In next 5 years plan to touch 25 mn/year revenue

Founded with an investment of 12 million USD in 2005, Viet Hong Textile is a major denim fabric manufacturer in Vietnam today. In an interview with Fibre2Fashion, Quinn Hang, Vice Director of Viet Hong, discusses the strengths of the Vietnamese denim market, the government policies which are leveraging the textile industry at large and how Viet Hong managed to stay afloat even during the pandemic.

How big is the market for denim fabric in Vietnam? What percentage is exported annually?

In 2020, the total export value of Vietnam amounted to Free On Board (FOB) US $29,810B (garment and textile), in which around US $1.875 billion was generated from locally manufactured denim fabric.

What are your marketing and communication strategies? What steps are you taking to build your brand?

Viet Hong Textile is actively strengthening its marketing campaigns via social media platforms such Facebook/YouTube/LinkedIn and e-showrooms. We are part of DE Brands, Four Source, and we have our owned billboards around Vietnam. Shortly we will be distributing our product package booths to our solid vendors and new buyers.

Our marketing and communication strategy is mostly word of mouth as we maintain consistent quality. The garment factories we work with refer their customers to us and we support them locally. Our inhouse sample laundry and designers assist our customers in terms of washing recipe at times when they are not able to meet the styles, we use for washing inhouse.

Before the pandemic, we had visited exhibitions in Hong Kong, Shanghai, New York (Blueprint), Vietnam (Denim and Jeans), Cotton Inc, US and paid annual visits to customers' offices abroad.

How have the coronavirus pandemic impacted your business? Kindly share at length.

The current pandemic not only affected our business, but it has also affected everyone around. Many people lost their livelihoods, people got sick and lost their loved ones, many businesses closed in many countries. Viet Hong stayed on the ground and we survived. Despite the pandemic, 2020 was a good year for us.

What are the strengths of Vietnam as a denim producing country compared to rest of the world?

The strength of Vietnam as a denim producing country in comparison to its neighbouring countries, is that we have 10 bilateral and multi-lateral trade agreements with groups and organisations such as ASEAN Free Trade Area, FTAs with Japan, South Korea, Chile, Russia and EURASIA Economic Union, and countries which are expected to execute CPTPP and EVFTA such as Canada in 2022.

The investment amount in Vietnam is considered lower than its neighbouring countries as Vietnam has all the needed infrastructure; mills can just erect their machinery on ready facilities here to start production. The other strengths of Vietnam are as below:

- Large domestic consumption

- Vietnam has a population of almost 100 million. Workers are skilled and young.

- Vietnam has vast number of foreign workers hired from different countries to support the industry and transfer necessary technology.

- Companies of Vietnam are still investing, and more foreign investments are pouring in.

- Buyer influx is coming out from China to Vietnam.

- The industry is still looking for a life span up to 10-15 more years.

What is the annual yardage of denim manufactured in Vietnam and what is the percentage pie that your company would like to claim?

The estimated amount of denim being manufactured by local mills in Vietnam amounts to about 75 million metres a year in which Viet Hong produces 15 million metres.

What was the company's turnover last fiscal? What are your sales projections for the next 5 years?

Total Company Sales Volume (for last 5 years):

Year Sales volume (US$)

2016 12.9 million

2017 13.9 million

2018 14.9 million

2019 18.8 million

2020 14.5 million

In the next 5 years, we are planning to touch 25 million/year.

Any plans to expand your current capacities or introduce new products in the near future? Do you plan to set up a physical store anytime soon?

Viet Hong Textile is open to expansion not only in terms of our facilities but also for our market reach. Due to the current economic situation brought forth by Covid, investment is on hold. But we continue to reach out to our current and prospective customers to win more market share. Physical store is not on our plan at present, but we are exploring the idea of having our own brand soon.

How does the government support the textile industry at large? What are the top 3-5 unique policies that are helping this sector?

The Vietnam government has taken necessary steps to help the textile industry in assessing the supply chain of Foreign Direct Investment (FDI) enterprises.

The government has issued 68/2017/QD-TTG to promote, support and attract domestic and foreign investment which have the following policies:

1.Land rental fee incentives (the supporting industry zone will receive an exemption for 11 years)

2.Tax incentives (Corporate Income Tax (CIT) reduction, import duties, VAT)

3.Financing (R&D incentives, investment credit, environment protection schemes)

Which colours, trims, fabric etc will dominate SS2020? What future trends do you foresee?

In SS2021/2022 - dark blue/mid colour denim washes will be the dominant colours; vintage washes will still be around. Moreover, the classic tied dye, dark bleach washes are anticipated to make a comeback.

Where do you source the denim fabrics and accessories from? Are you working with third party suppliers?

We source our yarns from Vietnam and some other nearby countries through our procurement department. Since we have a strong team, third party sourcing is not needed.

What is your annual production capacity?

Our annual production capacity is around 15 million fabric metres per year.

How was Viet Hong Textile formed? How many people and how much funding did you begin with?

Viet Hong Textile JVC was established in 2005 and owned by Viet Huong Group, a family-owned business group with more than 30 years of entrepreneurial experience. With passionate and open-minded management along with our young and energetic staff, we were able to evolve out of a traditional local mill. Nowadays, Viet Hong is known as a reliable denim textile manufacturer not only in Vietnam but also in the international market.

Initially, Viet Hong Textile started with an investment of 12 million USD and manpower of about 350 people in 2005-2006. Gradually we increased our investment by purchasing 60 more weaving looms (Toyota and Picanol) and sanforising machine (Montforts).

How does your supply chain network work? What regions of the world are part of your supply chain?

Our supply chains are mainly focused on Asia, China and some parts of America. These countries supply raw materials like chemicals and some dye stuffs.

What is your R&D team like? How much do you spend on R&D on a yearly basis? What percentage of your profits is ploughed back into R&D?

R&D is the backbone of our company. The R&D team creates ideas based on inputs provided by our customers or inspirations from current trends and translates them into fabrics. We allocate 10 per cent of our revenue for R&D.

Where do the team source information on trends and consumer insights from?

- Customers

- Competitors

- Research

- Internet

- Yarn partners

- Kingpins

- Denim jeans

- Brand

- WGSN

- Four Source

- virtual tradeshows and conferences

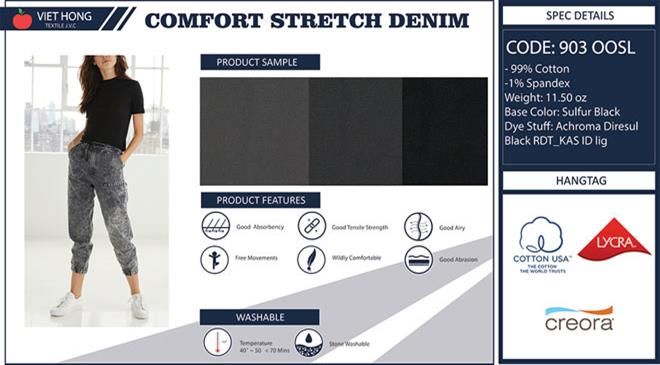

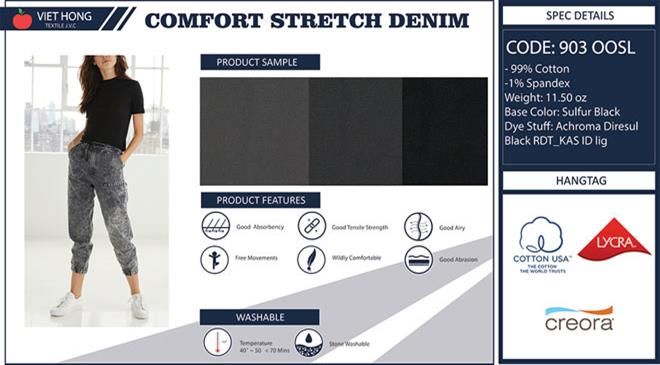

How many types of fabric varieties do you offer?

Our fabrics are categorised as below:

a. Denim fabrics from 5 to14 oz rigid and stretch qualities.

b. Cotton and cotton blended with:

- Polyester

- Viscose/Rayon

- Tencel

- Modal

- T-400

- Spandex/Lycra

- Dual FX T-400 + Lycra

- Coolmax

- S-café

c. Green/sustainable products like Repreve, USA/BCI Cotton, Organic Cotton and Ecovero.

What is the average turn-around time from fabric sourcing to shipment of the same to your clients?

Normal production lead time is 40 to 50 days. Within Vietnam, we can deliver the same day itself after production; overseas it is 10 to 15+ days including custom clearance.

What latest technologies and innovations is your team currently working on?

Our mill is currently set-up with Montforts sanforising machine which saves 40 per cent of water and energy compared to a traditional sanforising machine. We are planning to increase our number of dips to 18 to be able to offer deeper indigo colours.

World over the impact of chemical in denim bleaching has become a serious health concern. Is Viet Hong doing something about it?

Denim bleaching is being done in garment form not in fabric form, therefore the impact is less in denim mills. However, to ensure safety at the workplace, we have conducted a number of training courses for our workers and at the same time we got our factory certified under Oeko-Tex Standard 100.

Which brands and retailers are you currently associated with?

US Market (Express, Urban outfitters, Abercrombie & Fitch, Enjean, Hyper Denim, KDNK, Berksha, Dynamite, Rock Revival)

Japan Market (Edwin, Wego, Torachi)

Korea (Eland - Spao, FRJ, Zamboange)

Others.

From which geographies is the demand for your fabrics most from?

What green initiatives are you undertaking at the production level? What energy savings it is leading to?

Our mill is supported by our own water treatment facility in which 40 per cent of recycled water is used in the manufacturing processes and about 15 to 20 per cent in cleaning processes or watering of the plants.

We also use solar energy to support our electrical needs. Our Montforts sanforising machine saves 25 per cent electricity and 40 per cent on water consumption. For our dyeing process -- we use Archroma liquid indigo.

According to you, which major denim brands make responsible and low impact denim products?

Aeo, GAP, Levis, Target, J-crew, Warp & Weft. (PC)

What is the competition like for you from within Vietnam?

Competition is present in any industry; it makes the business more progressive and challenging. We are not threatened by our competitors as we provide customers with consistent good quality, services on a timely manner and competitive pricing. We always make it a point to go an extra mile, so no pressure is felt from our competitors.