Canada's Lululemon unveils new enzymatically recycled polyester gear

Insights

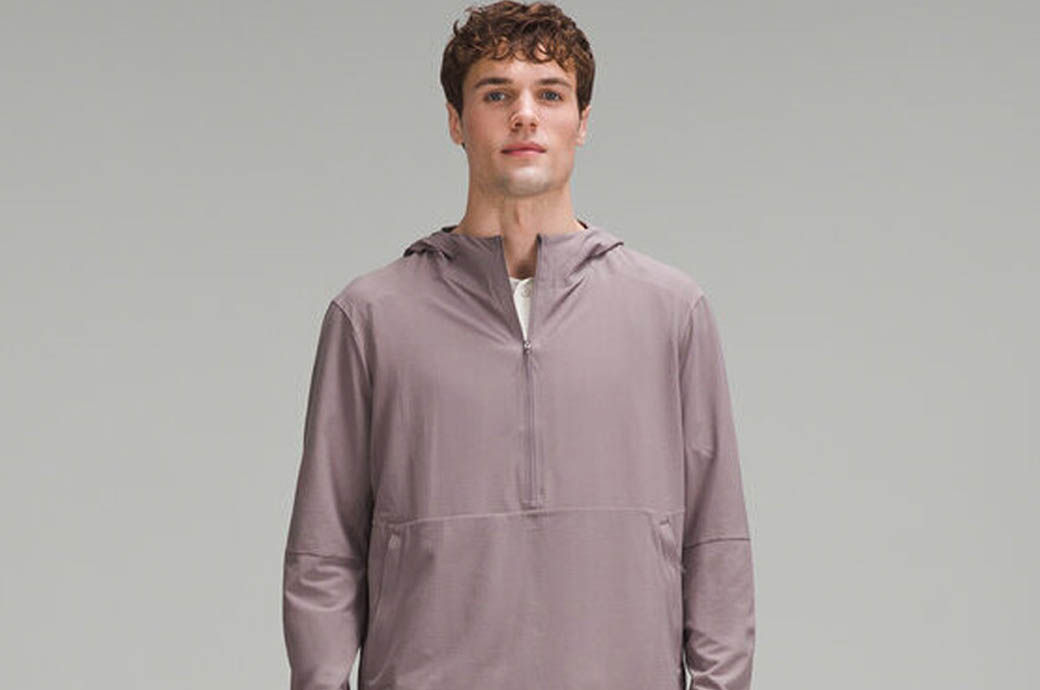

- Lululemon launches its first product, the Packable Anorak, made with enzymatically recycled polyester in collaboration with Samsara Eco and LanzaTech.

- This innovation marks a milestone in textile-to-textile recycling, reflecting the company's commitment to circularity.

- The anorak embodies sustainability by using recycled plastic, and captured carbon emissions.

Featuring polyester made from a combination of bioprocessing technologies, including enzyme-based recycling from Samsara Eco and captured carbon emissions from LanzaTech, the new material process behind the high-performance jacket delivers the same feel and quality as the lightweight, quick-drying material lululemon guests love.

Samsara Eco’s technology harnesses patented enzymes to break down complex synthetic blends that are core to lululemon products and the performance apparel industry. LanzaTech specializes in capturing carbon emissions from industrial facilities and converting them into building blocks for polyester. Together, these innovations fuel a new way to produce polyester.

The Packable Anorak illustrates the Company’s end-to-end vision of circularity by using a variety of inputs, including mixed plastic waste, lululemon apparel at the end-of-life stage, and converted carbon emissions. Designing for circularity is a core consideration of the Company’s product philosophy, with the goal to maintain the highest value and maximize use for as long as possible before recycling into new products.

“Our vision is to scale these technologies to address textile waste across our entire supply chain,” said Yogendra Dandapure, Vice President, Raw Materials Innovation at lululemon. “This capsule product is a first step along this journey, helping us test and learn as we continue to advance circularity, which signals exciting possibilities for all industries looking to shift to more circular models.”

"Putting an end to fashion waste is critical to addressing the climate crisis. Our enzymatic recycling technology addresses the issue by putting waste to work, extracting fibres from old textiles and repurposing them for a next life. We're proud to be working with lululemon to create change and disrupt the linear economy of plastic. The Packable Anorak shows the potential to give clothes an infinite life and prevent textiles from ending up in landfills," said Paul Riley, CEO and Founder of Samsara Eco.

Building on the Company’s world’s first enzymatically recycled nylon 6,6 announcement, in partnership with Samsara Eco last month, this milestone is another way lululemon is advancing its goal to make 100% of products with preferred materials and end of use solutions by 2030.

Note: The content of this press release has not been edited by Fibre2Fashion staff.

Fibre2Fashion News Desk (RM)

-Ltd..jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)