“At this year’s ITMA 2023, it was clear that many new technologies are being developed that will do much to reduce resource consumption, but the reality is that faced with extremely tight margins, many textile companies are not in a position to invest in new capitally-intensive projects,” said BTMA CEO Jason Kent. “Outdated but mechanically sound machines used to be simply scrapped, with few other options, but this has now completely changed.”

The company’s widely-emulated Plant Explorer central control system sets the standard around the world for automation, with powerful features and ease of use, pulling together the control and monitoring of entire production plants and storing it in a standard Microsoft SQL Server database, BTMA said in a press release.

“We have successfully automated many makes and types of dyeing machines and found that the flexibility of PC-based controllers has allowed us to help customers in other parts of the dyeing and finishing plant as well, including with stenter frames and dryers. Our non-proprietary approach means that all this equipment can be monitored from a simple web-browser on the company network, while sophisticated integration and automation is going on in the background. Smart-coupling and joint-scheduling are standard features on these controllers, making it simple for supervisors and operators to run whatever batch sizes are needed,” said managing director Richard Armitage.

In a recent project, FTS Dyers, based in Langholm, Scotland, has had its existing radio frequency dryers fully rewired and equipped with new PLC control and sensors by Adaptive. Many of the original parts on these machines have been replaced over the years, with their longevity down to a skilled team of engineers. Now, however, they have been fully automated and connect with similarly upgraded dyeing vessels and controllers all linked to a central computer system.

“Many of the machines we have successfully upgraded date back to the 1970s and some of them go as far back as the 1950s,” added Armitage.

Working with fellow BTMA member Roaches International, Adaptive also supplies software packages and control panels for the automation of autoclaves and curing ovens used in the manufacturing of advanced composites. Many companies in the field of Formula 1, marine and aerospace have benefited from these upgrades.

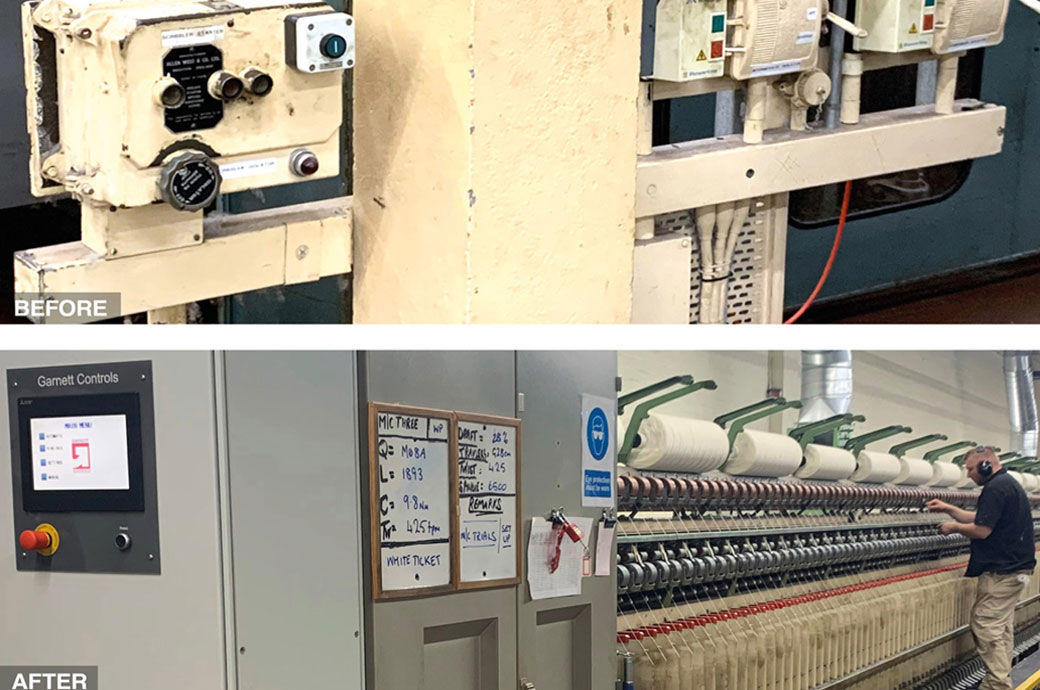

Garnett Controls has been a pioneer in the retrofit market since 1990, with an unrivalled number of installations in the fields of blending, carding, nonwovens, and spinning. Well proven systems include the Microweigh XL and Rollaweigh weight control systems which have become the industry standard.

In blending, the Lubric8 fibre lubrication system has been integrated into many existing blending plants to deliver the precise application of fibre lubricants, anti-static solutions, and process additives.

The company also leads in the development and implementation of digital drive systems to replace conventional drives on textile and nonwoven machines, to achieve precise synchronisation with optimum energy efficiency. The latest retrofit drive systems come with sophisticated data collection to continually monitor and record performance whilst providing easily accessible historical information. The systems are supported both through a well-established network of agents and associates as well as directly via remote access.

“We’ve been installing the most advanced retrofit drive systems internationally for many years and we continue to develop our products as new technologies emerge,” said managing director Mark Baldwin. “Our retrofit systems are fully supported internationally by an experienced team and customers have reported achieving energy savings of up to 40 per cent depending on the type of machine.”

Tatham is another BTMA member offering retrofit services for OEM carding machines, crosslappers, needlelooms, blending systems, spinning frames, and twisting and winding units.

The company’s TS Drive System is designed to run the motors at their optimum performance levels enabling considerable energy savings in the region of 30 per cent to be achieved.

“TS Drive Technology is the most advanced product on the market for synchronous drive applications,” said director Tim Porritt. “It provides superior performance and accurate speed regulation even at low speeds.”

Moisture measurement and control systems which are retrofitted onto a wide range of production lines are the specialism of Streat Drycom. The Drycom system continually measures the moisture content of textiles and nonwovens during production and automatically controls the energy and/or speed of ovens and dryers in order to maintain the optimum moisture content.

“Moisture content is a critical factor in many sectors,” said managing director Alan Brydon. “Too much moisture in the product can result in processing issues which affect quality and can attract mildew. Too little moisture can damage fibres as well as being a significant and unnecessary cost of energy. Both affect true invoice weight which has a direct influence on profitability.”

Applications include ovens and dryers in the field of natural fibre scouring, cotton bleaching, latex curing in carpet backing, yarn setting lines, and spray systems. Drycom is unique in that specific calibrations can be derived for different fibre types, additives, and environmental conditions, thereby always providing optimum accuracy, efficiency, and control.

“Most machines already in operation worldwide function flawlessly mechanically and BTMA members can offer many options via upgrades and automation to secure their production going forward, ensuring a sufficient margin of profit is retained by keeping them going. The cost-effective longevity of retrofitted machines makes sound and sustainable sense,” added Kent.

Fibre2Fashion News Desk (NB)