Bagging to differ

The Association of Sarva Seva Farms (ASSEFA) was founded in 1969 as an agency to provide guidance and assistance to allottees of land under the Bhoodan Movement or "land-gift" movement launched by Gandhian Vinobha Bhave for raising agricultural production on the newly-allotted lands. Nisha Subramaniam of ASSEFA reveals to Meher Castelino the story behind Sura, which was started for the fisherwomen in Cuddalore to empower them by creating a variety of products from cotton fabrics.

Tell us about ASSEFA.

The ASSEFA (Association of Sarva Seva Farms) was started for the development of Bhoodan families. "Sarvodaya" (welfare of all) is the guiding philosophy of ASSEFA as expounded by Gandhi. All persons are equal in the social order. Sharing the produce of their labour, with the strong protecting the weak and functioning as their trustees, ASSEFA was the second phase of Bhoodan, the Gramdan movement of the 1950s which was one of the greatest socio-political movements under the leadership of Acharya Vinoba Bhave. In 1968-69, the Tamil Nadu Sarvodaya Mandal established an organisation named ASSEFA in collaboration with the Tamil Nadu Bhoodan Board and Movimento Suiluppo E Pace (MSP) to uplift the social, economic aspects of Bhoodan-Gramdan families.

In 1969, the first Sarva Seva Farm was established at Sevalur (Ramnad district) in Tamil Nadu as an experiment for the benefit of 35 Bhoodan allottees owning and managing 70 acres of farms. The efforts of S Loganathan brought success and generated enthusiasm among the people and the team of workers.

Aligned to this intention, ASSEFA has created agriculture and dairy-based communities to support the poorest of the poor. Recognising the role of education in social transformation, ASSEFA has set up over 100 schools, mostly in rural and interior Tamil Nadu, aspiring to work with schools and communities. ASSEFA has multiple projects across the following themes: health, agriculture, livestock and education.

Who designs the products? How many items are made in a month?

I did the designing initially. Gradually, when people started giving us bag samples, the ladies started to stitch them on their own. Colour combinations and design matching is done by the ladies. We have also had volunteers come in to teach the women new designs or specific aspects of value-addition for the bags. Nine months into the Sura journey, the mothers are looking forward to taking on bulk orders - beginning to explore the power of economics in transforming the reality for their children's lives.

Different categories are made every month. We are still in a start-up phase and things are very orderdriven. Our highest production was in February-March, when we made 1,300 bags.

The team will break even in a matter of 3-4 months. The investment for materials is made by a local champion as a loan to be repaid over and above a regular income for the ladies every month.

How is the marketing done? Are those available abroad? How long does it take for the products to reach the customers?

Marketing is done through Facebook, Instagram and WhatsApp, as well as word-of-mouth. Initially, the products were sold among known circles. It has been exciting to watch the customer base grow with word-of-mouth and to have customers return to buy more products. Currently, Shivaranjani and I provide support on the marketing front. We have begun computer literacy and English training programme for the ladies so that they can play a bigger role on the marketing front.

Products are only available online. We haven't set up offline spaces yet. But we do display and sell our products in stalls. We have had people fall in love with our creations and carry them abroad, although we haven't yet been able to deliver abroad through online channels.

If the number of products is less than 30, those are delivered in a week. A bulk order needs a minimum of three weeks, accounting for the designing time and contingencies such as long power cuts, lack of transport to the courier service in case of rains, which are so characteristic of work in rural India.

Where does Sura fit in?

A group of mothers in Chithiraipettai village in Cuddalore, Tamil Nadu, angry about rising education costs, wanted to spend their 7-8 hours of "leisure" time meaningfully to support their children's education. Microcredit schemes helped them buy their own sewing machines and start sewing classes. Sura was born out of the struggle to pay school fees and loans. The mothers decided to create products and sell them to cover expenses. That was the beginning in August 2017, and today, with the continued support of ASSEFA, they are designing, stitching and selling bags and generating income for their families.

What does the word Sura mean?

Sura is the Tamil word for 'shark'. Sura represents the fisherwomen community, their fighting spirit and power. The women chose to call themselves Sura to connect to where they come from-the fisherfolk community-and to their fighting spirit. Team Sura took microcredits and purchased sewing machines in July 2017. After training, the first batch of classes started right away, and the first lot of bags was sold in August last year.

What are the materials being used? Are there different styles and collections?

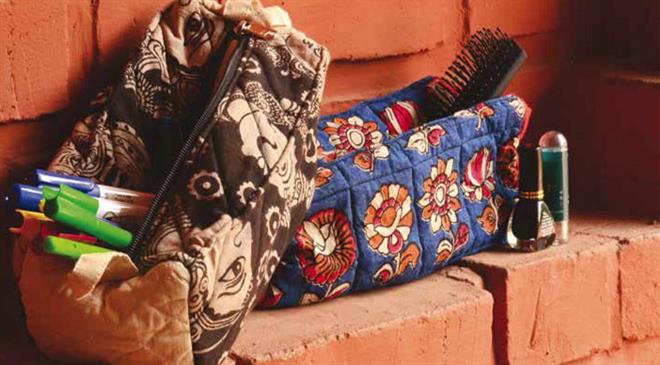

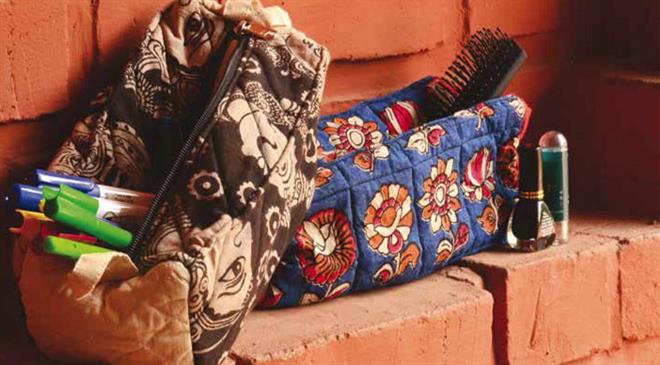

With an aim to keep our work meaningful beyond a means to financial sustainability, we have aspired to use cottons predominantly. It also helps people make a switch from plastic to cotton bags. We believe that the colours and patterns add so much value to our creations, and hence use kalamkari and ikat prints. Recently, we have been exploring denims combined with cotton kalamkari for totes.

Within the repertoire of products, some tweaks are made to jazz up creations. For instance, we started with plain bedcovers and kalamkari pillow covers. Over time, we designed a "Yin Yang series" where half the bedcover was kalamkari and the other half plain; combined with a plain pillow cover and a kalamkari pillow cover. Our people loved this series and we sold out all the bedcovers in no time.

Within shopping bags, we have created white bags with kalamkari handles, based on a conversation with a customer. Every bag of ours carries a story in itself. We are very grateful to so many people who have sat through multiple interactions to crack a product. For instance, of late we have been experimenting by creating a line of cushion covers and totes using handloom lungis-a local produce; Kurinjipadi in Cuddalore is famous for its handloom lungis.

There is a lot of competition in handmade products. How different are the Sura products?

We believe in co-existing and learning from people by creating cloth bags in particular. As competition may not take us too far (precisely given the number of units involved in handmade products), Krishnan who runs "Yellow Bags" in Madurai has been a great mentor and a thought partner in setting up Sura. We learn from mistakes, make new ones ourselves, and learn a lot from each other. Only earlier this month, the Sura team went over to Yellow Bags for an exposure visit. That said, we also keep a sharp eye on the quality consistently and are open to innovating, experimenting new styles. These two aspects of our work-we believe-will set us up for long-term success.

How does ASSEFA help in the running of Sura?

ASSEFA has provided the space for schools and communities to interact among themselves. ASSEFA also supports project directors in every region, who in turn work directly with the schools and communities.

In Cuddalore, ASSEFA supports two project directors- educator couple Nisha and Gowtham-to explore the intersection between education and livelihood across ASSEFA schools and communities. Sura is an initiative started with the Chithiraipet school and community.

Is Sura the only brand of products in fabrics, or are there others that ASSEFA has created?

ASSEFA is currently working to revive 'Karungani cotton', an indigenous variety of cotton. About 300 farmers have come together for this purpose in rural Madurai. Karungani is an indigenous cotton of Tamil Nadu, cultivated especially in the southern rain-fed districts. It has the capacity to withstand drought and shows a high level of pest resistance. Farmers cultivate it through the mixed cropping system along with coriander, pulses, sorghum and castor. It belongs to the species G.arboreum (an old-world cotton). Experimentation on the fabric is currently on, and successful demonstrations reveal that fabric can be woven from this cotton. It can be used to create t-shirts by knitting and dhotis by weaving. This has peaked interest among the people. Earlier, Sahaja Samrudha had conducted the experiments, and currently the project is being strengthened through partnership with ASSEFA.

How has Sura helped the women financially?

Sura women are able to save ?2,500 every month towards their children's expenses. Earlier, they used to depend on their husband's permission to use money at home. Now, it's not the case anymore. They've become more financially independent.

Tell us about Kurinijipadi.

The Kurinjipadi cluster in Cuddalore has over 5,000 looms contributing to about 25 per cent of the state's annual export earnings. The products were exported to and were in great demand in Malaysia, Indonesia, Singapore and Dubai. A walk through Kurinjipadi now makes the shift to powerloom very clear. Most weavers have shifted to powerlooms for better wages and earning prospects.

Cuddalore is a predominantly coastal district, with 22 per cent of the population belonging to the SC community and over 50 per cent population living in rural areas. A disaster-prone region, Cuddalore has been hit by the tsunami in 2004, the Vardha cyclone and the Chennai floods in the past two decades. The project of growing Karungani cotton is to initiate the crop season in Kallupatti in Madurai.

What are the future plans for Sura and ASSEFA?

We want Sura to be a proof point of what is possible for women across communities that ASSEFA works with and beyond. The Sura team itself is on to the path of learning financial methods, computers and the English language to manage different aspects of running an entrepreneurial venture. We want to create an interdependent ecosystem, where teams of women's groups stitch different product lines.

Who are the people heading Sura?

The Sura team is led by Vaanvizhi, Madhu, Senthamizh, Shobana and Chinnamalar who are operating with a spirit of collective leadership and decision-making. My team member Shivaranjani, who works as a community lead with the Cuddalore ASSEFA project, and I handle marketing. We facilitate spaces for collective decision-making and problem-solving.

What is the purpose of Sura? What are the products being made? Where are those available?

Sura exists as a proof point to establish that in disadvantaged communities financially secure families go a long way in supporting the future generation of a community, and also to explore the power in women in contributing to financial sustainability of a family.

Team Sura has created bedcover sets, divan and cushion cover sets, cotton totes, sling bags, pencil pouches, lunch bags, gift bags, denim totes and wedding give-away bags. We are also keen to explore new designs and seek inspiration and orders to expand our repertoire. The prices range from ₹50 to ₹350 and, for bulk orders above 50 pieces there are revised prices. The products are sold mostly online through Facebook/Instagram/WhatsApp.