The LYCRA Company innovates and produces fibre and technology solutions for the apparel and personal care industries. Headquartered in Wilmington, Delaware, The LYCRA Company is recognised worldwide for its innovative products, technical expertise, sustainable solutions, and unmatched marketing support. Commercial Director South Asia and EMEA Fabrizio Maggi talks about the global textile industry, innovation, digital transformation, and the company’s focus on the South Asian region.

1. From your perspective, how has the global textile industry evolved over the past decade, and what have been the key drivers of these changes?

Sustainability, the rise of athleisure, the body positivity movement, digitalisation, and social media are just some of the developments that have impacted the textile industry in the past decade.

With growing awareness of the effects that the apparel industry has on our planet, consumers are much more selective and conscious about their apparel purchases. They want products that last, made with recycled or renewable materials to reduce their carbon footprint, and are demanding a higher level of transparency from the brands and retailers that they purchase from. This has resulted in an increased focus on sustainable practices across the industry as brands and retailers design garments for longer wear life and experiment with new business models like garment resale platforms.

The rise of athleisure, fuelled by the increase in people working from home during and post- pandemic, has resulted in a major shift in the casualisation of fashion. Consumers want garments that are not only comfortable but enable them to move freely throughout their day. In addition, they value performance benefits like warming and cooling technologies that enhance the functionality of their garments.

The body positivity movement has also been transformative across the world of fashion, celebrating and embracing all body types, sizes, physical abilities, races, and genders.

The pandemic led to a rapid digital transformation across the entire apparel value chain, with the adoption of various digital technologies and advancements that are reshaping how products are made and sold.

Influencer marketing across social media platforms has emerged as an effective and, oftentimes, efficient way for new and established brands to gain traction in a highly competitive marketplace.

2. As the issue of sustainability becomes more critical, how do you think the textile industry needs to adapt and what role will technology play in this transformation?

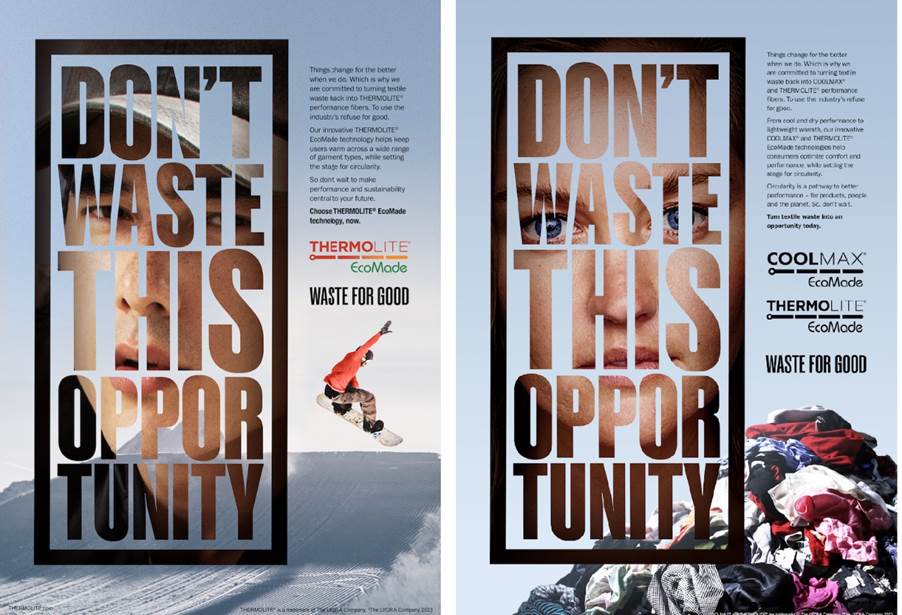

All of us in the industry need to take a holistic approach to more sustainable production and consumption. We must significantly reduce our use of finite resources, replace them with renewables, design products for durability, and then at the end of life, ensure those products can be recycled. Technology has a huge role to play in making this happen, from technologies to make lower impact, bio-derived fibres to those that can advance garment sorting and recycling technologies on a broad scale. These are just a few examples of the types of challenges that technology can help address.

3. In your opinion, what is the future of the textile industry in a post-pandemic world? How can businesses prepare for and adapt to this future?

The ways in which consumers behave and shop have fundamentally changed in the pandemic as we are seeing a greater value placed on sustainability, comfort, and performance features of garments. We are well-positioned to address these megatrends with our portfolio of differentiated fibre solutions.

In addition, the retail sector has reached an inflection point as more and more brands are setting ambitious sustainability goals and tapping into their strategic suppliers, like The LYCRA Company, to provide sustainable solutions that support a more circular economy. Brands and retailers understand that tackling this challenge will be a collective effort across the value chain, and our track record in delivering innovative solutions to this industry is quite compelling. We are focused on doing our part to help advance the circular economy with products like COOLMAX® EcoMade and THERMOLITE® EcoMade technologies made from 100 per cent recycled textile waste.

4. What are the major challenges currently facing the global textile industry, and how might companies overcome these challenges?

Global Inflationary pressures including rising energy costs, geopolitical tensions, climate crises, and weakened consumer demand are weighing heavily on the global economy and likewise the textile industry. Cautiousness and agility are key as it is important to ensure you have the right strategies in place to navigate through these challenging times while still investing to drive innovation and product differentiation.

5. Could you share your insights on the impact of digital transformation on the textile industry and how it is changing the way companies operate?

The ongoing advancements and adoptions of technology, coupled with consumer acceptance and usage of multiple digital platforms, continue to transform how brands go to market. And the pandemic has only accelerated these trends.

Our own digital transformation resulted in our launch of the LYCRA ONE™ marketplace, which provides our mill partners with another sales channel of qualified leads sourcing certified fabrics powered by our technologies. It is also the place for our customers to find insights into trends, download assets, order hangtags and more.

6. How has your understanding of the textile industry evolved since you joined The LYCRA Company, especially given its unique product offerings?

Since I joined the business over 18 years ago, the textile industry has undergone significant changes and evolution from Sustainability and Eco-Friendly Practices to Digitalisation and Technology to Smart Textiles/Wearable Technology, just to name a few.

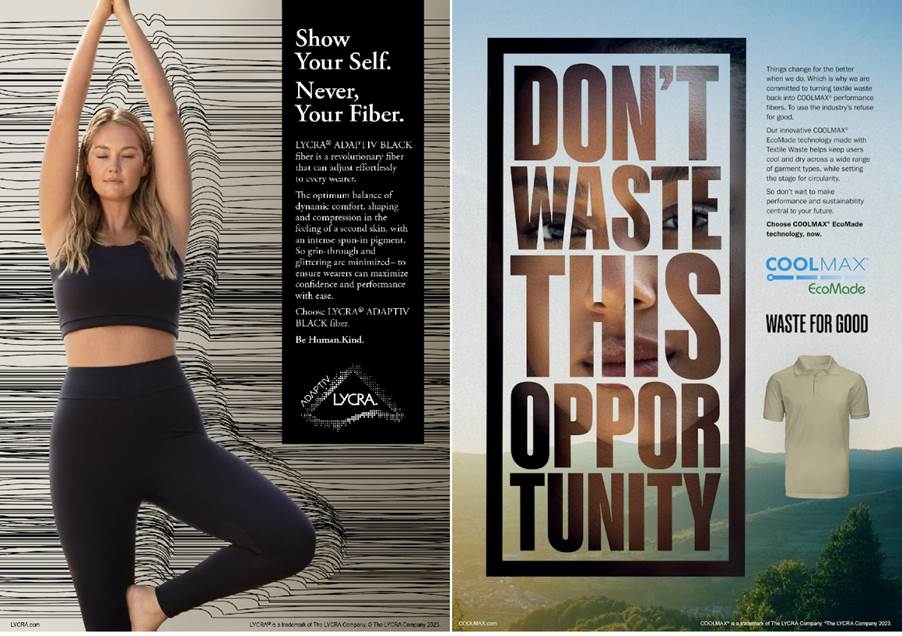

As the originator of elastane fibre, The LYCRA Company has and will continue to be well positioned to capitalise on the trends that influence the market. Over the years, LYCRA® fibre has played a key role in helping to transform many garment categories from super stretch denim, anti-laddering hosiery, leggings, swimwear, shapewear and more, and we continue to innovate new fibre solutions that meet the changing needs of consumers while delivering on our company purpose to enhance everyday life.

7. Can you discuss a few key trends shaping the textile and fabric industry in the South Asian region?

South Asia export, particularly countries like Pakistan, India, and Bangladesh, has been increasingly recognised as a global textile and apparel manufacturing hub. The region’s export-oriented textile industry has continued to grow, with a focus on supplying international markets. South Asian textile manufacturers have made significant strides in improving the quality of their products. This has led to a reputation for producing high-quality textiles and apparel, which is crucial for maintaining competitiveness in the global market.

A notable trend in the South Asian textile industry is the move towards vertical integration. Textile mills are increasingly looking to control various stages of the production process, from raw materials to finished products. This vertical integration helps shorten the value chain, reduce lead times, and respond more swiftly to market demands.

In the domestic market, South Asian consumers, particularly in India, have become more discerning. They are seeking better quality, functional, and sophisticated apparel options. This shift in consumer preferences has encouraged textile manufacturers to diversify their product offerings and invest in R&D to meet these demands.

Talking about South Asia, we should not forget to mention the Indian domestic market, which has become more organised. Modern retail formats, shopping malls, and e-commerce platforms have gained popularity. This has led to changes in supply chain dynamics and marketing strategies for textile companies targeting domestic consumers.

South Asian textile manufacturers have also made efforts to adopt sustainable practices, including eco-friendly production processes and the use of sustainable materials to meet the demands of environmentally conscious consumers.

These trends reflect the ongoing evolution of the textile and fabric industry in South Asia, where a combination of export orientation, quality improvement, vertical integration, changing consumer preferences, and market organisation are driving key developments.

8. Given the diversity of markets in the South Asia and other regions, how do you balance standardisation with the need for customisation in terms of products and marketing strategies?

Our Product Development team works closely with our regional mill customers to examine an innovation’s potential for commercialisation, including the need for any local adaptions to the fibre properties.

We also invest in regionalised marketing efforts to connect at both the customer and consumer levels. Such activities include trade media, trade shows, hangtags, collateral etc. Customised co-marketing programmes specific to the region(s) enable compelling storytelling to differentiate and drive sales of our customers’ offerings that include our branded fibres.

9. The LYCRA Company is known for its innovative products. How do you ensure that innovation is continuously driving commercial strategies within your region?

Innovation has always been at the core of who we are as a company. Our technologies have been the catalyst behind many key innovations and transformations in the industry. We continue to challenge ourselves to drive further product differentiation that helps to redefine the markets we compete in. Gathering insights into fast-changing consumer needs and expectations, we specifically look for pain points that can be solved with new or improved products or processes that add value.

We recently launched LYCRA® lastingFIT 2.0 technology for the Denim/Wovens segment, a key innovation in our LYCRA® XTRA LIFE™ brand portfolio. In response to the consumer desire for garments that last and are sustainable, this new technology helps create durable garments with long-lasting fit and comfort, delivering elevated functionality using recycled content (50 per cent recycled PET bottles).

To meet the market’s need for durable apparel offering more inclusive sizing, enhanced comfort and greater functionality, we also expanded our LYCRA® ADAPTIV fibre portfolio to include two new fibres: LYCRA® ADAPTIV BLACK fibre and LYCRA® ADAPTIV XTRA LIFE fibre.

10. The LYCRA Company emphasises sustainability as a key part of its business philosophy. Can you share some initiatives or strategies that have been implemented in the South Asian region to align with this philosophy?

Last year, we announced our 2030 Sustainability Goals for the company and each of our sites has been working towards achieving those goals. One of our goals is to significantly reduce our Scope 2 emissions (those from purchased electricity) by converting sites responsible for 80 per cent of our emissions to renewable energy by 2025 and 100 per cent by 2030. Towards this end, we converted the purchased electricity at our Maydown, Northern Ireland site to renewables through the use of Energy Attribution Certificates, reducing our Scope 2 emissions globally by 23 per cent.

Another area is ensuring that we continue to be a fair and ethical employer and a good steward of the environment. In 2022, for the second year in a row, our Tuas plant in Singapore completed the Higg Facilities Social and Labor module, again scoring in the upper quartile. They also self-certified on the Higg Facilities Environmental Module (FEM) and this year will have their scores third-party verified.

11. How has digital transformation influenced your company’s operations and how have you incorporated these changes into your commercial strategy?

The expansion of our digital infrastructure enables new forms of virtual engagement and demonstrates the differentiation and sources of innovation — including sustainable innovation — that we are helping bring to our customers across the value chain.

LYCRA ONE™ Marketplace is an online platform connecting brands, retailers, and garment makers to a global network of partner mills in a virtual capacity. This digital B2B platform enables us to showcase our products and services more holistically.

Our partnership with Browzwear, the industry’s leading 3D software for apparel design and development, enables new forms of engagement with our global customer base, and demonstrates the differentiation and sources of innovation that The LYCRA Company is helping bring to its customers across the apparel value chain. With Browzwear's technology, designers can create digital garments that incorporate fabrics that feature our fibres. This streamlines the production process and reduces the need to manufacture samples, saving time and reducing waste for more efficient and sustainable operations.

12. Can you share some of the keyways in which The LYCRA Company engages with its partners and customers in the South Asian region to maintain strong relationships?

The LYCRA Company maintains strong relationships with its partners and customers in the South Asian region through a range of strategic initiatives and collaborations, engaging with all stakeholders across the textile value chain. This includes working closely with yarn manufacturers, fabric mills, garment makers, and brands and retailers. This comprehensive approach allows to offer integrated solutions that meet the needs of the entire industry.

We at The LYCRA Company collaborate with global brands and retailers to understand their specific requirements and challenges. As well, we are engaged with Indian domestic brands, as we recognise the importance of catering to local markets and ensuring that our solutions align with the preferences and requirements of domestic consumers.

The LYCRA Company provides support to mills to develop and promote fabrics and garments using our fibres and technologies, and we assist brands and retailers in promoting and communicating the features and benefits of garments made with our fibres. This may involve marketing campaigns, consumer education, and branding initiatives to highlight the enhanced comfort, fit, and performance that our fibres bring to apparel.

Engaging with partners and customers at multiple levels of the value chain helps to maintain strong and enduring relationships, ultimately benefiting both the industry and consumers.

13. As we look to the future, what is your vision for The LYCRA Company in South Asia? How do you plan to achieve this vision?

South Asia is the right place to put our focus in the future, as this region is becoming more and more the focal point for the global apparel industry. The India domestic market as well is becoming important for The LYCRA Company and our technologies.

Our vision for growth in South Asia is centred on what sets us apart – from other elastane competitors and most textile companies – namely our brand franchises (LYCRA®, COOLMAX® and THERMOLITE®), unique innovations, and a network of value-chain partners from fabric mills to retailers. The collective value of these assets and capabilities, which is amplified today with sustainability and digitalisation, truly puts us in a great competitive position to be successful in South Asia and beyond.

_Big.jpg)

Comments