from brown to off-white in colour.

• Fibres are easily damaged by strong alkalis and acids.

• Resistant to bleaching agents.

• The colour of the fibre changes slightly under sunlight, due to the presence of lignin in the fibre.

• Prevention ability of mildew is better than cotton and linen.

• It is easy to dye jute fibre and basic dyes are used for dyeing.

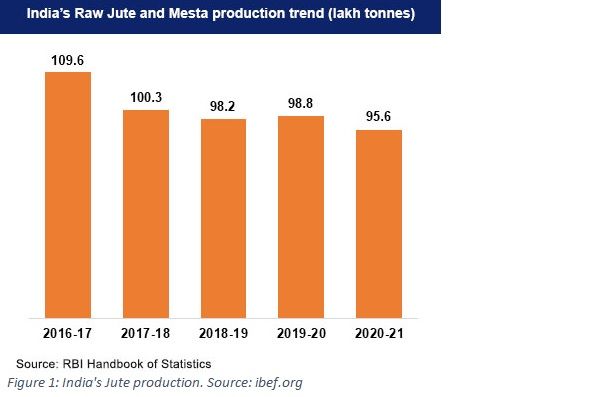

Jute Production in India

West Bengal, Orissa, Assam, Bihar, and Andhra Pradesh are the major jute-producing states in India. However, large number of jute mills are located in West Bengal, so it is the place where Indian Jute sector is highly depended on.

Due to the significant local market demand, 90 per cent of the total production of jute is often used domestically. In FY22, India’s production of jute goods stood at 1,080 lakh tonnes.

Over time, jute and jute products from India have seen tremendous increase in exports. The total amount of jute exports increased at a CAGR of 9 per cent between 2015-16 and 2020-21.

India exports jute and jute products mainly to the US, the UK, Australia, Belgium, Egypt, Germany, Italy, Japan, Saudi Arabia, and Turkey. United States was the leading importer of jute products from India during 2021-22, followed by the UK and Germany. The export value of jute products has been increasing from 2018 to July 2022, and is expected to continue the same trend in the future.

Global Jute Production

According to National Jute Board, India is the top jute producing country followed by Bangladesh, China, and Thailand. In 2021, the top exporters of jute and other textile fibres were Bangladesh ($161M), India ($33.4M), Tanzania, Belgium, and Germany. In 2021, the top importers of jute and other textile fibres were Pakistan ($58.3M), India ($49.4M), Nepal, China, and Netherlands.

Government Support for Jute Industry

The Indian government has set up two major governing bodies for the jute sector: National Jute Board and Jute Product Development & Export Promotion Council (JPDEPC). Further, the National Jute Board has initiated a number of programmes and schemes to improve and promote the jute sector in India. These include Improved Cultivations and Retting Exercises (ICARE), Jute Product Diversification Scheme (JPDs), Jute Resource-Cum Production Centre (JRCPC) and Jute Retail Outlet scheme.

What is Jute Mark India?

The government has introduced certification of authenticity in April 2023 for jute products named “Jute Mark India”. It is an initiative to promote and protect Indian jute products that assure the collective identity and assurance on origin and quality for traditional jute and jute products. The certification is anticipated to grow India’s domestic market and jute product exports. Customers can learn more about the producer by scanning the exclusive QR code found on each Jute Mark label.

Innovations in Jute Industry:

• Influence of jute fibre on concrete properties: To boost strength and other qualities required in the building business, scientists used a variety of fibres in concrete to build blocks. According to the study, adding enough jute to concrete could increase its toughness, ductility, flexural strength, tensile strength, compressive strength, and fracture mechanism. Additionally, it has been suggested that adding jute to concrete could increase earthquake resilience too.

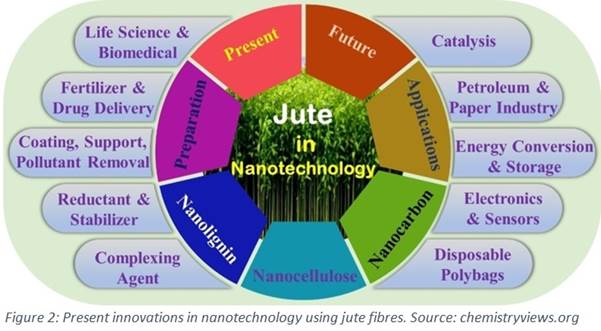

• Use of nano-technology in jute processing: Jute fibres are being processed using nanotechnology to increase their durability, tensile strength, and moisture resistance (Fig.2).

• Creation of high-value products from jute fibres: Jute fibres are being used to create high-value products like textiles, carpets, and even automobile interiors. These products are not only durable but also have a unique natural texture that makes them aesthetically pleasing.

Conclusion

India has competitive advantage in the jute industry due to a combination of factors such as abundant availability of raw jute which makes the supply easier, large scale of production that enables to achieve the economies of scale in production, large pool of skilled and semi-skilled labour in the jute sector, and various incentives and schemes initiated by the government to support the industry. Comparing the Indian jute industry with that of other countries, these same factors provide advantage to the jute sector for future development and research, that can make the industry an effective competitor in the global market.

20240830145908.gif)

Comments