We need alternatives in all stages of the supply chain

TrusTrace is a digital solution provider in traceability, circularity and sustainability. It enables brands and manufacturers to transform their supply chain and product portfolio to align with their sustainability goals. In a chat with Hiral Oza, founder Saravanan Parisutham describes the journey that began as a drive to clean a nearby river to building a solution to make the industry clean.

Which countries are you active in? How many companies are you working with?

We have users across 24 countries across the globe. The brands are predominantly from Europe-Nordics, Germany, France being the key areas, while the manufacturer base is spread across India, China, Italy, Portugal, Taiwan, Korea, Turkey, etc. Currently, we work with 25 brands and about 1,900 suppliers.

How and when did you start TrusTrace? What was the motivation behind it?

I started TrusTrace in 2016 when I saw the river in which I played as a kid and our farm water getting contaminated with effluent discharge from nearby industries. I felt like I needed to solve the problem. Unfortunately, it turned out to be a global rather than a local task. The digital solutions that I built back then became the foundation of the company my friends Hrishi, Shameek, Madhava and I founded together. Given our presence in Coimbatore and the large impact of the textiles industry, it was only natural for us to start building the solution for the fashion industry.

TrusTrace was found as a result of various incidents that took place in the lives of all the founders at around the same time. Personally, for me, the contamination of a local river and underground water table in my hometown, Coimbatore, was the primary reason that urged me to want to do something for the society. The city is also known as the Manchester of South India for the cotton it produces and the number of textile industries it gave birth to. It was heart-breaking to see the amount of waste that was discharged into waterbodies. It was then that I realised the problem needed a global solution, which resulted in the process of ideation and the birth of TrusTrace.

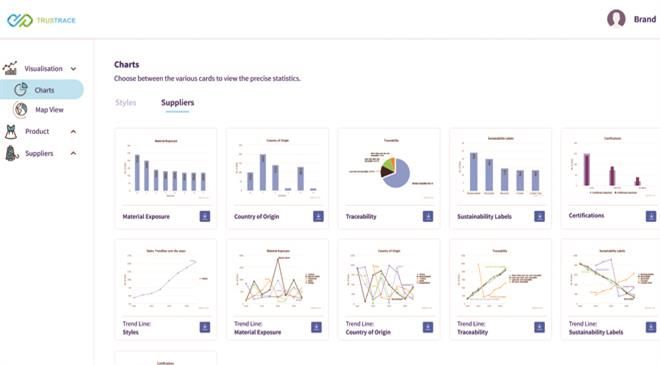

Can you please describe the process once a company plans to on-board? How do you measure, monitor and communicate?

We typically start with a "discovery workshop" where we identify along with the customer:

- their current maturity in terms of traceability,

- what is their business driver for traceability,

- user groups that will use the solution,

- other IT system integrations needed.

At the end of the workshop, we develop a traceability calendar for the customer and what other activities can be combined with this. We also clearly define which systems within the customer or within the customer's partner ecosystem will consume the traceability data. This enables us to help the customer monetise the data from traceability.

We understand that brands, manufacturers would like to test the solution to see how well we address their requirements before making a large-scale implementation. So, we typically start with a 45/60-day pilot, where the user can experience the platform and share with the customer success team any enhancements that are needed.

We start with a pilot where a company has access to all the modules on the platform. We have a dedicated customer support team that provides a complete walkthrough of the platform and help the brands get acclimatised to the platform. After the three-month pilot, the brand gets to decide on what modules fit their needs. If there are additional requirements, we try accommodating it.

What were the initial challenges you faced for developing a solution to measure and monitor activities in the supply chain? The initial challenges were around the funds needed to develop a global solution that could be adopted by suppliers from at least 30 different countries. Developing a solution that is easy to use for all the users across different regions, needed extensive user research. Another key challenge was to bring various stakeholders together and bring a change in the way they interacted with each other-traceability and transparency was a different way of working and it was a significant change.

However, given our belief in the idea and the strong demand from the market, we invested our savings to kickstart the activities. To address the challenge around change management we decided that we cannot provide just a software tool. It was important for us to provide the entire solution- consultation, stakeholder onboarding, use case definition with customers, etc. This has proven to be one key feature of our approach that has been very well appreciated now. The solution itself is a futuristic one and for the brands to believe in the need for such a platform was slightly difficult. They did not see the product as a requirement. It was looked upon as a value addition. Later, with growing awareness among brands and consumers, it has now led a lot of brands take a step closer towards sustainability.

Which stages in supply chain from procuring raw material to recycling waste need the most environment friendly alternatives?

We see that different stages of production and consumption have different impacts on the environment and it would be very difficult and incorrect to single out just one action/ stage of production as the one that needs most improvement. Given the current state of our planet, we need alternatives in all stages of the supply chain, and we need them quick. From a simplified perspective though, the way we can create a maximum positive impact is if we can reduce consumption by switching to long-lasting sustainable products. The next step would be to decrease the waste in our supply chains, our closets and decrease our left-over stocks. If we can extend the life of garments, regenerate fibre from old garments and move towards a real-circular model right from design to production to consumption, we can address the environmental impact to a great extent.

What are the main challenges that manufacturers and companies encounter?

The basic challenge is the size of the supply chain. Unlike the other industries, there are lot of raw materials used and lot of processes that are carried out before a garment is delivered in the hands of the customer. Tracking, monitoring and implementing any change to the supply chain is slightly difficult. Sometimes suppliers will have to provide information and since they belong to developing nations, it is slightly difficult for them to provide data on software platforms. They also think of it as a time-consuming process and do not see a face value in the work they do.

Who are the key investors in TrusTrace?

The four founders are the major shareholders. TrusTrace was a bootstrapped company till August 2019. Recently, we onboarded Backing Minds as our investor, given their strong network and knowledge of the European fashion industry. Initially, the organisation was run with the help of grants we won from Vinnova. At present, Backing Minds are the only and key investors in TrusTrace.

What parameters are set to calculate transparency, ethical trading, sustainability, and circularity?

We collect information about the "product" as well as the "facility" in which it was produced. Depending upon the need of the user, the information collected varies. However, the predominant information collected is the summary of various raw materials, source or supplier of these various raw materials used in the production of a garment or fabric. We also collect how the production happens to understand the process behind the product as well. Whenever there is a certified product claim, we collect the relevant certificates from the value chain-like GOTS transaction certificate for organic, GRS for recycled products, RWS for wool products etc.

At a facility level, we record:

- Audits, the score of the audits,

- non-conformities and help implement and track a continuous action plan

- Facility certificates, their expiry dates and help brands and suppliers manage that effectively

- Social and environmental data points like gender diversity, compliance to living wage / fair wage, EHS implementation, water usage, energy usage, emissions etc.

We track special / innovative projects implemented at factories and highlight those to the brands such as innovative dyeing techniques, social programmes, carbon positive initiatives, etc.

What are the biggest issues in making the textile supply chain transparent?

Although many brands are very keen on making the supply chain transparent, not all the suppliers see a monetary value in sharing the supply chain information with the brands. Supply chain traceability is seen as an action that adds to the overhead without any immediate returns to the suppliers. We believe this is because the current ways to managing and sharing data with brands can be difficult for suppliers and that is where we think automation and digital solutions can play a huge role. With increasing demand for the brands with traceability in terms of government regulation in Europe, it's a matter of time the manufacturers are mandated to share the information.

What new solutions do you plan to come up with in future?

Our vision is to provide a single-stop solution for brands, suppliers and other ecosystem players in the area of sustainability, circularity, traceability. While our solution has been stable and delivering consistent results in the area of traceability, we look to improve our offerings in other areas. We have collaborated with key partners like Position Green, Circular Fashion to provide Scope 1, 2 & 3 emissions tracking and circular design guidelines. We are also working with recyclers, sorters, etc to increase the efficiency of take back programmes and other circular models.