Celium has the potential to replace traditional leather in a number of applications

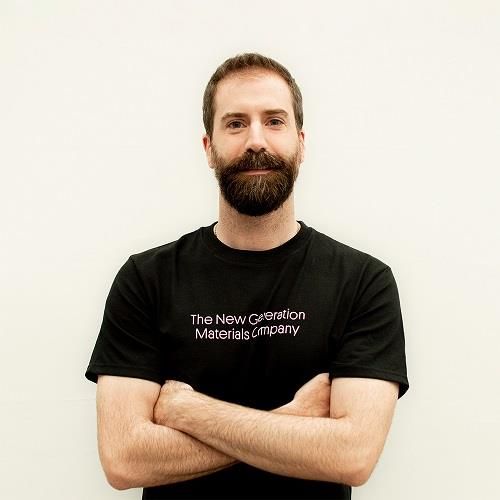

Polybion’s mission is to revolutionise the material world by growing premium, high-performance biomaterials from locally sourced fruit waste. The company strives to lead the biomaterials revolution by example, promoting circularity, regenerative economies, and a more sustainable future. Recently, GANNI Fabrics of the Future, the research arm of Ganni, has unveiled a game-changing blazer made entirely from Celium, a remarkable bacterial cellulose leather alternative developed by Polybion. In an interview with Fibre2Fashion, COO Diogo Frada talks about the biomaterial industry, the recent blazer made from Celium, and much more.

What is Polybion’s vision as a next-generation biomaterials company?

We want to be the next gen biomaterials company that brings performance and possibility to 21st century designers. We currently offer Celium—a bacterial cellulose leather alternative.

What sets Polybion apart from its competitors in the market? Are there any unique features or innovations that give your company a competitive edge?

We use bacteria instead of fungi or plant-based mixes to create Celium, our leather alternative, and we use locally sourced agro-industrial fruit waste as raw material (as food for the bacteria). So, we have developed a circular biomanufacturing platform to grow materials like Celium.

Due to its biological and organic nature, each piece of Celium can also be as unique and distinct as a fingerprint, lending it the hallmark of luxury. While cells self-organise into the cellulose structure, we turn into Celium, unrepeatable patterns and shapes arise, allowing nature’s own design to become a new golden standard for aesthetics. Whether you are looking for a classical leather feel or forward-thinking aesthetics, Celium can do both.

Another key differentiator is that we grow Celium in a proprietary state-of-the-art vertical biofabrication system similar to indoor farming that is very efficient and uses solar-powered electricity and heat, going from waste to finished material under the same roof to boost sustainability.

Could you elaborate on the key research and development initiatives that Polybion is currently undertaking? How do these initiatives align with the company’s long-term goals?

We are currently working to create a new realm of next-generation biomaterials or ‘bio metamaterials’, which are materials made using biological means and enhanced with synthetic biology, lab-designed materials that do not exist in nature, with entirely new properties. For example, although the exoskeleton of insects is made of chitin, and the cell wall of plants is made of cellulose, the magic of the bio revolution suggests combinations of these materials can be generated, i.e., complex networks of mixed bio polymers such as cellulose and chitin.

Can you share any notable partnerships or collaborations that Polybion has formed with other organisations, and how these collaborations contribute to the company’s growth and innovation?

Celium has resonated with forward-thinking, global consumer brands across multiple sectors, and we have engaged into collaborations with some of the world’s most iconic global consumer brands. Some of these collaborations are still confidential until the announcements.

About public collaborations, this year we collaborated unveiling the first bacterial cellulose prototype made by a major brand; a yellow blazer with GANNI.

This year, we also partnered with Fashion for Good, which is helping us to have support to validate our technology in preparation for implementation across the fashion value chain.

How does Celium differ from traditional leather?

Celium is a very interesting biomaterial with several potential benefits over traditional leathers. Here are some of the key differences between Celium and traditional leathers:

Source: Celium is made from bacterial cellulose, which is a biopolymer that is naturally abundant on Earth. Traditional leather is made from the skin of animals, which is a finite resource.

Environmental impact: Celium is a more sustainable material than traditional leather. The production of Celium does not require the use of animals or the extraction of fossil fuels. Traditional leather production, on the other hand, can have a significant environmental impact.

Properties: Celium has similar properties to traditional leather, but it can also be customised to have a variety of different colours and textures.

Cost: Celium is currently more expensive than traditional leather, but the cost is expected to come down as the technology matures.

Vegan and cruelty-free: Celium does not require the use of animals, making it a good choice for people who are vegan or who are concerned about animal welfare.

Overall, Celium is a promising new biomaterial that has the potential to replace traditional leather in a number of applications. It is a more sustainable, versatile, and customisable material that has the potential to reduce the environmental impact of the fashion industry.

How does GANNI’s blazer made from Celium contribute to sustainability in the fashion industry?

So far, it represents a significant milestone in the fashion industry, demonstrating that ready-to-wear applications made with bacterial cellulose leather alternatives are entirely feasible. The true contribution to sustainability will be realised once the product is on the shelf. We are actively collaborating with top global brands, including GANNI, to make this happen in 2024. Real impact requires scale, and substantial progress towards sustainability will occur as we become capable of releasing large-volume collections. We are diligently working to reach this crucial point in the industry’s evolution towards more environmentally friendly options.

What were the key features highlighted by GANNI during the Global Fashion Summit regarding the Celium blazer?

We loved this quote by Gabriella Onessimo from Fashion United, as it truly describes Celium’s Key features: “Recently debuted at GANNI’s Copenhagen flagship store during the Global Fashion Summit, the blazer features a marbled-yellow design adorned with silver buttons. The piece strikingly evokes the feel of traditional leather, from the textural details to the worn look.

Celium can be deemed a one-of-one textile, as it renders unique patterns upon completion of each finished piece. Its versatility in design allows it to be dyed, tanned, and embossed, making for a desirable material to work with that is further bolstered by its durability and lightweight feel.”

How does GANNI’s use of Celium in their blazer reflect the brand’s commitment to style and sustainability?

By introducing sustainable next-generation biomaterials into their supply chain and by making bold decisions that challenge the status quo in their industry like the blazer, GANNI demonstrates a vision of sustainability and a commitment to the circular economy and to a sustainable future.

In what ways does GANNI's showcase of the Celium blazer encourage consumers and industry peers to explore alternative materials in fashion?

The blazer was a demonstration of the transformative potential of bio-assembled leather alternatives in creating exceptional fashion pieces. It also captures Celium’s remarkable performance and unique appearance.

With this exhibition, GANNI shows other industry peers that creating a blazer made completely out of a bacterial cellulose leather alternative is possible and it motivates them to try it too.

Considering the fast-paced nature of the biomaterial industry, how do you stay updated with the latest advancements and trends? How do you ensure that your products remain relevant in the market?

We have an active research and development team to continue optimising our processes and reach the performance and characteristics for the desired applications with Celium and to explore new potential applications.

Also, the expertise and perspectives of industry leaders such as the brands we work with are vital pillars within our iterative and R&D processes, empowering us to refine our materials, elevate product standards, discover brand new applications, and contribute to a better world with sustainable material alternatives.

Data security and privacy are crucial in the biomaterial field. How do you prioritise the protection of sensitive data and ensure compliance with relevant regulations?

We are as transparent as we can in terms of our technology and biomaterial content. As for our secret formulas, our patents are filed already. To ensure that our intellectual property is safe, we usually sign Non-Disclosure Agreements and Material Transfer Agreements when a partnership or collaboration requires further information.

Also, communication-wise, we take deep care in being completely transparent about our materials, processes, and company.

Looking ahead, what are the company’s future plans for growth and expansion? Are there any upcoming projects, partnerships, or strategies that you can share with us?

Our future plans in the short term are to continue optimising our processes and production ramp-up until we reach our current facility’s maximum capacity (1.1 million sq. ft. of Celium) and to make our current collaborations a complete success by making sure we strive for greatness in our material offerings to brands.

In the mid-term, we are working on the design, engineering and manufacturing of our next facility, FOAK 10X which will be a fully automated and solar-power facility that will allow us to reach over 10 million sq. ft per year, a breakthrough production-output for a biomaterials company.

As the biomaterial industry continues to evolve rapidly, what skills or qualities do you believe are essential for professionals seeking to succeed in this field, both now and in the future?

Some key skills and qualities that will always be important for biomaterial professionals, regardless of the specific changes that occur in the industry are strong scientific and technical skills, problem-solving, communication and collaboration skills and also very importantly, adaptability. The biomaterial industry is constantly changing, and biomaterial professionals need to be able to adapt to these changes.

In addition to these essential skills and qualities, biomaterial professionals should also be passionate about the field and committed to making a difference in the world.