Garment on Hanger service best suited for 'need-it-now' industries

APM Terminals Inland Services, South Asia is part of APM Terminals (part of the Maersk group), a leading global port and inland services company headquartered in The Hague. It has operations in 58 countries and has one of the world's leading global terminal networks. The company offers garment on hanger (GOH) service. GOH containers are standard dry containers converted or modified to be able to safely and conveniently carry garments on hangers-the way these are hung in major retail stores. Managing director of the South Asian arm Ajit Venkataraman discusses the length and breadth of GOH and the latest at the company.

Tell us about the Garment on Hanger (GOH) service.

APM Terminals Inland Services' GOH service enables dust-proof and hassle-free, direct-to-store delivery of retail garments in an export-import set-up. The activities that make up this service include customised fabrication of standard containers to suit the make, type, design and length of a garment; use of mobile GOH trolleys for effortless domestic and in-facility transportation and movement (ensuring safety and time saving); set up of GOH rooms ensuring safe storage of garments before being placed into containers and shipped; and skilled and efficient labour. This enables the retail store to simply pick and place the garments in the shop by removing plastic covers.

Tell us about the value-added services you offer.

Bonded and non-bonded general and specialised warehousing, including for chemicals and temperature-controlled products, palletization, packaging and labelling are just some of the value-added services we offer.

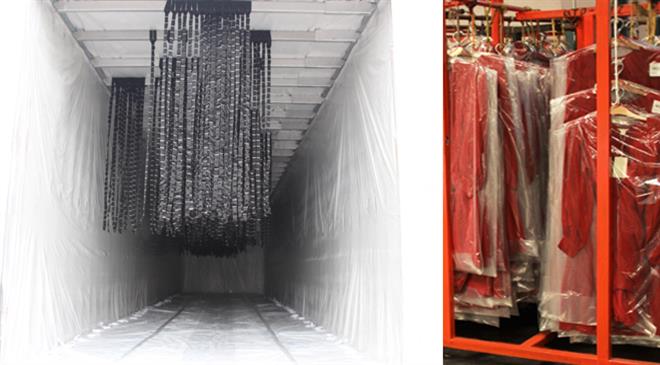

Our value-added services for GOH include development of specialised mobile hanging docks (called GOH on wheels) to enable hassle-free and safe movement of garments across the facility. These are specialised mobile rails having wheels, which can be easily moved to different locations. While stuffing the container, these mobile rails can be directly loaded inside the container. Another key value-added service includes the set-up of dedicated and customised warehouses inside the CFS for dust and moisture-free storage while ensuring safety of the garments.

What is the USP of your GOH service? How is it different or better than other players?

Apparel retail is a fashion industry and is synonymous with speed, making time a critical component. And of course, garments as a product are easily prone to damage due to moisture and dust. What sets us apart are quality, efficiency and speed.

With over two decades of lifting the apparel export-import trade for the country, we have become synonymous with expertise. We have been one of the GOH pioneers in India. Our strategically-located container services facilities in Chennai, Dadri and Nhava Sheva serve India's top three apparel manufacturing belts serving leading global apparel fashion brands.

Driven by an array of continued innovations, customised solutions and enhanced offerings, our customers have come to consider us as their go-to partners. Safety, speed, reliability and cost effectiveness backed by our long and rich experience are the hallmarks of our services.

Apart from our standard array of services, there are some innovative features that have been highly appreciated and are witnessing increased demand. Mobile GOH fabrication is a service offered in case of emergency situations, in which the fabrication service is taken at the customer's doorstep, the container fabricated, stuffed with GOH, and shipped. Another example is the concept of GOH partitions developed to jointly ship garments on GOH mobile trolleys (for low value apparel) and on beams (for high value apparel).

Quality is all pervasive in our operations. On the material side, a 28-point checklist for ensuring high quality fabrication and quality testing, such as load tests, for every single beam in the container are followed. We have highly skilled and experienced people working in this field for over 10-15 years. Our team's GOH fabrication turnaround time is within 3.5 hours against the industry standard of 5.5 to 6 hours. In today's scenario, two hours saved can make a world of difference. Managing the right load in the container, on each beam, well thought and calculated placement of loaded hangers to ensure apparel protection are just some of the many critical aspects that are well addressed.

How many racks can a container fit? How many garments in each rack are hung?

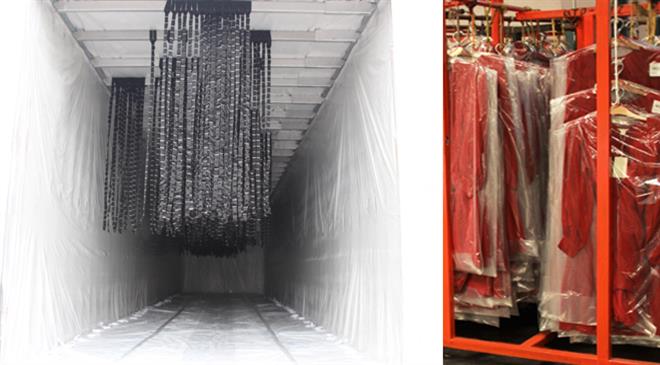

The concept of GOH is different. The count is not made in terms of racks, but hangers and loops. As against the traditional method of arranging garments in cartons and stuffing the same in containers, in the GOH system, the garments are individually placed on hangers, covered with plastic and the hangers are then hung in a specially-designed and fabricated garment holding system inside the container. This is created when an existing container is modified to have beams from which hanger holding systems are suspended. There are two such systems-strings/ropes with loops and strips with loops. The capacity always varies with the type and weight of the garment. On an average, a twenty-foot container can carry 5,000 ladies' coats.

Does the movement and handling affect the quality of the garment?

That is the very issue that this service addresses. The entire solution is designed to maintain the quality of the garments. To provide direct-to-store services, it is critical that right from its point of first movement to the destination, the garments are protected from dust, moisture, creasing and damage.

Here is how the garment moves: The garment is put on a hanger and covered top-to-down with a plastic sheet. We fabricate mobile GOH trolleys to move the garment inside our paved yard facilities and from there, to the specially constructed dust and moisture-free GOH Rooms. GOH Rooms have special lining and are structured to store the garments in the same hanging format. The access in these rooms is controlled and restricted; for example, there is special footwear to use in the room. When it is time to export the shipment, we create customised GOH containers by fabricating dry containers with hanging systems technically best suited to handle the load and the volume of GOH. These systems are then load-tested to ensure there is no overloading or mishap on the journey, for example, the garments falling off the system onto container floor. We take pride in wrinkle-free delivery to customers.

What's the annual tonnage in terms of garments that you carry, and from which geographies to which is the bulk transported?

Shipping containers are available in two sizes-twenty feet and forty feet long, known as TEUs and FEUs respectively. A standard container can generally carry 28 tonnes but given the volume and quality requirements for a garment consignment, we have observed that generally the weight is limited to 8 tonnes, including the weight of GOH fabrication. We have seen that approximately 70 per cent of retail garment exports are to the Europe, around 20 per cent to the United States and the balance 10 per cent to other regions, mainly the United Arab Emirates.

What are the advantages of using GOH over the conventional way of shipping garments?

Speed and quality are of essence in the apparel retail industry. In the conventional method, each garment is first ironed, folded, covered with plastic and then packed in a carton. These cartons are then sent to be stuffed into containers for export. Once the containers are received at the end destination, they are taken to a work area, taken out of the carton, unwrapped and unfolded, dusted if not covered in plastic properly, ironed and then taken to the retail counter or shop floor for display. In this case, even a customs inspection will entail extraction of cartons from the container, unpacking for inspection and repacking them.

In case of GOH, the garment once put on a hanger and covered with plastic, stays in the same position across oceans till it reaches the shop floor.

Thus, GOH does away with the manual activities like folding, ironing and wrapping, and adds speed to the supply chain. Additionally, with innovative customisation in fabrication like ropes and strings, GOH enables efficient use of space and process to curtail the number of hands that the garment passes through and deliver maximum number of stock keeping units (SKUs) per container. The concept of GOH rooms ensures garment safety.

The option to bring a mobile GOH unit right inside the container leads to reduction in the frequency of garment handling and reduced time for stuffing the containers. GOH also reduces cost as it does away with the cartons, speeds up the process and reduces intermediate activities like ironing of clothes before display. Additionally, since the fabrication is done in a standard container, one doesn't have to invest in dedicated containers. Due to the inherent nature and string of activities, GOH leads to reduced rejection rates at the last mile. GOH is best suited for this 'need-it-now' industry.

Does APM plan to increase its operations in India?

We are constantly looking for opportunities to best address the supply chain needs of the trade and its customers. There is special focus on unlocking the potential of Indian hinterland by bringing it closer to the coast and hence, to the world. The intent is to deliver services in sectors requiring special expertise including cold chain, chemicals and solar, to name a few. (HO)

What is the size of the apparel companies using the GOH services?

The services are beneficial to large-, mid- and even small-sized companies. Most of our clients are medium-to-large scale organisations that have complex requirements of garment transportation and storage. Quality and speed are non-negotiable for them.

What kind of garments is the service used for-menswear, womenswear or kidswear?

This service is applicable for all. The concept is about ensuring that the garments don't need to be folded, and are in a state such that when the truck arrives with the consignment at the retail store, it simply is picked up and placed in the store as it is without any unpacking, unfolding, dust vacuuming or ironing, saving time and cost. These are factors that are critical for the fast-moving fashion industry.

We have seen this is especially beneficial for long dresses, coats, jackets, blazers, kids' dresses and women's gowns that form a major proportion of garments we create GOH systems for.

How was your performance in the last two fiscal and what expectations from next two?

APM Terminals Inland Services is an end-to-end logistics solutions provider especially for export-import trade with own infrastructure of container freight stations (CFS), inland container depots (ICDs), container services facilities, warehouses and cold chain storage facilities across India. Last year has been a landmark year for our South Asian business, with an increased opportunity to provide store-door solutions to the customers and service India's high potential agriculture, seafood, pharmaceuticals and chemical industries. South India's first integrated CFS and cold chain solutions facility based in Chennai was inaugurated in 2018 and delivers services of global standards. It is already handling a variety of products from across the nation. Another recent development was the environment clearance certificate for the Pune ICD and integrated supply chain solutions facility.

Broadly, our company has performed in line with the market trend where the western and northern regions of India have seen shipment and cargo growth. Being fairly new facilities, our business in Mundra and Tuticorin has shown an impressive pick up in volumes. Pune's ICD and integrated supply chain solutions facility too is delivering on its promise of being the one-stop solution for various manufacturers in the vicinity and neighbouring regions. The receipt of authorised economic operator certification has also helped add value to the customers' supply chains.

Our container services division's performance has been significant this year, backed primarily by its leading expertise in refrigerated container maintenance and repair, and thoughtful GOH fabrication solutions.