A new, simple double-thread-chain-stitch technology

Uzbekistan-based Zarif Sewing Machine Co. Ltd. was founded by Zarif Sharifovich Tadjibaev in 1994 when Tadjibaev invented a new double thread chain stitch technology that allowed the development of a double thread chain stitch sewing machine with a very simple mechanical design. In an interview with Paulami Chatterjee, Tadjibaev speaks at length about the new Zarif double thread chain stitch technology of 2020—an improvised version of his previous stitch technologies.

How did you come up with the new Zarif double thread chain stitch technology? What was the time invested behind this research?

Probably many people are very interested to know about how I came up with the idea of forming a double thread chain stitch using a rotary looper. Generally, thread stitches are divided into two large groups: lockstitches and chain stitches, and they in turn are divided into many types of lockstitches and chain stitches. Accordingly, sewing machines, depending on the type of stitch, are divided into lockstitch and chain stitch ones.

Currently, all modern sewing machines use technologies for forming various types of stitches, which are based on the principle of forming the lockstitch and chain stitch, which were invented in the 19th century. These existing technologies have quite a lot of disadvantages related to the stitch structure as well as technology, and therefore, any improvement could not solve these problems.

Disadvantages of the existing technologies include complex mechanical design of sewing machines, stitch skipping, thread breakage, needle breakage, the need to adjust the threads’ tension when changing the thickness and stiffness of the sewn materials.

It is possible to develop and produce a sewing machine that does not have these issues and other disadvantages only by inventing a new technology for forming a thread stitch. However, that task is difficult, which is confirmed by the fact that modern sewing machines still use technologies for forming thread stitches invented in the 19th century.

Despite this, I still managed to invent in 1994, a Zarif technology for forming a double thread chain stitch using a rotary looper, for which US Patent No 6095069 was issued in 2000. For the first time in the world, Zarif double thread chain stitch technology from 1994 allowed the development of a double thread chain stitch sewing machine with a very simple mechanical design.

The simplicity of the mechanical design of any machine, including a sewing machine, reduces the cost of manufacturing and positively affects its reliability. In addition, I was interested to know how in practice my technology works beginning 1994. Can I get quality stitches when sewing at speeds of 5000 rpm? Would it be possible to sew without skipping stitches, without thread breakage and without breaking the needle and also possible to sew various materials without adjustment of normal tension of threads, and to what thickness of materials we can sew?

I got answers to these questions only after making a prototype of the machine. And in 1997, I started implementing my project.

As there is not a single company engaged in the production of sewing machines in Uzbekistan, it is almost impossible to manufacture a sewing machine from start to finish. In addition, it requires a lot of time and a lot of expenses.

In this regard, I decided to make a prototype sewing machine by reconstructing the designs of existing lockstitch sewing machines to significantly reduce the machine's production time and reduce the financial cost of manufacturing. I made a prototype of a double thread chain stitch sewing machine with a flat platform and bottom feed of material, i.e a type of sewing machine that is very widely used in garment factories for making clothes.

In Uzbekistan, sewing factories then very widely used lockstitch sewing machines with a flat platform and bottom feed of material of class 97-A for sewing light materials with a needle bar stroke of 29 mm and class 1022 for sewing medium materials with a needle bar stroke of 32 mm of Belarusian company Orsha.

I chose a class 1022 lockstitch sewing machine to make my prototype as I wanted it to be able to sew thick materials.

After much research, I was able to find a technical solution for placing my Zarif sewing technology into the mechanical design of a class 1022 lockstitch sewing machine. And in 1997, I manufactured the world's first prototype Zarif double thread chain stitch sewing machine.

After that, I began to practically study my technology by conducting various experiments using a prototype. My experiments on a prototype allowed me to discover some shortcomings of my technology in the process of sewing various materials at speeds up to 5000 rpm.

Starting 1997, I began conducting research to invent the most advanced technology for forming a double thread chain stitch by improving my 1994 technology.

As a result of my experiments from 1997 to 2020, I managed to find quite a lot of knowhow that allowed me to improve my technology thrice—in 2016, 2019 and 2020. After each improvement, I shot a video film to practically demonstrate them and they are all available for viewing on my YouTube channel. My newest technology which was worked upon last year, completes the improvements on the technology from 1994.

Now you need to tighten the loop of the top thread, which is located in the previous stitch, and how can this be done?

It is impossible to tighten the loop of the top thread with a thread take-up, as the loop of the top thread is in the previous stitch and the needle with the top thread is immersed in the material. Only with the help of a needle can you pre-tighten the loop of the top thread, which is in the previous stitch, as after dropping the loop of the top thread from the body of the looper, the needle will continue to move down to the most extreme position, consuming the top thread.

The consumption of the top thread by the needle begins from the moment of immersion in the material of the needle eye and ends in the lowest position of the needle. If you measure the distance between the needle ears when the needle eye is immersed in the material and when the needle is in the lowest position and multiply this distance by two, you get the length of the top thread consumed by the needle.

Thread take-up lever top thread takes such a length of top thread to the needle, which is enough, until reset loop of the top thread from the looper, and then the needle is continuing to move down, beginning to consume the top thread through the reduction of the size of the loop of the top thread in the previous stitch.

When performing this process, the top thread moves over the surface of the needle and the top thread experiences pressure from the material, which creates resistance to the movement of the top thread over the surface of the needle.

To reduce this resistance, a second long groove is made on the needle. It is known that the longitudinal bending strength of such a special needle with two long grooves is lower than that of a standard needle with one long groove.

As the size of the top thread loop is reduced by the needle, a bottom thread loop begins to form on the needle body from the bottom thread. When the needle is raised from the lowest position, a loop-overlap is formed from the top thread, into which the point of the looper enters.

The final tightening of the loop of the top thread is carried out during the feed of the material to the length of the stitch with the help of a looper, on the body of which the next loop of the top thread is located.

With this method of tightening the loop of the top thread, i.e. first pre-tightening the loop of the top thread with a needle, then the final tightening of the loop of the top thread with a looper while feeding the material to the length of the stitch, it is not possible to tighten the loop of the top thread much. Therefore, such a stitch cannot tightly join the materials.

As I mentioned above, with the help of existing technologies for forming a double thread chain stitch, where the looper carries the bottom thread, it is impossible to get a high-quality seam when joining textile and knitted materials with hard materials such as leather and plastic.

This is because increase in the rigidity of the sewn material dramatically increases the material's resistance to movement of the top thread, which cannot be reduced. The result is the needle cannot do a preliminary tightening of the loop of the top thread as is; it begins to consume the top thread from a large spool through the tension device where resistance is lower.

Therefore, the most basic disadvantage of the technologies of forming a double thread chain stitch, where the looper carries the bottom thread, is the participation of the needle in the preliminary tightening of the loop of the top thread located in the previous stitch.

Of course, there is an advantage of the double thread chain stitch type 401, as there is lack of frequent changing of the bottom thread, before forming a lockstitch type 301.

What are the factors which contribute to the advantages of the new technology? What are the benefits that consumers get out of the new technology?

The 2020 technology allows you to significantly expand the scope of the double thread chain stitch for the first time in the world due to wide replacement of the lockstitch in production of various sewing products.

All advantages are achieved through the use of a rotary looper, a needle with one long groove. As the needle does not take part in tightening the loop of the top thread located in the previous stitch, two rotary double-disc cam thread take-ups for feeding and tightening threads, as well as through the use of quite a lot of knowhow.

It is known that the rotary looper, consisting of one part, is the only working unit in the sewing technique that is able to circle the loops of threads around its body by turning them 180 degrees with its tail.

The rotary looper was invented by American inventor James Edward Allen Gibbs in 1857 to form a single-thread chain stitch type 101, where the looper makes one revolution per revolution of the main shaft of the sewing machine. In 1994, I filed a patent application for an invention where I used a rotary looper for the first time in my Zarif double thread chain stitch technology. Before that, it was only used in single thread chain stitch sewing machines and button machines.

As the rotary looper unfolds the loops of threads around its body, by rotating those 180 degrees, I was able to get a new type of 401 double thread chain stitch, where the loop of the top thread and the loop of the bottom thread are rotated 180 degrees.

Therefore, the underside of the new type 401 double thread chain stitch is very similar not with a chain, as is the case with the usual type 401 double thread chain stitch, but to a thick thread laid along the seam. In my new Zarif double thread chain stitch technology, the needle never collides with the body of the looper when moving down, and the probability of the needle colliding with the wall of the needle plate slot is almost zero if the correct needle number is selected corresponding to the thickness and stiffness of the material being sewn.

In addition, my technology offers the following:

- High stability of stitch formation is provided without the use of needle guards.

- High quality tightening of the stitch threads, regardless of the thickness and stiffness of the sewn materials, without changing the normal tension of the threads.

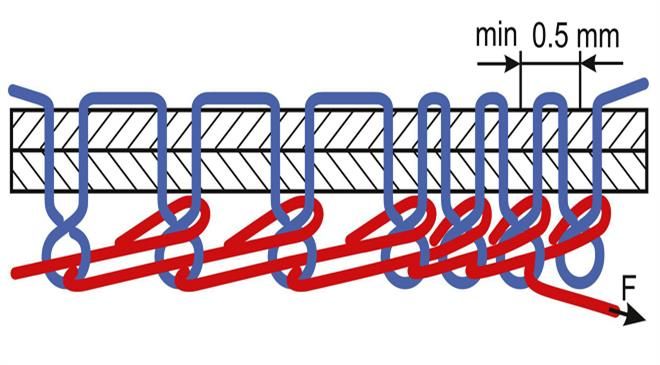

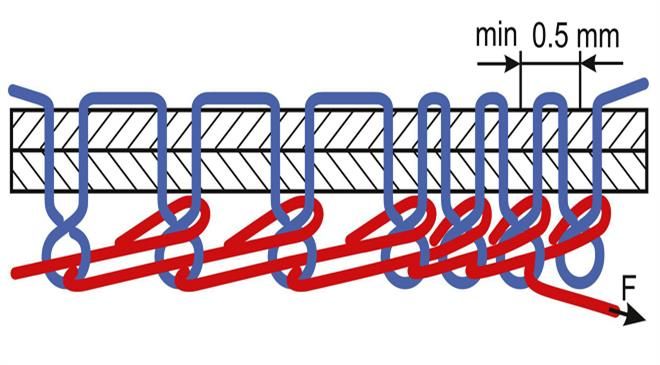

- The maximum allowable gap between the looper point and the needle is increased to 0.5 mm, which eliminates the adjustment of the looper relative to the needle when to switch from needle 130/21 to needle No. 60/8.

- Improved quality of tightening threads for a stitch length of 0.5 mm.

- The thickness of the materials to be sewn is increased to 9 mm with a needle bar stroke length of 32mm.

- The lifting height of the needle from the lowest position to form the loop-overlap from the top thread is the same for sewing all materials up to 9 mm thick, which allows sewing different materials without adjusting the needle bar.

- Provides sewing without skipping a stitch or breaking threads.

- A strong tightening of the loop of the top thread of the stitch is provided, which allows you to tightly join materials and qualitatively join textile and knitted materials with leather and plastic materials, using a double thread chain stitch.

- Allows you to reduce the degree of tightening of the loop of the top thread of the stitch, without changing the normal tension of the threads, so that on light and ultra-light materials you get a smooth seam and on elastic materials you get an elastic seam.

- In a strong tightening, the loop of the top thread of the stitch along with a dense join of materials, the upper side stitch is immersed in the material and the thickness of the bottom side of stitch is reduced, leading to increased durability stitch to wear.

The consumers receive the following benefits:

- A single model of sewing machine with a small needle bar stroke of 32 mm for sewing all materials up to 9 mm thick.

- Increased productivity due to the lack of frequent changer of the lower thread, thread breakage, needle breakage and deformation of the needle tip.

- Increases the quality of the seam due to the increase in the strength and elasticity of the stitch and due to the lack of stitch skipping.

- Allows you to easily sew various materials up to 9 mm thick without adjusting the needle bar and without adjusting the normal tension of threads.

- Allows you too easily to switch from needle No. 130/21 to needle No. 60/8 without adjusting the looper relative to the needle.

- Allows you to securely tacking the end of the chain seam by condensation of stitches, reducing the stitch length to 0.5 mm and using a thread chain on the edge of the material.

- Allows you to tightly join any type of material and a combination of different materials with the new type 401 double thread chain stitch.

- Allows you to get a smooth seam when sewing light and ultra-light materials and an elastic seam when sewing elastic materials.

- Allows to sew very long time without cleaning mud from under the needle plate, due to the fact that the looper consists of a one part and has no hole, no groove and the looper, rotating two times faster than the main shaft, the rotation creates a strong air stream which discards all mud generated from the materials and threads away from the stitch forming zone.

How was your life journey like before you founded Zarif? Where does the company stand today in terms of revenue and sewing machine technology?

After graduating from the Tashkent Institute of Textile and Light Industry, I worked as an engineer at the Central Asian Commissioning Department of Textile Machines from 1984 to 1987, and then in the Tashkent factory for the production of textile machines. In 1987, I moved to the Tashkent Institute of Textile and Light Industry. Initially, I worked there as the head of the laboratory of the department of machine parts, and then as a teacher from 1992 to 1994, I taught in graduate school, and in 2001 I presented my PhD thesis on my 1994 technology. In 2012, I retired from the Tashkent Institute of Textile and Light Industry and founded my company Zarif Sewing Machine Co, Ltd at my own expense.

My company is small and is a technology company and is mainly engaged in improving my technology from 1994 and commercialising it to the industry. My company also sells information technology (IT) products, equipment and accessories for the light industry of Uzbekistan. My company’s profits are small, and therefore, I am unable to independently introduce my technology into the industry. Therefore, I am looking for companies among manufacturers of industrial sewing machines and automated sewing systems that are interested in becoming my partner on mutually beneficial terms to commercialise my technology developed last year.

Who are the probable customers for your new technology? What are the advantages?

With the help of my prototype with a flat platform and with bottom material feed, it is possible to move the material in only one direction along the needle plate slot. Once production starts, the new machines can be widely used in the production of clothing, home textiles, shoes, sneakers, upholstered furniture, car seats, car covers, airbags, soft toys, sleeping bags, tents, bags, backpacks, etc.

My technology allows you to tightly join any materials with a double thread chain stitch and qualitatively join multi-layer materials, where there are combinations of different materials in terms of stiffness, such as textile-leather, textile-plastic, knitwear-leather or knitwear-plastic.

In addition, this technology is the most versatile in the world, as it can qualitatively join any materials up to 9 mm thick with a small needle bar stroke of 32 mm without changing the normal tension of the threads, which is impossible to achieve with existing stitch forming technologies.

At the same time, the technology has the know-how with which you can adjust the degree of tightening of the top thread loop in the stitch, without changing the normal tension of the threads.

If you strongly tighten the loop of the top thread in the stitch, you get a normal stitch, which is used for tight join of materials, and if you slightly tighten the loop of the top thread in the stitch, you can get an elastic stitch, which is used to get a smooth seam on light and ultra-light materials and to get an elastic seam on elastic materials.

In addition, the technology guarantees sewing without breaking threads and needles and without deforming the needle tip, which allows these to operate without an emergency stop.

It also guarantees sewing without stitch skipping and securely tack the end of the chain seam by condensation stitches, reducing the last few stitches to 0.5mm, which is very important for all chain stitch forming technologies, as all chain seams unravel very easily from the skipped stitch towards the beginning and from the end of the seam.

As single-line thread seams are widely used in the production of various sewing products than other types, our future customers can be small and large companies and sole proprietors engaged in producing sewing products.

Tell us about the automatic threads trimmer technology you have invented for your new sewing machine. Have you got it patented?

In 2016, I invented the automatic thread trimmer technology for my use and in 2020, I managed to perfect it. As I haven't filed a patent application for that, I cannot go into its details. I can only say that the trimming of threads is done under the needle plate and after trimming the threads, the end of the bottom thread will be clamped between the knife and the plate spring, to avoid filling the bottom thread.

When are you going to apply for the patent?

I plan to file one patent application for these two new inventions this year, as these are related. I also plan to patent these in multiple countries, namely where there are manufacturers of sewing equipment and where there is a great demand for sewing equipment.

What are the problems associated with automated sewing in general?

The automation of production of many products, including sewing products, is currently taking place at a very high rate. Currently, there are fully automated lines for the production of simple sewing products, such as medical masks, home textile products, mats and T-shirts. However, there are no fully automated lines for the production of complex sewing products due to the presence of many complex technological sewing operations, which are tough to fully automate.

But at the same time, the number of garment factories using automated sewing systems is increasing. In such units, productivity increases and quality improves. The problem of finding highly qualified sewing operators is also solved as it is possible to quickly teach anyone with secondary education to work on automated systems and machines.

No doubt the number of such garment factories will grow. At present, many companies that earlier produced industrial sewing machines have also started manufacturing automated ones.

The main requirements for performing sewing in automatic mode are the continuity of technological sewing operations without an emergency stop due to thread breakage, stitch skipping, needle breakage and needle tip deformation.

What are the problems associated with lockstitch type 301 and double thread chain stitch type 401, which your new technology is going to address?

At present, for joining materials with a single-line thread seam, a lockstitch of type 301 and a double thread chain stitch of type 401 are primarily used. The principle of forming a lockstitch of type 301 is based on passing one branch of the bottom thread through the loop of the top thread and ensuring that the threads are intertwined in the middle of the sewn material.

This type of stitch formation can only be carried out by means of hooks (shuttles) that perform rotational or oscillatory or reciprocating movements, having a point to catch the loop of the top thread formed by the needle and inside which there must be a bobbin on which the bottom thread is wound, which is fed under a certain tension.

A double thread chain stitch of type 401 is based on the passing loop of thread through another loop of thread, that is, the loop of the bottom thread is passed through the loop of the top thread, and then the loop of the top thread is passed through the loop of the bottom thread, and ensuring that the threads are intertwined on the underside of the sewn material.

Invented in the 19th century, the double thread chain stitch type 401 is performed by means of loopers that have a point to catch the loop of the top thread formed by the needle and the eye near the point, through which the bottom thread is passing, which makes complex spatial movement or oscillatory movement along the seam line, working together with spreader thread or oscillatory movement in a horizontal plane.

Lockstitch of type 301

Advantages:

- A relatively small consumption of threads per stitch

- The upper and lower sides of the stitch have the same form, similar to a dotted line

- Stitch on the surface of the material does not create thickening, which makes it more resistant to wear

- The seam is of the lockstitch and does not unravel

Disadvantages:

- The need for accurate adjustment of the yarn tension, so that they are intertwined in the middle of the sewn material.

- Stitching is not suitable for joining elastic materials as it has little stretch

- The strength of the lockstitch is lower than the strength of the double thread chain stitch in the transverse direction.

Double thread chain stitch of type 401

Advantages

- The stitch is more elastic than the lockstitch.

- The bottom thread does not pass through the material

- The stitch in the transverse direction has more strength than the lockstitch as two branches of the bottom thread pass through the loop of the top thread.

Disadvantages

- Relatively high consumption of threads per stitch than the lockstitch.

- The stitch on the bottom surface of the material creates thickening, as threads intertwine on the lower surface of the material, which reduces the resistance of the lower side stitch to wear.

- The seam from the stitch is easily unravelled from the end of the seam and from the place of skipping the stitch towards the beginning of the seam.

Therefore, the technology of forming a double thread chain stitch should provide a reliable tacking of the end of the seam and sew without skipping the stitch.

In any technology of forming a thread stitch, the following processes should occur:

- Holding the top thread through the material with a needle and forming a loop-overlap from the top thread when lifting the needle from the lowest position.

- Interweaving the threads of stitch.

- Feed the material to the length of the stitch.

- Tightening the threads of the stitch.

It should be noted that all technologies of forming a lockstitch of type 301, regardless of the design and type of movement of the hook (shuttle), have the same disadvantages, which are quite a lot.

- Therefore, I will list the disadvantages of forming a lockstitch of type 301 that were corrected in my new technology from last year.

- The first drawback is the need for frequent changing of the bobbin with the bottom thread located inside the hook (shuttle) due to the small size of the bobbin.

- The second drawback is that all types of hooks are complex in design, consist of many parts and are relatively expensive.

- The third is the presence of rubbing surfaces in all types of hooks. Due to this, the hooks must be lubricated. The service life of the hooks is reduced and it is necessary to clean the hooks from dirt, and when a piece of thread enters the rubbing surfaces, a sudden braking of the sewing machine can occur.

- The fourth drawback is the need to adjust the threads’ tension while sewing different materials, even when the top and bottom threads are intertwined in the middle of the sewn material. This is because if the threads have a large tension, the seam may pucker, or break easily when stretched, and if the threads have a weak tension, the seam will gap when pressed open, exposing the threads between the materials. Therefore, using the technology of forming a lockstitch, it is impossible to achieve high-quality sewing of various materials without adjusting the normal tension of the threads.

- The fifth drawback is that with increasing sewing speed, the loss of mechanical strength of the top thread increases during the sewing process. This is because the hooks consume a large length of top thread, and the consumption of top thread per stitch is relatively small, resulting in the top thread passing through the eye of the needle and the material many times before it finally gets taken up in the material.

- The sixth disadvantage is the uneven tightening of the top thread with the help of a thread take-up lever. This is because when forming a lockstitch, the hook consumes a large length of the top thread loop, so the thread take-up lever is forced to quickly reduce and tighten the top thread loop before the needle makes the next puncture of the material. Therefore, it is technically impossible to make a uniform and smooth reduction, tightening the loop of the top thread.

- The seventh is that the maximum allowable gap between the point of the hook and the body of the needle is 0.1 mm. Because of this, when changing from needle No 130/21 to needle No 60/8, it is necessary to adjust the hook relative to the needle.

- The eighth drawback is to increase the reliability of the grip of the hook point loop-overlap of the top thread, it is necessary to adjust the height of the needle rise from the lowest position depending on the thickness, stiffness and elasticity of the materials to be sewn, and also to use the needle guards.

- The ninth is the inability to sew various materials with a thickness of up to 9 mm with a small needle bar stroke of 32 mm, as for sewing heavy materials with a thickness of up to 9 mm, it is necessary to increase the needle bar stroke.

- The tenth is the inability to perform with cent per cent guarantee of the process of entering the point of hook into the loop-overlap of the top thread, which forms the needle, when lifting from the lowest position.

- The eleventh is that in lockstitch, there are factors that can lead to the threads breaking, especially the top thread. Therefore, lockstitch does not guarantee sewing without breaking the threads.

- The twelfth is the needle, when moving down, passes a short distance from the wall of the needle plate opening and from the hook bodies and, therefore, the deflection of the needle can lead to a collision of the needle with the needle plate and the hook body. Thus, lockstitch is not able to guarantee sewing without breaking the needle and deforming the needle tip.

Some additional advantages of the lockstitch type 301 are as follows:

- In forming a lockstitch, a standard needle with one long groove is used, as the needle does not participate in pre-tightening the loop of the top thread located in the previous stitch, as it happens in all existing technologies of forming chain stitches.

- In addition, the technology of forming a lockstitch by adjusting the tension of the threads can ensure a tight join of materials and qualitatively sew combinations of various materials, such as textile-leather, knitwear-leather, textile-plastic, knitwear-plastic, etc.

Therefore, at present, only a lockstitch of type 301 is used for this purpose, as it is impossible to achieve this with the help of existing technologies of type 401, where the looper carries the bottom thread.

It is impossible to find a denim trouser where the side long seam made with a double thread chain stitch type 401 provided a tight join of denim materials. Nor can double thread chain stitch type 401 stitch through plastic zippers, connected leather materials to textile and knitted materials.

For a tight join of materials with a double thread chain stitch of type 401, it is enough to tighten only the top thread strongly, as the threads are intertwined on the lower surface of the material and through the loop of the top thread passes two branches of the bottom thread.

In chain stitch of type 401 using a looper carrying the bottom thread, the point of the looper carrying the bottom thread enters the loop-overlap of the top thread, which is formed by the needle, i.e there is an input of the loop the bottom thread in a loop of the top thread. Not performing this process will result in skipping a stitch.

Then the needle comes out of the material and the material is fed to the length of the stitch and the needle with the top thread will make the next puncture of the material and begin to hold the top thread through the material.

To increase the reliability of this process, movable and fixed needle guards are used, as well as the maximum allowable gap between the looper point and the needle should not exceed 0.15 mm.

It is necessary to ensure that the loop of the top thread enters the loop of the bottom thread. This is ensured by the formation of a thread triangle, which consists of: a branch of the bottom thread, loop of the top thread worn on the body of the looper, the looper body.

In existing technologies of forming a double thread chain stitch, a thread triangle can be formed with the help of a looper performing a complex spatial movement or an oscillatory movement along the seam line, working together with spreader thread or oscillatory movement in a horizontal plane. If the needle with the top thread does not pass through the area of the thread triangle, then the stitch is skipped.

At the same time, reducing the length of the stitch leads to a decrease in the area of the thread triangle, and therefore, the minimum stitch length is limited to 1 mm, because with a stitch length less than 1 mm, the probability of not passing the needle through the area of the thread triangle increases, which will lead to skipping the stitch.

After passing the needle with the top thread through the area of the thread triangle, the looper returns back and drops the loop of the top thread from its body, and as a result, the loop of the top thread enters the loop of the bottom thread.

Which companies have come forward and partnered with you for the new sewing technology? Has the large-scale production begun yet?

I currently have no partners interested in commercially implementing my new technology. I am ready to cooperate on mutually beneficial terms with all manufacturing companies and investors that are interested in the commercial implementation of my technology, which may be of interest to many customers engaged in the production of various sewing products.

What would be the cost of implementing your sewing technology on machines?

Unfortunately, I cannot answer the question on cost at present, as I do not yet have a partner interested in the development and mass production of the equipment. (PC)