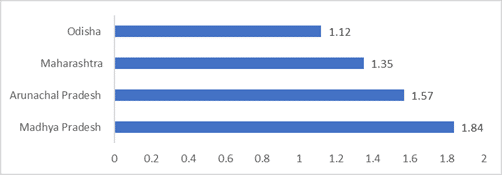

Fibre derived from bamboo can be used to make textiles. The bamboo plant, which is highly beneficial for the environment, does not require any toxic fertiliser for its growth and replenishment. It is highly rainfed and is free of all the pests which can potentially affect the health of the plant. In India, the total bamboo bearing area is 15 million hectare and Madhya Pradesh has the highest bearing area for bamboo of 1.84 million hectare.

Figure 1: Highest Bamboo Bearing States by Area (in million ha)

Source: State of the Forest Report 2021

Bamboo in Textiles

The fibres extracted from the plant are used in the production of blankets, towels, etc. As per a life cycle analysis by the Council of Fashion Designers of India, the cultivation of bamboo is environmentally friendly, but the process of extracting fibre from the stem of the plant takes a lot of chemical processing, which in turn increases the risk of water eutrophication. On the other hand, the process of converting these fibres into yarn is typically manual, which helps mitigate some of the environmental impact. Nevertheless, concerns remain regarding other aspects of bamboo textile production, such as removing the natural golden colour of bamboo and the use of softeners, dyes, bleaches, and other finishing processes, which can also contribute to environmental harm.

Policies by the Government of India to Promote Bamboo

Fabrics that are created from bamboo are included under the value addition and product development of the National Bamboo Mission (NBM), which was subsumed under the Mission for Development of Horticulture in 2014. Now value addition, product development, skill development and research and development have been included under the National Mission for Sustainable Agriculture.

As of 2021, the government has approved 11 industrial and processing units for the creation of fabric and jewellery of bamboo. There are projects in the pipeline to promote the plantation of bamboo in the northeastern area along with the assistance to create a value chain out of the same in those states. The Japan-India Northeast Bamboo Development Initiative includes innovation and design for jewellery, handicrafts, creation of fabrics, research and development and capacity building.

Under the initiative of NBM, the fabric and fibre extraction projects are getting a subsidy from the government, with 10 per cent of additional assistance for the northeastern states. The government under this scheme is promoting the creation of logistics for storing purposes, promotion of the rural haats and the bamboo bazaar etc. So, if the policy is properly implemented, the bamboo fibre and fabric industry will flourish, creating yet an another sustainable and environmentally friendly alternative to produce textiles in a sustainable manner.

Half Sustainable, Half Worrisome

Although bamboo is considered to be environment friendly and sustainable, the final product however does not have 100 per cent bamboo, and it can be way more harmful than the original product. The final rayon only has 10 per cent of bamboo content, according to the CDFA materials index. With a significant difference between bamboo rayon and the natural bast bamboo fibre, it is always suggested to buy bamboo lyocell as it is more of a sustainable alternative and follows a closed-loop process.

Certifications for Buying Bamboo Products

A host of different certifications are available to ensure the consumed bamboo product is processed in an environmentally friendly manner:

-

Forest Stewardship Council: The not-for-profit organisation has different certifications based on the kind of sustainability measures a commodity follows. The certification involves the saving of the livelihoods of people involved while ensuring that the environment is protected. Another certification involves whether the materials are properly certified and segregated from the other non-sustainable means before they actually make their way to the supply chain.

-

Verified Carbon Standard (VCS): It is one of the most commonly used certifications for a product to be certified minimum greenhouse gas emitter. Therefore, the current certification encourages the carbon sequestration through the agriculture, forestation, and other land use (AFOLU). The current certification encourages to reduce the carbon emissions by successfully adopting strategies aimed at reducing the de-forestation and carbon emissions.

-

OEKO-TEX: This certification checks if the produced textiles products are free from any toxic chemicals and dyes. The certification has 4 product categories, with the intensity of the certification’s standards increasing based on the level of skin contact of the product. The more direct the skin contact, the stricter and more rigorous the requirements.

Future Potential

Going forward, the outlook for bamboo’s use in the textile industry looks promising, particularly as a sustainable alternative to conventional fabrics. Its rapid growth rate and minimal need for pesticides make it an eco-friendly crop. Bamboo fibres, known for their softness and breathability, are increasingly becoming popular in producing a variety of clothing and home textiles. The industry is also exploring more environmentally friendly methods to process bamboo into fibre, aiming to reduce chemical use and water pollution. With growing consumer awareness and demand for sustainable products, bamboo’s role in textiles is expected to expand, potentially leading to innovations in fabric technology and more widespread adoption in fashion and home furnishings. This shift towards bamboo could significantly contribute to reducing the environmental footprint of the textile industry.

Comments