Want to be next company with unicorn status

Founded in New Delhi in 2009 by two entrepreneurs, Amit Gupta and Nitin Kapoor, Indian Beautiful Art, also known as IBA Craft, is one of the largest online sellers of Indian products globally. In an interview with Paulami Chatterjee, Nitin Kapoor discusses why he built a company for post-consumer textile waste, the initial hardships faced and their now patented JITGM technology.

How scalable is your technology? How many orders can it handle at the most?

I would say it is a robust model wherein the technology can handle as many orders as the infrastructure is there to support the same, and it is scalable as per the orders received from the customer.

On the front end, we leverage our technology to showcase new designs to our customers, and on the backend, we have our inventory protected by not having the garment produced in anticipation.

What was the seed money you began IBA with? How has it grown through the years?

We started in a small 10X10 square feet room with ₹10,000 investment in the company, and today we have over 200 crore of gross merchandise value (GMV) achieved and all this in e-commerce exports business. So that is the amount that we have got into the country from exports.

At this stage, we are at a $5 million run rate. With Just in Time (JIT) in our business process already implemented, we have a virtual inventory worth ₹1,000 crore that can be developed within 48 hours after receiving an order. By this, we are foreseeing a 100 crore revenue run rate within 12-18 months. All the profits have been ploughed back into the business so far (ours is not a venture capital-funded company yet), but we plan to raise funds shortly by which we can have first movers advantage with JIT.

What is your team size now?

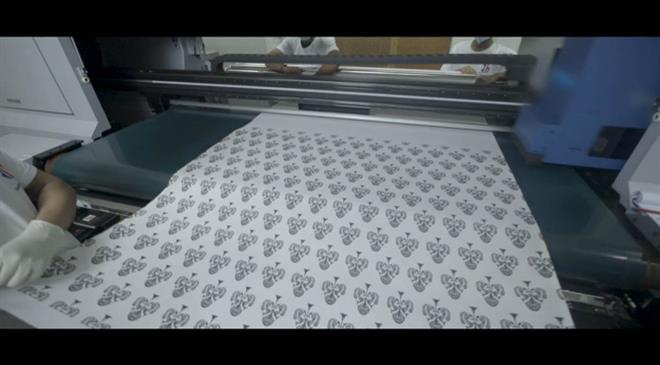

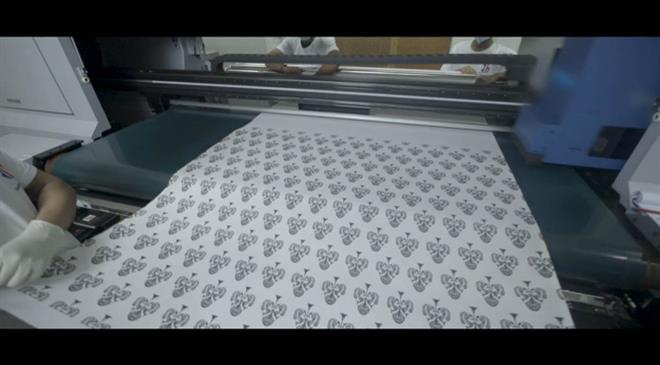

We have 300 people working with us in different departments like graphics, textiles, production, data management and information technology. We have imported high-tech machinery from Japan and Korea that have high standards in garment manufacturing with eco-friendly techniques and processes.

How is the global market responding to this technology? Do you see brands and consumers welcoming your solutions?

Global clothing sales see $1.2 trillion worth transactions annually, and the women's fashion apparel space is expected to grow at 50 per cent year on year from 2025 (currently it is 5-10 per cent).

Customers prefer multiple purchase options, and to take advantage of this huge market, IBA's JIT technology has created a front end where an extensive collection of clothing designs, prints, embroideries, colours with images closer to augmented reality for customers to choose from are offered. Repeat purchases will occur for new fashion designs without maintaining an inventory.

Furthermore, the process is commercially and socially viable as well. Fast fashion nowadays has a lot of unsold inventory that ultimately gets dumped into landfills, and unused resources used to create the garments also get wasted. So we make the garment after the customer places the order.

Competitive advantage:

- Massive offerings of designs and patterns available under one umbrella.

- Huge variety of prints/embroideries/colours available under the same model and design.

- All sizes available all the time.

- No stock-outs

Where do you source your raw materials from?

We source our raw material from South India. Our raw material is white grey fabric, which is used for all garments.

How did the idea of doing something about post-consumer waste arise?

The textile industry today is the second most polluting in the world and has reached an inflection point with competitive and environmental pressures demanding a new approach to manufacturing. It has become necessary that the textile industry must lead the way with more modern technology and innovation for cleaner processes that save energy and water.

With the inclusion of disruptive technology, i.e Just In Time Garments Manufacturing (JITGM), a copyrighted process with the government of India, it is expected that this new technology will reduce the waste of resources especially water. Here, the customer will place an order via augmented reality (AR) images, which will offer customers multiple choices of fabrics/colours/prints/embroideries. The garment would then be manufactured within 48 hours.

What were the key findings of the study that you carried out on the channels of recycling of post-consumer apparel waste in India?

The United Nations is warning the nations that half of the global populations could be facing water shortages by the time we reach 2030, and attempts need to be made to conserve the resources. The hypothesis is that the consumer is not willing to sacrifice personal utility for broader social gains. However, we think that the comprehensive information about environment-friendly products can push suppliers to use cleaner technologies to make products that can be graded as eco labels.

Demand-oriented production, or what we call demand-driven manufacturing (DDM), is a process where production is based on real orders rather than speculation of market demand. This process is also called lean manufacturing or JIT (Just in Time) manufacturing.

Lean manufacturing removes over/mass production of any product created before customer demand arises. Furthermore, it eliminates all kinds of wastes like:

- Inventory waste: all raw materials, work in progress (WIP), and inventory held by the company

- Transportation waste

- Waste of over processing: producing more than customer demand

- Waste of defects: parts or services that do not meet customer requirements

- Waste of resources: wasting electricity, gas, water and other resources.

Which are your major markets worldwide?

IBA has shipped over a million product pieces to over 136 countries, crossing revenues of $5 million. Our major markets are the United States, the United Kingdom, Europe and Australia. The company proudly boasts a steady base of 500,000 customers around the world.

What are the challenges you face in your day to day operations, return products, etc?

Our process is fully automated at all levels to ensure the highest level of efficiency. Still, there are days when we face issues when the colour does not match with the product on screen as we do backward integration where the product is manufactured after it is sold via our AR images. We need to ensure that the final product matches the screen colours. Though this problem is there in 1 per cent of the orders, we still want to reduce this to 0.10 per cent.

What issues of the garment industry can technology solve? What are some of the upcoming technologies in this niche?

Technology today can solve many problems and can create healthy living, better health, education, etc. If implemented and used correctly, it can solve one of the worst problems, i.e mass production, which is one of the seven wastes; it is difficult to ascertain all other issues within the processes.

JITGM will reduce the waste of resources, especially water. Some other technologies like 3D printing, near field communication (NFC), interactive clothing, virtual reality (VR) modelling, non-toxic FR alternative to PVC, ceramic non-wovens, automotive composites, colour changing fabrics, self-healing fabrics are revolutionising the process of manufacturing and the way we dress.

What were the initial challenges you faced while developing and later implementing this technology? How were the challenges tackled?

The challenge was that the vendors, compliance, government officials did not understand e-commerce as a business. So we had to face a lot of problems to complete our transactions as per the law. When we began, start-up was not a buzzword, and leaving an MNC job at that time was still a taboo as compared to today when people and parents are more educated.

Furthermore, when we pivoted our model from inventory led to JIT in 2015, it took us 24 months and $1 million (self-funded) to crack the JIT model in garment manufacturing. After many trials and errors, we could conclude the final product.

We could not create high demand garments due to certain prints or fabrics being out of stock and that resulted in piling of unsold inventory and outdated designs. Another challenge we faced was holding the inventory, i.e, safekeeping and diluting it at throwaway prices.

To convert these problems into opportunities, we launched the JIT system for garment manufacturing. After many changes and improvisations on the technology and manufacturing front, the company decided to call it Textech-Textile Technology. The objective is to produce what is demanded by the market and control the utilisation of natural resources and prevent dumping of waste fabric or garment.

The problem is being solved in two parts now. Instead of getting prints of the photoshoot, images on the clothes are tested using technology. This effectively cuts the cost of photoshoot production and creates a single prototype for various patterns of the same garment. The colours and designs are changed directly saving time, resources and labour.

Secondly, the garment is only manufactured once the customer has placed his order. Right from printing to dispatching the product, the order is managed within 48 hours. The other interesting fact is that there is no pattern master in the company. After the printing is done on the white-grey fabric, it is cut out into the ordered pattern from a machine within 30 seconds with precision.

With JIT in place, we can leverage the garments by making them in-stock always and create new designs daily where we do not have to stock the inventory. This way our business capital is not locked in unsold inventory.

What are your growth expectations from the company for the next two fiscals?

We are already at a 3.5 crore run rate per month after recovering from the COVID-induced situation and now we are expecting cent per cent growth in the next two fiscals.

What improvements would you like to do in your technology going forward?

The next in e-commerce would be videos, and we are working on technology where we would be able to change multiple colours, prints and embroidery from a single video shoot itself, and thus provide real-life experience to our customers. This way they will be able to buy new and fresh products from us.

What are your future plans?

We plan to start O2O (online to offline) model in garments, where the customer would check a sample of the product in the physical store and then buy the colour or print by looking at the model image. By this, there is a great sense of satisfaction for material and size as this has already been tried by the customer. With our vast catalogue of colours and prints, the model wearing the same dress would attract more customers and we would be able to create repeat customers for new designs.

We would change the way people shop for garments in the coming future and would like to be the next company having the unicorn status.