The Internet of Things (IoT) refers to the network of physical devices, vehicles, home appliances, and other items that are embedded with sensors, software, and connectivity, allowing them to collect and exchange data. The implementation of IoT in the textile industry has opened new opportunities for product development, production efficiency, supply chain management, and sustainability. The uses of IoT in the textile industry are diverse and rapidly evolving, from smart fabrics that can monitor temperature and moisture to supply chain management tools that track products throughout the production and delivery process. IoT sensors can be embedded in textiles at various stages of production, from raw materials to finished products, enabling real-time data collection and analysis to optimise product performance, reduce waste, and improve sustainability.

In recent years, the implementation of IoT in the textile industry has gained momentum, with companies investing in research and development to create new products that incorporate IoT. For example, wearable technology has become increasingly popular, with companies developing smart clothing that can monitor vital signs and track fitness activities. IoT sensors can be used to monitor various aspects of textile production, such as temperature, humidity, and chemical levels, enabling real-time data collection and analysis. This allows for better quality control and can help identify issues before they become major problems. For monitoring the production processes, enabling real-time data collection and analysis can help identify areas where production can be improved, reducing waste, and increasing efficiency.

Smart textiles that incorporate IoT sensors can be used to monitor vital signs, track fitness activities, and monitor environmental factors such as temperature and humidity. Tracking the textile products throughout the supply chain can help identify issues with delivery and provide valuable data to improve supply chain management. The integration of IoT in the textile industry is a key component of Industry 4.0, which refers to the fourth industrial revolution that is characterised by the integration of digital and physical systems. IoT is being used to optimise textile production, improve quality control, and reduce costs.

The implementation of IoT in the textile industry is transforming the way products are developed, produced, and managed, and has the potential to drive innovation and improve sustainability across the industry. As the technology continues to evolve, it will be exciting to see how IoT will continue to shape the future of the textile industry.

Basic Concept

The basic concept of IoT is to connect everyday physical objects to the internet and enable them to communicate with each other and with humans, gathering and sharing data to improve efficiency, convenience, and productivity. This is achieved by embedding sensors, actuators, and other electronic devices in these objects, which are then interconnected using wired or wireless networks, and can be remotely monitored and controlled via software applications.

The application of IoT in textiles, also known as ‘Smart Textiles’, includes:

- Wearable Technology: IoT-enabled textiles can be integrated with wearable devices, such as fitness trackers and smartwatches, to monitor biometric data, track physical activity, and provide personalised coaching.

- Smart Clothing: IoT-enabled clothing can be embedded with sensors to monitor body temperature, heart rate, and other physiological metrics. This can be useful in healthcare and sports settings.

- Textile Manufacturing: IoT can be used to monitor the production process in textile manufacturing, providing real-time data on machine performance, energy consumption, and quality control.

- Supply Chain Management: IoT can be used to track textile products through the supply chain, providing real-time visibility on inventory, transportation, and delivery.

- Textile Recycling: IoT can be used to monitor textile waste and improve the efficiency of recycling processes.

- Smart Fabrics: IoT-enabled textiles can be embedded with sensors, actuators, and other electronic components to provide advanced functionalities, such as self-healing, self-cleaning, and colour-changing properties. This can lead to innovative new textile products for various applications.

Challenges and Opportunities

Challenges

- Integration: IoT requires the integration of various technologies, which can be challenging in the textile industry due to the complex nature of textile products.

- Standardisation: Lack of standardisation can pose a challenge in the development and implementation of IoT-enabled textile products.

- Privacy and Security: IoT devices can collect and transmit sensitive data, which requires robust security measures to prevent data breaches and protect the privacy of individuals.

- Power and Battery Life: IoT devices require power to operate, and textile products may not have access to a reliable power source. This can lead to challenges in developing IoT-enabled textiles that have long battery life.

- Cost: IoT devices and sensors can be expensive, which can increase the cost of producing IoT-enabled textiles.

Opportunities

- Innovation: IoT presents an opportunity for innovation in the textile industry by creating new products with advanced functionalities.

- Efficiency: IoT-enabled textiles can improve the efficiency of production, logistics, and supply chain management.

- Personalisation: IoT can enable the production of personalised textile products based on individual needs and preferences.

- Sustainability: IoT can help in promoting sustainability in the textile industry by enabling efficient recycling and reducing waste.

- Improved User Experience: IoT can enhance the user experience of textile products by providing real-time data and personalised functionalities.

Implementation

Below is a general overview of the steps involved in implementing IoT in a textile product, but the actual implementation process will depend on the specific application and the available resources.

- Identify Opportunities: The first step is to identify the areas in the textile industry where IoT can be applied, such as supply chain management, manufacturing, and product development.

- Develop a Strategy: Once the opportunities are identified, a strategy should be developed that outlines the goals, budget, timeline, and resources required for implementing IoT.

- Select IoT Technology: Next, the appropriate IoT technology should be selected, which could include sensors, smart fabrics, wearables, and software platforms.

- Integration: The IoT technology needs to be integrated with the textile products and processes. This could involve retrofitting existing machinery, embedding sensors in textiles, and connecting devices to networks.

- Data Management: IoT devices generate vast amounts of data, which needs to be managed efficiently. This could involve implementing data analytics tools and data visualisation dashboards to extract insights from the data.

- Testing and Optimisation: Once the IoT technology is implemented, it should be tested and optimised to ensure that it meets the desired goals and performs effectively.

- Continuous Improvement: IoT implementation is an ongoing process that requires continuous improvement and monitoring. This could involve updating the technology, refining the strategy, and identifying new opportunities for IoT in the textile industry.

IoT Components in Smart Textiles

The mechanism of IoT in smart textiles involves the integration of these components to create a ‘smart’ textile that can collect, process, and transmit data, and respond to environmental and physiological changes in real-time. This can lead to a range of new functionalities and applications, such as wearable health monitoring, sports performance tracking, and interactive fashion design.

- Sensors: Smart textiles are embedded with various types of sensors, such as temperature sensors, humidity sensors, and

- pressure sensors. These sensors collect data from the environment and from the wearer’s body.

- Actuators: Smart textiles can also include actuators, which can respond to the data collected by sensors. Examples of actuators include motors, pumps, and electro-active polymers.

- Microcontrollers: Microcontrollers are used to process the data collected by sensors and actuators. They are the ‘brain’ of the smart textile, and they can execute algorithms to make decisions based on the data collected.

- Wireless Connectivity: Smart textiles need to be connected to the internet to enable data transfer and communication with other devices. This is typically achieved using wireless protocols such as Wi-Fi, Bluetooth, or Zigbee.

- Cloud Computing: The data collected by smart textiles is usually stored and processed in the cloud. Cloud computing enables real-time data analysis and provides insights into the performance of the smart textile.

- Mobile Apps: Smart textiles can be controlled and monitored using mobile apps. These apps enable the user to interact with the smart textile, adjust settings, and receive alerts.

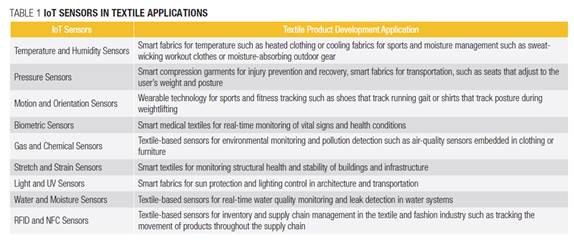

Table 1 shows some examples of IoT sensors and their applications in textile product development.

Latest Developments

There are several recent developments in textiles (including technical textiles) using IoT that have the potential to transform various industries. Here are a few examples:

- Smart Garments for Athletes: Several companies have developed smart garments that can monitor an athlete’s heart rate, breathing, and other physiological data, providing real-time feedback on performance and injury prevention. These garments are made possible by embedding sensors and microprocessors into the fabric.

- IoT-Enabled Industrial Textiles: In the industrial sector, IoT-enabled textiles are being used to monitor and optimise various processes. For example, textiles embedded with sensors can be used to monitor the temperature and humidity in a manufacturing plant, enabling real-time adjustments to maintain optimal conditions.

- Biomedical Textiles for Wound Care: IoT is being used to develop biomedical textiles for wound care. These textiles can be embedded with sensors that monitor the wound’s healing progress and automatically dispense medication or other treatment as needed.

- Smart Fabrics for Transportation: Smart fabrics are being developed for use in transportation, such as cars and airplanes. These fabrics can be embedded with sensors that monitor temperature, humidity, and pressure, providing real-time data that can be used to optimise the vehicle’s performance and safety.

- Environmental Monitoring with Textile Sensors: IoT is being used to develop textile-based sensors that can monitor the environment for pollutants, temperature, and humidity. These sensors can be integrated into clothing, furniture, or other textile products, providing real-time data that can be used for environmental monitoring and control.

Future of IoT

The future of IoT in textiles and technical textiles is expected to lead to new functionalities, improved efficiency, and enhanced sustainability, making it an exciting and rapidly evolving area of innovation. Some of the key areas where IoT is expected to have a significant impact include:

- Wearable Technology: IoT-enabled wearable technology is expected to revolutionise the medical and sports industries, enabling real-time health monitoring, performance tracking, and injury prevention.

- Industrial Textiles: IoT can be used to monitor and optimise industrial processes, reducing waste and improving efficiency. This could include applications such as filtration, insulation, and reinforcement.

- Smart Fabrics: IoT-enabled smart fabrics can provide a range of functionalities such as temperature regulation, UV protection, and moisture management. These fabrics could be used in a variety of applications, including clothing, architecture, and transportation.

- Structural Health Monitoring: IoT can be used to monitor the structural health of buildings, bridges, and other infrastructure by embedding sensors into textile materials.

- Environment Monitoring: IoT can be used to monitor environmental conditions such as air quality, water quality, and weather patterns, by embedding sensors into textiles.

- Biomedical Textiles: IoT can be used to develop biomedical textiles that can monitor and treat medical conditions, such as wound care, drug delivery, and tissue engineering.

Conclusion

The implementation of IoT in the textile industry has opened new opportunities for product development, production efficiency, supply chain management, and sustainability. The uses of IoT in the textile industry are diverse and rapidly evolving and have the potential to drive innovation and improve sustainability across the industry. The challenges in integrating IoT into the complex nature of textile products and the lack of standardisation can be addressed through collaboration and investment in research and development.

The integration of IoT in the textile industry is a key component of Industry 4.0, and is transforming the way products are developed, produced, and managed. As the technology continues to evolve, it will be exciting to see how IoT will continue to shape the future of the textile industry. The potential benefits of IoT in the textile industry are numerous, including improved efficiency, sustainability, and user experience. Thus, IoT is an important technology that will continue to drive innovation and improve the way people live and work.

Comments