Our products are 100 per cent environment-friendly

Creative Bee was launched in 1998 by Bina Rao and her husband K Siva Kesava Rao, in Hyderabad and has been responsible for promoting crafts, fabrics and traditional prints in India and abroad. The couple has a long list of admirers who swear by their creations and are loyal followers of their work. Bina and Kesava Rao reveal to Meher Castelino their journey and dreams for Creative Bee.

Do you work with the weavers on a project basis or is it more regular?

BR: Long-term regular basis so that under the projects a large number of weavers and dyers are supported for a stipulated time.

Tell us something about your background.

Bina Rao: I was born and brought up in a Gujarati family. My grandfather was a landlord in village Dhamdachi, Valsad and I grew up in a lush green mango vadi in a big mansion. Playing with the children of farmers and estate workers and eating in their homes, kept me close to rural life. My father was a doctor, horticulturist and philanthropist. He encouraged me in reading literature, listening to Hindustani classical music and painting too. He was also Gandhian and used only khadi. So, as a child I was used to the comforts of handspun-handwoven clothing. I studied at the village primary school and then at the girls' high school at the district headquarters. My aptitude for art and music got me admission in the Faculty of Fine Arts, Maharaja Sayajirao University, Vadodara.

Kesav (Shiv Kesava Rao) came from Hyderabad to do his MA in graphics; we were classmates. I then went to the National Institute of Design in Ahmedabad and did my AEP Textile Design. We got married after a lot of agitation in my family.

What made you and Kesav Rao start Creative Bee?

BR: Those days there were not many opportunities for designers. During the first few years, I practised as a consultant from a small office space and realised that the handloom sector urgently needed re-positioning. Weavers of Andhra Pradesh and elsewhere in India had exquisite skills, but the quality of yarn, dyes, etc were deteriorating rapidly. Kesav was busy establishing himself as an artist; I was restless to set up an R&D handloom unit where I could experiment with new designs. He helped me set up the design and production facility, which is now known as Creative Bee.

It took over a decade to establish the almost vertically integrated production of handwoven and natural dyed production facility, which also includes the Creative Bee Dye farm, which is a result of Kesav's research of many years in reviving and standardising natural dyes. Then, we established market linkages with Indian and international buyers, adding a fashion wing to Creative Bee. The launch of the Bina Rao label took another decade. We believed in sharing knowledge and Creative Bee needed direct revenue to be generated, as our business which was more of a social venture with Fairtrade like policies needed a secondary source of funds. So, Creative Bee's knowledge division was established and eventually Creative Bee became a hub of the highest quality of hand-crafted fashion and textiles. Advisory, training and consultancy projects from the government and other international organisations are taken up under this division.

Telangana has a rich textiles history. What needs to be done to preserve the arts and crafts of yore?

KSKR: Yes, we are one of the states with a textiles legacy of many centuries and a large handloom production. We are trying to contemporise local skills such as ikat and finding new large scale markets for them. In 2016, we were appointed senior consultants to the UN for natural dyes and weaving advisory for East African countries. Creative Bee was made a technical partner for large scale training and entrepreneur skill building programme Disha that is supported by the Ikea Foundation, and implemented by the UNDP and IDF for women weavers from Yadadri, Nalagonda, Warangal and Siddipet in Telangana.

What does it take to create new weaves? Why do we not see creations of new weaves anymore?

BR: It will take more designers to work in the sector, and more R&D facilities.

Why did you pick Hyderabad as the city for your workshop?

BR: We chose Hyderabad as our home and work place. I had specialised in handloom, and Andhra Pradesh offered me a ready platform to work with a large number of weavers. My journey in hand-crafted textiles and fashion began in 1992.

How difficult or easy was it to set up such a complex workshop?

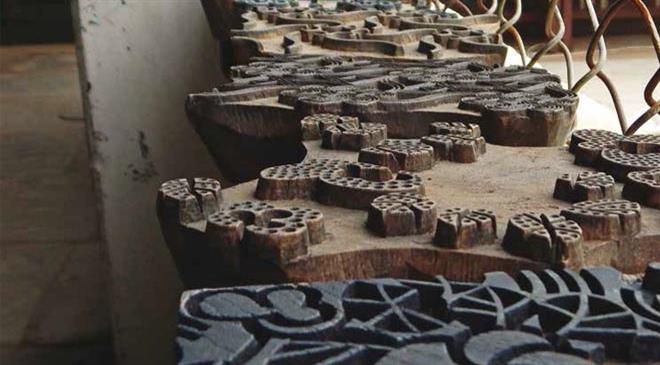

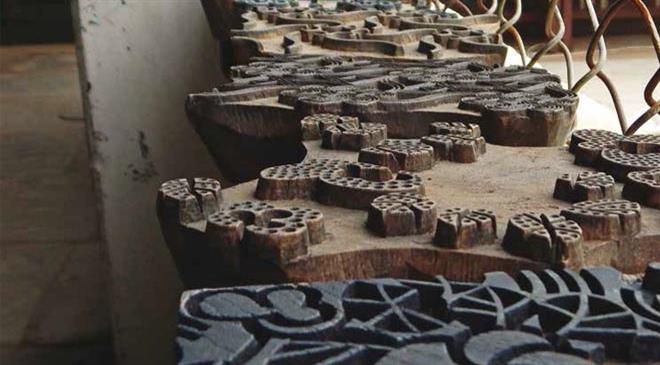

BR: It was extremely difficult, as Hyderabad didn't have blockprinting activities those days. As part of my consulting projects to set up an all-India handloom showroom, I was travelling to various parts of Andhra Pradesh. Machilipatnam was the place where the block print of kalamkari had originated, and I saw that a number of printers didn't have enough work. Few years later, when we were ready with the farm set-up, we invited four families of block printers to come and work with us. Kesav had trained them in the natural dye process that he has evolved through his R&D, and it is over 15 years now that they have been working at the farm. At the farm, we have built a small community, and there are no supervisors or managers. All artisans and their children (who are sent to an English medium school) have a sense of belonging to the farm. On (certain) days, women workers from the nearby village, who have been trained in clamp dyework, come on their own.

Ninety per cent of the deadline in terms of production is met with. Kesav divides his time between the farm and his studio (www.kesav. in). We don't sell the harvest of the farm. Kesav says let the birds and children eat first; then distribute to friends and neighbours. The buildings on the farm required a lot of investment from time to time and though we do not use any heavy equipment, we do need other amenities. The place was built brick by brick and it has the look of natural wilderness. Also, running a design studio was not easy. It blocks huge amounts of capital in samples, prototypes, library, updated equipment, yarn, blocks, dyes, raw materials, etc. For any cottage industry, there are constant challenges in sustaining, and then expanding to sustain it further.

Have you come up with any new organic shades from the ancient systems of developing colours?

BR: All shades of colours existed in the form of natural colourants for clothing as well as food over centuries; we had lost the knowhow. At the Creative Bee farm, we produce almost all natural dye colour shades needed for global fashion.

What is the kind of R&D taken up at your studio? What percentage of your profit goes towards R&D?

KSKR: R&D is a constant activity; 30 per cent of our cost goes into that.

How many prints/weaves/ collections do you create in a year?

K Siva Kesava Rao: Numerous.

Are the designs created according to the customers' needs?

KSKR: We have a White Label for customised products created for customers against their orders. New products are constantly developed by me along with the Creative Bee team for retail and export.

Is the weaving, printing and dyeing done only in Hyderabad?

KSKR: We have trained weavers' groups not only in Telangana but also in Andhra Pradesh, Maharashtra and Chhattisgarh. The Creative Bee Dye farm is 40 km away from Hyderabad at Ghatkesar village. All our natural dyed-printed textiles are produced only at the farm.

What is the production per month of the fabrics when woven and when printed?

KSKR: Approximately 15,000 metres, all products put together.

What are the minimum and maximum quantities that you accept?

KSKR: Fabrics need to be 50 metres minimum for weaves, prints and yes. Saris, dupattas, stoles and garments are in multiples of 12. We also do a home line for large orders, as our looms include 110" wide ones.

Where are the fabrics exported to? Are the fabrics available in India?

BR: About 40 per cent of our production is exported to Japan, the US and the UK. All our products are available at our flagship store in Hyderabad. Creative Bee has shop-in-shops at Kochi and Goa.

What are the various products that are created by the brand?

KSKR: Technique-wise we have ikat, upada, jamdani, plain weaves of chirala and mangalgiri, tussar and silk mix signature weaves of Bina Rao. We have thousands of blocks; some are revival of traditional kalamkari, some are themebased contemporary designs and custom-made designs of Japanese and other clients. We have revived hand-painted kalamkari in its highest quality; historic designs based on palmpore-chintz, and custom-made designs for European buyers are produced as well.

How do you comply with environment protection when it comes to the printing and dyeing?

BR: Our products are 100 per cent environment-friendly. We do not use any harmful ingredients in our natural dyes. We use zero electricity in all our processes, except garments.

Are the garments created by your studio or by freelance designers?

BR: We have an in-house facility for prototypes. The Bina Rao products are designed by me; the Creative Bee label is designed by our panel of designers sometimes as per my brief or design brief from a client.

You have 400 weavers all over India. Do they work exclusively for you?

BR: Not exactly, but at least 50 per cent of the looms are continuously producing for us, and the weavers are paid higher wages than prescribed norms. There is no rejection or deduction made for damage.

What has Creative Bee done to publicise the brand?

KSKR: Not much; it is almost word-of-mouth and our growth is an organic, slow but sustainable growth.

What about your fashion house, The Design Studio?

BR: It is at Banjara Hills, Hyderabad. We have kept our design studio facility open to all designers. A number of Indian as well as foreign designers visit the facility, spend a few days, and develop their collections. The studio has quite a large archive of references and samples of two and half decades of our own work.

What is the set-up with the weavers like?

KSKR: Creative Bee has a policy of training weavers to use azofree and low-impact organic acid dyes, and then modifying their looms to get flawless weaving; making them understand the variations of different reeds, paper designs and colour trends. In 3-6 months they are ready to produce the desired quality and design. Then onwards, we support them with seamless production orders.

Tell us a bit about the Creative Bee Craft Foundation.

BR: We both are artists at heart and temperament. So, crafts other than textiles too got us interested. Kesav has been extensively working on natural dye projects in Southeast Asia. We have a network of like-minded designers and professionals from Japan, Thailand, Malaysia and Indonesia (World Eco Textiles & Fibre Forum) working at a different level in the crafts sector. We saw that in our country, there is a need of training facilities for artisans of a semi-mechanised facility to prepare raw materials for large and unified productions of Indian crafts. Also, our diagnostic study of Indian hand-craft sector revealed the fact that the business of craft shouldn't have too many inter-mediators for artisans to earn a sustainable income. So, we have kept our craft side involvement, non-profit, (Creative Bee Craft Foundation), limiting it only to training and direct linkages of trained artisans to retail chain stores.

What are the different weaves that Creative Bee has?

KSKR: Creative Bee has revived a number of traditional weaving techniques of Andhra Pradesh and Telangana and transformed them into modern designs and trendy colour palettes. We now don't use their traditional names as most of them fall under GI protection and as a designer my strength is in creating new textures by using a variety of hand-spun wild silks, linen and cotton; so, these are like our signature weaves and we dye them in natural dyes and print, hand paint or tie-dye on them. The textures look amazing and almost impossible to replicate by others.

How do your training programmes work?

KSKR: We conduct training programmes (10 days to longterm as well as turnkey) only for resource people such as dyers, weavers and professors. The training programme has to be supported by the government of respective countries or NGOs, UNDP, etc. We also offer one-day exposure visits to the Creative Bee Dye Farm for foreign groups coming from wellknown organisations for textile tours to India.

What has been the response to your brand in the West?

BR: Good. If we had the ambition to expand, we would have expanded multifold with offices in many countries.

What sort of bulk orders can Creative Bee handle?

BR: We can handle up to 2,500 metres (mix of yardage, saris, stoles, etc) per month. In prints and weaves, we can do as much as 10,000 metres, and for handpainting and tie-dye we can do 200 metres. For garments, we can do 500 pieces. Usually, a lead time of 30 days is needed. So, our production cycle is 60-70 days.

How is the Creative Bee brand marketed in India and aboard?

BR: Through retail, e-commerce and high-end fashion boutiques. And also www.creativebee.in.