OQ Chemicals achieves milestone in Bay City with Propel project

Insights

- OQ Chemicals has completed its 'Propel' project in Bay City, TX, aimed at expanding its portfolio by producing high-purity propionaldehyde.

- The project, supporting Röhm's new MMA plant, was completed on schedule, reflecting strong collaboration.

- Röhm's plant employs LiMA technology for efficient MMA production, setting new standards in resource efficiency.

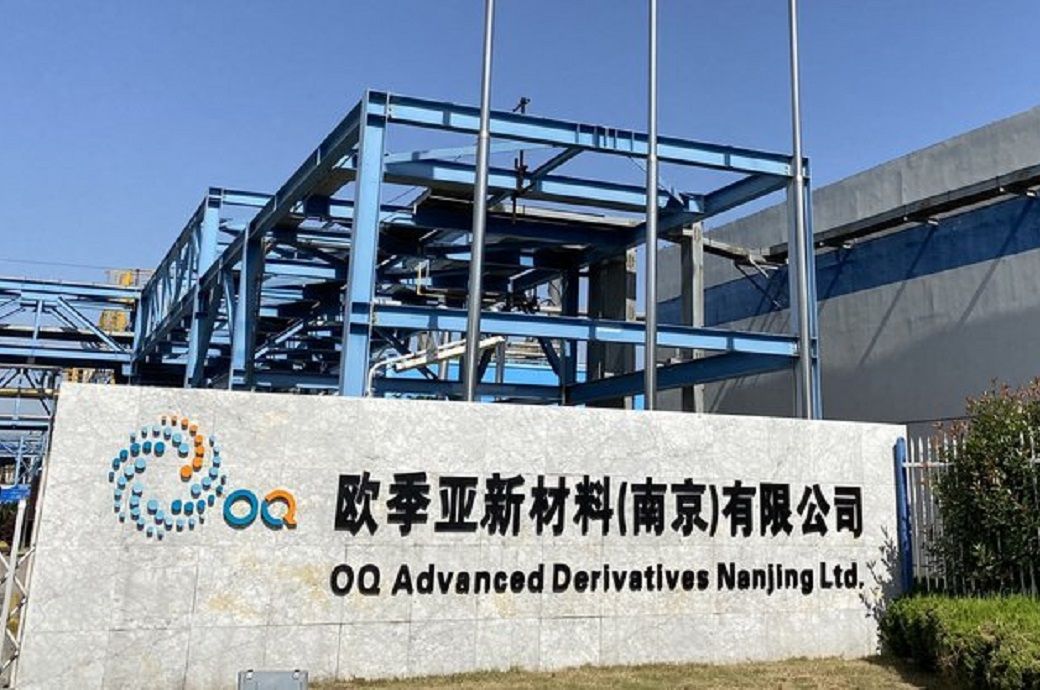

In a significant development, OQ Chemicals has achieved mechanical completion in its ‘Propel’ project, short for ‘Propyls Elevated’, at its Bay City, TX, production site. This project is a crucial part of OQ Chemicals’ strategy to expand its portfolio of applications. It comprises key infrastructure and services, including the production of high-purity propionaldehyde, a key raw material. The project supports the operation of Röhm’s new state-of-the-art worldscale Methyl Methacrylate (MMA) plant, which is integrated into the Bay City site. Propel was completed on schedule with zero lost time or Occupational Safety and Health Administration (OSHA) recordable incidents from all entities involved, including OQ Chemicals, contractors, and partners.

“This accomplishment reflects the dedication and excellent collaboration of our OQ Chemicals’ team, various partners, contractors, and stakeholders who were all instrumental in reaching this critical milestone. The project team is particularly proud of the safety culture demonstrated by everyone involved, which was paramount for achieving this exceptional safety performance,” commented OQ Chemicals project director, Markus Heuwes.

In October 2022, Röhm and OQ Chemicals initiated the joint project. The new plant is the first to employ Röhm’s proprietary LiMA technology (‘Leading in Methacrylates’), for the production of MMA, a crucial precursor for applications like coatings, adhesives, medical products, and road markings. The LiMA technology sets new standards in resource efficiency and reduces environmental impact. Simultaneously, OQ Chemicals began constructing infrastructure and services vital for Röhm’s plant operation.

“Achieving mechanical completion underscores OQ Chemicals’ commitment to delivering projects on time and to the highest quality standards. As we move forward, our focus remains on the final phases of the project, including commissioning, testing, and handover. We are committed to ensuring a seamless transition to operational readiness, so that our partner can realize the full potential of their investment,” said Kyle Hendrix, OQ Chemicals president USA.

Note: The content of this press release has not been edited by Fibre2Fashion staff.

Fibre2Fashion News Desk (HU)

-Ltd..jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)